DartfulDodger

Active Member

- Joined

- Oct 24, 2009

- Messages

- 40

- Reaction score

- 0

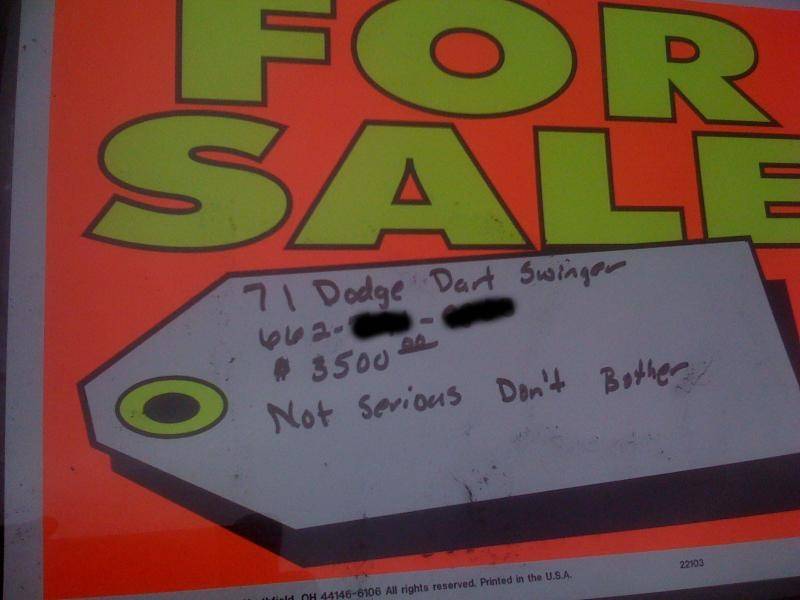

Hi all! I introduced myself on the "Welcome Wagon". I'll begin posting the progress of my current build...a 1971 318 Auto non-air Swinger. I've always been a B-Body guy but have been guilty of picking up A's that come across my path. This one showed up for sale in a parking lot several blocks from my store here in Tupelo. It was so solid and straight that I couldn't refuse it!

It didn't take but a few days before the tear down began...I just can't leave well enough alone.

Non-original 318 pulled. Hell,....everything pulled!

It didn't take but a few days before the tear down began...I just can't leave well enough alone.

Non-original 318 pulled. Hell,....everything pulled!