You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

273 rockers on 340 with hydraulic cam

- Thread starter Mtrhead

- Start date

-

After I use a pushrod checker I will be using Mancini's cut to fit pushrods like PA Dodger advised seems like how can you go wrong with a kit like that ...thanks everyone for helping me solve this Mopar mystery tonight....

That's a goodun! I tell you man, with a camshaft of that size, you need to contact Mike at @B3RE B3 Engines and let him walk you through how to properly locate your rocker shafts. You will NOT regret it. I tagged him so maybe he'll chime in, but if not, here's his web site with contact info there. I would consider it imperative that you do it. It's WELL worth the money!292/509

B3 Racing Engines LLC - Performance Engine Building and Mopar Valvetrains

Don't get pushrods until you get your rocker shafts properly located. It's THAT important with a camshaft of that size.After I use a pushrod checker I will be using Mancini's cut to fit pushrods like PA Dodger advised seems like how can you go wrong with a kit like that ...thanks everyone for helping me solve this Mopar mystery tonight....

View attachment 1716120213

You will have great results! Mike is a legend genius! He fixed me up with my unicorn slant 6 head after I put the 318 valves in it. They are .300" longer than the slant 6 valves and required a good bit of correction for the rocker shaft location, so I have first hand experience with Mike's expertise. He's top notch.Will do triple R

You will NOT be disappointed!I've heard about his geometry correction kits and have been meaning to use something like that and finally get a well oiled machine type 340 that runs semi friction free

Thanks! She's a hoot to drive and the unicorn head motor ain't even in her yet! I'm assembling it now!With the way Vixen sounds I would put money on it that was a 273 with the hypo manifolds and the resonated barracuda tip...unreal raspy lil car...bet she's fun

PA Dodger

Well-Known Member

Just a general word of caution-don't assume. Check everything out. The 273 arm assemblies I bought were oddball (maybe very early production?) that had the shaft oiling holes clocked way different than anything I had ever seen. Somewhere around the 4:00 position instead of at the bottom. I redrilled my shafts and banana grooved them at the same time.

I think you're definitely on the right track!I'm definitely figured out I'm going to get shafts from rocket that are thick hard chromoly steel with banana grooves

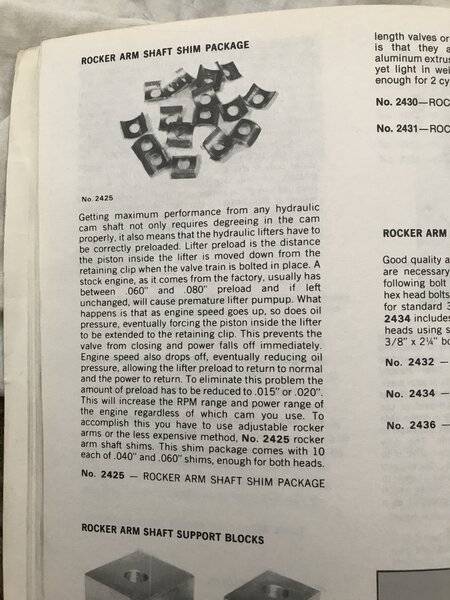

ED Hamburger used to sell a shim package for decreasing the factory lifter preload when using a hydraulic cam and NON ADJUSTABLE rocker arms.

The shims were used to increase RPM range, and horsepower without switching to an adjustable recker setup. A cheap way to avoid lifter pump up. 1980 tech

The kit came with 10 each: 0.015", 0.040", and 0.060" shims

Don't know why they would be used with 273 adjustable rockers-backyard engineering?

I should still have a magazine write-up on this somewhere.

The shims were used to increase RPM range, and horsepower without switching to an adjustable recker setup. A cheap way to avoid lifter pump up. 1980 tech

The kit came with 10 each: 0.015", 0.040", and 0.060" shims

Don't know why they would be used with 273 adjustable rockers-backyard engineering?

I should still have a magazine write-up on this somewhere.

81/82 catalog

Mancini has them. That's where I got mine for my 273. Rocker Shaft Shims

The difference between the Hamburger and Mancini shims and the B3 shims is the B3 shims actually relocate the rocker shaft. They don't just raise it. They raise AND move it.

mopowers

Well-Known Member

How much can the rocker shaft be moved before you have to mill the holes in the shaft?

I run 273 adj. rockers on my 340 with the 508" lift purple shaft cam. I am using crane cam adjusters on them with jamb nuts. My block has been milled for zero deck height and the heads have been milled slightly, I measured and used custom push rods from these guys: oepushrods.com

Sometimes you have to elongate the holes, if the correction is a lot. I had to do that on my slant 6.How much can the rocker shaft be moved before you have to mill the holes in the shaft?

I bet that's a runnin motor scooter! You got any videos of it? I'd love to hear it.I run 273 adj. rockers on my 340 with the 508" lift purple shaft cam. I am using crane cam adjusters on them with jamb nuts. My block has been milled for zero deck height and the heads have been milled slightly, I measured and used custom push rods from these guys: oepushrods.com

65Val

Average Length Member

Probably someone was too cheap to buy new pushrods to use those rockers with hydraulic lifters, which are taller than solids. Spacing up the shafts gave enough clearance to run hydro's with the solid lifter pushrods. Seen this before...actually works, but not correct.But why are they there and what were they used for

ajarofclay

Well-Known Member

I've got the same application in my Demon. Did it 45-50 years ago. Can't remember where if got them but it was just a matter of buying cupped HiPo aftermarket pushrods off the shelf.

BillGrissom

Well-Known Member

I installed a hydraulic camshaft in my 1965 273 engine, a fairly mild "RV/Torque" camshaft (still has slightly more intake lift than factory HiPo camshaft, I recall). I bought standard pushrods for the 1970's 340 TA engine, which are similar ball & cup type as my factory pushrods, but just shorter to fit the hydraulic lifters. Might work for others using fairly standard parts like heads which haven't been milled much.

-