Yeah but... you're gonna spend $300-400 getting that crank reground. If it were me, id try to just get the block and buy an aftermarket forging 4" stroke. Would cost a bit more initially but you'd be happy with the torque. But that's me.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

340 questions

- Thread starter abodyjoe

- Start date

-

abodyjoe

Well-Known Member

don't want a stroker.

Fair enough get that baby reground!don't want a stroker.

abodyjoe

Well-Known Member

i picked the motor up tonight. as longs as i measured right its std bore. the rods with no pistons are the original rods. the pistons and rods the seller got from a friend. steel crank drilled for a pilot bearing.. got a windage tray, oil pan and timing cover with it. now i just have have to figure out how to build it. want it to run like a 340 is supposed to and be a nice cruiser with the 3.23 gears that are in the car. I'll use the 340 manifolds i have on the car now along with the performer rpm (non air gap) intake i have. I'll also use one of the sets of J heads i have.

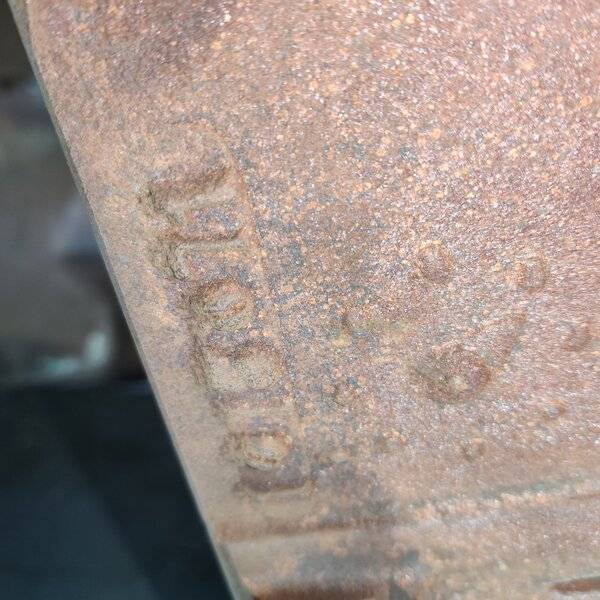

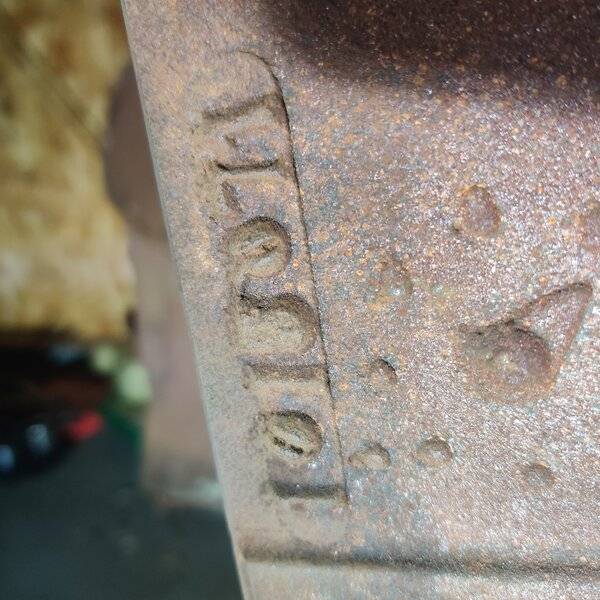

casting date looks to be 1-13-71 or maybe 1-15-71. not sure what the vin is from.

casting date looks to be 1-13-71 or maybe 1-15-71. not sure what the vin is from.

Nice score! are you having the short block built to blueprint specs?

abodyjoe

Well-Known Member

no idea what i want to do to be honest.Nice score! are you having the short block built to blueprint specs?

Keep this in mind, though. Forged crank ain't an end all be all. Chrysler used nodular cast iron, like Ford and not just grey cast iron like GM for their cast cranks. They are much stronger than people give them credit for. The Chrysler cast cranks will take 500 plus HP properly prepped. So if it's a cast crank engine, all is not lost.ok/ that helps a ton

abodyjoe

Well-Known Member

i agree. plenty of fast 360 motors out there and they never had a steel crank. for what I'm doing I don't need it to be steel.Keep this in mind, though. Forged crank ain't an end all be all. Chrysler used nodular cast iron, like Ford and not just grey cast iron like GM for their cast cranks. They are much stronger than people give them credit for. The Chrysler cast cranks will take 500 plus HP properly prepped. So if it's a cast crank engine, all is not lost.

340, forged, shot peened crank. Nice score!

That's a clear 71 engine. Crank should be forged if it's still the matching one.i picked the motor up tonight. as longs as i measured right its std bore. the rods with no pistons are the original rods. the pistons and rods the seller got from a friend. steel crank drilled for a pilot bearing.. got a windage tray, oil pan and timing cover with it. now i just have have to figure out how to build it. want it to run like a 340 is supposed to and be a nice cruiser with the 3.23 gears that are in the car. I'll use the 340 manifolds i have on the car now along with the performer rpm (non air gap) intake i have. I'll also use one of the sets of J heads i have.

casting date looks to be 1-13-71 or maybe 1-15-71. not sure what the vin is from.

View attachment 1716030637

View attachment 1716030638

View attachment 1716030639

View attachment 1716030640

Standard bore 340 block is hard to find. If it is easy 1000 just for the block around here.

justinp61

Well-Known Member

- Joined

- May 15, 2009

- Messages

- 3,146

- Reaction score

- 4,149

Years ago I bought a 72 340 Duster that was very tired. I rebuilt it standard on the bore, installed a set of early pistons, 2.02" valves in the J heads and a small MP hydraulic cam, 274/474, or something close. It was a numbers match car, so I kept the stock intake and exhaust manifolds. With 3.55 gears it ran very well and was a hoot to drive.

abodyjoe

Well-Known Member

Standard bore 340 block is hard to find. If it is easy 1000 just for the block around here.

damn! someone wants to give me that for it I'd sell it like every other 340 I've had over the years and use the money to build a 360. lol

Swinger 340

Well-Known Member

These are true for a factory build but who knows what happened afterwards. Block appears a need to be decked. All 340's had the same same casting block, just the internals were different on the low compression ones. Being it needs a total rebuild, why not buy the early parts to bring the compression up to 10.5 - 1 ? Cast or steel crank will work for most builds, unless you are using the button. $300 - $500.00 would be a fair price, without the heads.View attachment 1716029639

View attachment 1716029640

These are the factory markings for undersize engine components including crankshaft journals.

To know crank diameter, check the bearing markings. StD, +0.010, etc. But I would go with a new complete rotating assembly from a US supplier. Cheap insurance, and the opportunity to select stroke. Many options there. Hard to beat ported X heads if this is what it has, but I do like the weight redeuction of Eddy or TF heads now that they are available. Many advantages to Aluminum heads and weight is the enemy (quoting Mopar Action's Ehrenberger). Even though t 360 is overall a better starting point, I am a 340 person for 54 years. Got my first 340 (and still hae it) in 1969. Raced the snot out of it in SoCal for years and never broke a thing. Ran 13.40's @ 105.38 all the time in stock form. Out pulled a brand new 440+6 Cuda at top end at Irwindale in 1970. That surprised him. He thought I had a Hemi! Jaw dropping moment when he saw the 340.

1sttvbn

Active Member

I’ve seen a cast February’72 built 340The compression drop and cast crank came in some time around April of 1972, so it's entirely possible it's a forged crank, 10.2:1 motor.

justinp61

Well-Known Member

- Joined

- May 15, 2009

- Messages

- 3,146

- Reaction score

- 4,149

Who in the US is making and selling "cheap" cranks and rods?To know crank diameter, check the bearing markings. StD, +0.010, etc. But I would go with a new complete rotating assembly from a US supplier. Cheap insurance, and the opportunity to select stroke. Many options there. Hard to beat ported X heads if this is what it has, but I do like the weight redeuction of Eddy or TF heads now that they are available. Many advantages to Aluminum heads and weight is the enemy (quoting Mopar Action's Ehrenberger). Even though t 360 is overall a better starting point, I am a 340 person for 54 years. Got my first 340 (and still hae it) in 1969. Raced the snot out of it in SoCal for years and never broke a thing. Ran 13.40's @ 105.38 all the time in stock form. Out pulled a brand new 440+6 Cuda at top end at Irwindale in 1970. That surprised him. He thought I had a Hemi! Jaw dropping moment when he saw the 340.

There is nothing wrong with factory 340 cranks, there have been many built that ran hard with either cast or forged cranks. Yes, I'd prefer forged, but for 90% of the street builds the cast crank will work fine.

Last edited:

abodyjoe

Well-Known Member

To know crank diameter, check the bearing markings. StD, +0.010, etc. But I would go with a new complete rotating assembly from a US supplier. Cheap insurance, and the opportunity to select stroke. Many options there. Hard to beat ported X heads if this is what it has, but I do like the weight redeuction of Eddy or TF heads now that they are available. Many advantages to Aluminum heads and weight is the enemy (quoting Mopar Action's Ehrenberger). Even though t 360 is overall a better starting point, I am a 340 person for 54 years. Got my first 340 (and still hae it) in 1969. Raced the snot out of it in SoCal for years and never broke a thing. Ran 13.40's @ 105.38 all the time in stock form. Out pulled a brand new 440+6 Cuda at top end at Irwindale in 1970. That surprised him. He thought I had a Hemi! Jaw dropping moment when he saw the 340.

not interested in stroker kits, not interested in ported heads and not interested in alumn heads.

Guy from my town bought a brand new 1969 340 cuda- s notch a56 i thnk is the twin scoops

bracket raced it for 25 years before having a stroke 10 plus trophies in his basement i bought a 4.56 pumpkin from him 1985 he woudnt sell the 4.30s

he said ive tried every combo over 20 years cams gears intakes carbs he settled on

stock cam advanced

tarantula intake

700 dp

3.55s

stock exhaust car was quiet as a mouse

10 inch wide street 50s

snubber

not even a shift kit

13.1 dial in

13.1 104 105 over and over again

sometimes less is more

shows how much a good carb helps a 340 and a good tune 13.1 pretty much stock through exhaust manifolds hard to argue with dps rule

everyone seems to hate the tarantula and the torker

I liked my torker 340 with spray drove fine without it still have it sentimental reasons atleast

bracket raced it for 25 years before having a stroke 10 plus trophies in his basement i bought a 4.56 pumpkin from him 1985 he woudnt sell the 4.30s

he said ive tried every combo over 20 years cams gears intakes carbs he settled on

stock cam advanced

tarantula intake

700 dp

3.55s

stock exhaust car was quiet as a mouse

10 inch wide street 50s

snubber

not even a shift kit

13.1 dial in

13.1 104 105 over and over again

sometimes less is more

shows how much a good carb helps a 340 and a good tune 13.1 pretty much stock through exhaust manifolds hard to argue with dps rule

everyone seems to hate the tarantula and the torker

I liked my torker 340 with spray drove fine without it still have it sentimental reasons atleast

The last crank I had re-ground was $125, but that was in 2019Yeah but... you're gonna spend $300-400 getting that crank reground. If it were me, id try to just get the block and buy an aftermarket forging 4" stroke. Would cost a bit more initially but you'd be happy with the torque. But that's me.

Dartswinger70

Well-Known Member

Are the Pistons on the low comp 340 down in the hole like a 318?

I don't think so but will measure mine when I put it back together this winter.

I recently had it quoted a couple places nearby me for my 360, and they were quoting $350. Prices have gone up a whole bunch in the last few years.The last crank I had re-ground was $125, but that was in 2019

Rat Bastid

Dunamis Metron

Are the Pistons on the low comp 340 down in the hole like a 318?

Yes. They moved the pin up in the piston to move the piston down the hole to kill compression.

Dartswinger70

Well-Known Member

Do you mean standard never run or standard with light wear and can be bored .010, .020. .030, .040 etc. I am actually right now assembling my "spare" 340 I had sitting around in pieces for years. amazingly the block has cleaned up nice. I had greased the bores years ago.Standard bore 340 block is hard to find. If it is easy 1000 just for the block around here.

-