There is a guy at our local strip, that in a hurry-last minute-get it together moment ran one 318 head and one 360 head on a 360. He was in it for points and needed to run. Went low 12's in a 65 fish....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

302 heads

- Thread starter ktcnn94

- Start date

-

There is a guy at our local strip, that in a hurry-last minute-get it together moment ran one 318 head and one 360 head on a 360. He was in it for points and needed to run. Went low 12's in a 65 fish....

Totally sounds like something I would do lol. Go big or go home. That is the Mopar way after all. I'm like Ricky Bobby, I live my life by that saying. Also, I just wanna go fast!

Infecteddog

Well-Known Member

All hardened seat heads are prone to cracking from the mid '70s to now. Iron cracks, aluminum warps.ok thanks, are they prone to cracking? if so is it something I can see with close inspection?

I would skip over them every time for something that's supposed to make power, especially if money had to be spent. My running them- it was more worthwhile having lower CR. Motor woulda been pretty decent had I put 360 heads on it. Might they be worthwhile? Sure. But if you're gonna run 318 heads there isn't really much difference in them. In stock form none are very good or better than each other. A better cam and converter would be a much more worthwhile investment than machining 302s.Oh for God's sake. Do yall have to split frikkin hairs about everything? The 302 heads are designed for the 318. I bet some of yall have never run the damn things before. I have. On both a 318 and 360. They ran fine. They have plenty enough potential to get 325 or more HP on a 318 with good parts choices.

The smog 360 heads do almost the same job of supporting power as the pre-smog 360/340 heads and the 308s excel in some areas. But those were larger port heads than the 302s that were more meant to be ported and run.They are a fine and dandy head for a stockish build but I wouldn't expect any real power come on guys let's call it what it is they are smog heads never had any intent on supporting power they were designed for fuel efficiency and lowered emissions

Cars, trucks, vans, don't matter- '85+ 318s had 302s unless they had 360 heads. Trucks, vans got flat tappets before TBI though.302's are for cars, but isn't there the same style heads that were used for truck engines?

Thanks Dave for the great write-up and info!

Thought I'd add a little data to this discussion. First we all know that bigger, better flowing heads make more power, but there is a lot of other stuff that has to go into the combination to exploit heads that flow 270-320 CFM @ 0.600" & 28" of water.

So, say your running a dual plain intake, and 8.8-10.5:1 compression, want to run pump gas, have a nice wide torque curve, don't want to spin the motor past 7000, and aren't running a stroker... Now a smaller head may begin to make more sense. So how much power can you get out of a ...302 casting? That depends on the flow available at the intake valve, so here are some numbers (all @ 28" of water):

STOCK 302 1.78"/1.5" (Shady Dell)

0.100" 62.8 NA

0.200" 125.6 70.9

0.300" 158.4 92.8

0.400" 169.3 99.6

0.450" 170.6 101.0

0.500" 170.6 102.4

0.550" 170.6 102.4

0.600" 170.6 102.4

As Cast "302" 1.78"/1.50" (MD Performance Center)

0.100 51.8 36.5

0.200 92.5 70.7

0.300 130.1 104.3

0.400 163.9 113.2

0.450 169.1 115.2

0.500 170.4 117.3

0.550 172.2 119.0

0.600 172.5 120.4

Ported

"302" 2.02"/1.60" (Shady Dell)

0.100 71.8 42.5

0.200 148.4 86.3

0.300 212.2 113.9

0.400 241.5 131.1

0.450 244.6 137.7

0.500 246.7 139.7

0.550 242.6 144.9

0.600 240.8 144.9

Ported "...302" Heads 1.94"/1.60" (Shady Dell)

on a 4.040" Bore (heads currently on my Dart's

0.050 over 318 (326Cid):

LIFT IN / Out

0.100" 66.1 / 48.4

0.200" 132.8 / 90.4

0.300" 189.9 / 126.2

0.400" 218.4 / 148.8

0.450" 227.9 / 152.9

0.500" 232.8 / 159.8

0.550" 238.0 / 163.9

0.600" 239.1 / 169.8

Same 1.94/1.6 302 head on MPC's bench on a 4.030" Bore

LIFT IN / EX

0.100" 65.7 / 49.6

0.200" 128.6 / 94.5

0.300" 174.7 / 130.6

0.400" 208.6 / 157.5

0.450" 216.6 / 166.0

0.500" 205.7 / 171.1

0.550" 210.0 / 173.3

0.600" 213.1 / 173.2

Some other Small chamber heads:

273 Cleanup Port/Valve Job 1.78"/1.50"

(pretty much a "stock" class vavle job)

0.100" 49 43

0.200" 98 85

0.250" 124 100

0.300" 145 112

0.350" 162 120

0.400" 179 125

0.450" 188 129

0.500" 190 132

0.550" 185 134

0.600" 177 135

273 Ported 1.88"/1.60" (note the biggest intake

gains are at lower lift, suspect the intake valve get's

shrouded against the side of the combustion

chamber at higher lifts):

0.100" 60.93 48.78

0.200" 122.75 99.78

0.300" 179.68 137.16

0.400" 197.02 157.11

0.500" 185.91 168.20

0.600" 187.24 179.29

So how much power can a stock 302 head support? Well they flow roughly 170 CFM @ 0.500 & 28" of water, the thumb rule for this is:

Horsepower per cylinder = .43 x airflow @ 10" of water,

.275 x airflow @ 25" of water, or

.26 x airflow @ 28" of water.

So 0.26 x 170 x 8 = 353 HP at the crank (if everything is optimized you

might be able to 10% better, say 385 HP).

What is the impact of porting on this? Taking the average of MPC and Shady Dell's numbers we get 226 CFM @ 0.600" and 28" of water:

0.26 x 226 x 8 = 470 HP at the crank (again, if everything is optimized you

might be able to do 10% better, say 523 HP).

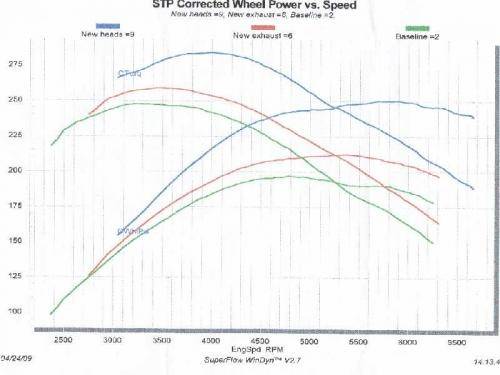

So that's theory, how'd it really work out? Below are a series of chassis dyno plots (all for the same short block and intake manifold (LD4B)). The first set of three shows a baseline (Green) with 9.1:1 compression, unported 302 heads, 0.420" lift mech cam, and stock early A-body exhaust manifolds dumping into a single 3" exhaust, 750 Holley. The Red trace shows the impact of TTI headers, 3"-in-2.5"-out X-pipe, glass packs dumping in front of the rear wheels, and Hughes roller rockers. Next (Blue) is the swap to the ported 302 castings, with a 0.005" clean up cut these cc'd slightly smaller than the unmolested 302s and bumped the compression to 9.25:1. A tidy gain of 54 Hp and 46 FtLb without so much as pulling off the water pump. So Time for a Cam...

The Existing cam was a flat tappet Mechanical:

Intake Exhaust

Valve Lift 0.420" 0.420"

Advertised Dur: 262° 262°

Dur @ 0.05" Lift: 219° 219°

Lobe Sep: 110°

Intake Center Line: 106°

The new cam is a Comp Cams Mech Roller:

Lift: 0.630" 0.630"

[email protected]": 254° 260°

AdvDur(@0.006"): 284° 292°

LSA: 107°

Int Center Line: 102°

Lash: 0.022"-0.024".

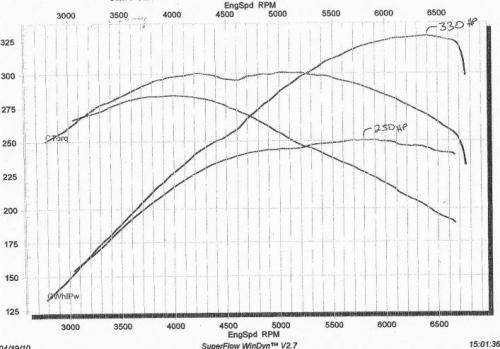

Additionally the heads were milled 0.030, which netted roughly a 10.1:1 CR, and we replaced the vacuum secondary 750 Holley with a QFT 750 Double pumper... The second image below (black & white plot) compares the blue plot from the previous graph to the results of the cam, compression, and carb change; net 85 HP & 15 FtLb

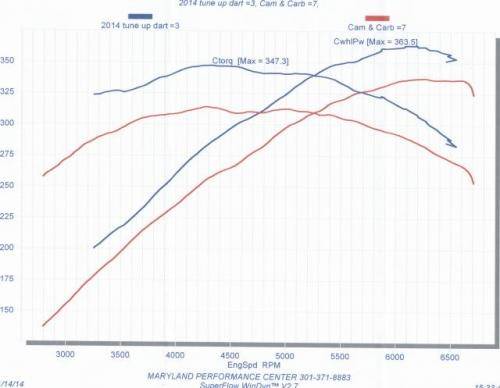

Sooo, then I hurt the motor and we rebuilt it with lighter forged pistons (previously was 0.045"over KBs about 0.020" down the bore), a 0.050" over bore (only needed a 0.005" hone to clean up), a compression ratio of 10.25:1, and Harland Sharp rockers replacing the Hughes rockers which were getting tired too quickly in this application (road race/street). I added a 0.5 partially open carb spacer and we also replaced glass packs with some 16" long oval Borla mufflers (quieter!). This netted another 33 Hp and 47 FtLb (the blue traces on the final graph). Still digests pump 93 gas.

Is there more there with better heads and intake, you bet, but this is plenty to pull to 150MPH on the front straight at Summit Point. My rule book is a little restrictive, I have to use a 273/318/destroked 340 (less than 5000cc), Iron heads, and one of the following manifolds: LD4B, LD340, Performer, or Performer RPM.

So the final question might be, what would the stock 302 heads be like on a 360? Another Thumb rule says:

RPM at peak horsepower = (N / one cylinder displacement (ci)) x CFM

N = 2,000 @ 10" of water

N = 1,267 @ 25" of water

N = 1,196 @ 28" of water

So a 0.030" over 360 cylinder = 45.66 ci

(1,196 / 45.66) 170 = 4452 RPM

and Ported:

(1,196 / 45.66) 226 = 5919

and a .045 over 318 = 40.66 ci

(1,196 / 40.66) 170 = 5000 RPM (in the real world with headers it peaked about 5300)

and Ported:

(1,196 / 40.66) 226 = 6647 (ITRW It peaked about 6300)

So yes, you could make more power with better heads, but looking at the torque curves and considering the throttle response that a high flowing but smaller port can provide, the high turbulence/quench combustion chambers also provide greater efficiency and tolerance for lower octane fuel, so there is a place for the 302 head in a street performance or moderate competition build.

Dave

The mopar performance clearly stats that on a low compression 340 that the 392 head is worth 25 hp over an X head. Kim

stixx

Well-Known Member

When was that? Probably advertizing because they wanted to promote the new "Swirl Port" head (Nineties?)

In stock form a 302 flows worse than a stock L or X head. The EQ on the other hand is a different story.

In stock form a 302 flows worse than a stock L or X head. The EQ on the other hand is a different story.

Tbone416

Well-Known Member

Since you're going with 302 or 741 heads.. you might as well go with hydraulic roller cam. The heads are already have big push rod holes and retrofit lifters are cheap now. It might save you some headaches with cam break in. A little port matching and Bowl job and a bigger valve will help. Be sure to look out for valve shrouding. All that being said Magnum swap will make more power but cost more.

When was that? Probably advertizing because they wanted to promote the new "Swirl Port" head (Nineties?)

In stock form a 302 flows worse than a stock L or X head. The EQ on the other hand is a different story.

Well yeah, the 302's in stock form have the smaller 1.78/1.50" valves and 318 ports, so, you can't compare them to X or J heads which never had anything smaller than 1.88/1.60" valves and had the larger 340/360 ports. You can compare the 308's to the X and J heads, and they're about the same on the intake side. The exhaust side is where the "swirl port" heads are better. The 302's are only interesting because they have closed chambers (308's are open chambers like the X and J heads). They're a nice improvement in compression when used on a mild 318, especially considering how low some of those engine are for compression from the factory. But if you start modifying stuff they're still a 318 head, you need to add bigger valves, port work etc and by the time you've done that you might as well have bought an aftermarket head nowadays, you'd have no more money involved and you'd have heads that have a lot more potential. 302's are really only a worthwhile upgrade if you're planning on bolting them on in fairly stock form (unless you can do the machine work yourself), and it's really just about the increase in compression, not a dramatic improvement in cfm for the heads. They were a lot more interesting/useful before there were a bunch of different aftermarket heads available like there are now. Better to just buy a set of EQ's, or even stock magnum heads for a mild build now. Smaller chambers AND bigger valves and better flow.

Tbone416

Well-Known Member

Hay guy's let us not forget that the guy that started this post is building a 318. Not a 408 or a 360. So the port volume only has to fill that small cylinder. And a 302 head was designed for a 318 motor this head will work fine for what he needs.

I have a sneaky suspicion that a lot of the naysayers have not run the 302 heads.

Just to make it clear, I'm not bashing the 302 heads. I think they're a good option for mild to moderate 318's. They're a great way to raise compression on a 318 with the earlier open chamber heads, and that will definitely help power. If you have a good bottom end they can be a nice little upgrade without doing a ton of work.

All I'm saying is you can't compare the 302 head flow numbers to 340/360 head flow numbers. And like ANY stock head, if you're planning on a lot of machine work- bigger valves, porting etc it's worth taking a long hard look at all the aftermarket heads on the market now. Because unless you do the head work yourself you'll end up paying as much as it would cost to buy a set of EQ's or similar.

The other thing is that a set of stock magnum heads would work better than the stock 302's if you're willing to change over to oil through lifters and pushrods and other magnum gear (intake, valve covers, rocker gear, etc). Not as easy as a 302 swap on an LA engine because of the magnum gear, but better compression, flow, bigger valves.

All I'm saying is you can't compare the 302 head flow numbers to 340/360 head flow numbers. And like ANY stock head, if you're planning on a lot of machine work- bigger valves, porting etc it's worth taking a long hard look at all the aftermarket heads on the market now. Because unless you do the head work yourself you'll end up paying as much as it would cost to buy a set of EQ's or similar.

The other thing is that a set of stock magnum heads would work better than the stock 302's if you're willing to change over to oil through lifters and pushrods and other magnum gear (intake, valve covers, rocker gear, etc). Not as easy as a 302 swap on an LA engine because of the magnum gear, but better compression, flow, bigger valves.

BigBlockMopar

BigBlockMember

Hay guy's let us not forget that the guy that started this post is building a 318. ...

That was 2 years ago. Engine should be well up and running by now.

Unless that is, his planning and build progress resembles mine

Tbone416

Well-Known Member

Your right I didn't see the post date. I guess we're just talking.That was 2 years ago. Engine should be well up and running by now.

Unless that is, his planning and build progress resembles mine

Its all good info whether old or not.

Your right I didn't see the post date. I guess we're just talking.

-