i have a 408 magnum and want to check valve lash.it has comp magnum roller rockers.its a running engine.do i hand turn crank until its on the base of the cam and tighten while turning pushrods until i feel a slight resistance? then tighten another 1/4-1/2 or full turn?its a hyd.roller cam.i know the stock rockers u just torqued to 21 ft lbs,but i am not sure with the comp.adjustable roller rockers.please advise on the procedure.thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

360 magnum ROLLER ROCKER valve LASH question

- Thread starter jdsduster

- Start date

-

72Dart6pack

Harder Better Faster Stronger.

What type of lifters are you using? Is the first question?

What type of lifters are you using? Is the first question?

mp hyd.roller

72Dart6pack

Harder Better Faster Stronger.

I'll let other people chime in on this. Now that people know what you are doing. Don't wanna tell you something wrong & nine disagree flags get thrown on the subject. Don't worry you will get a answer.

they are comp pro magnums on magnum eddy heads.hughes engines say adjust until resistance is felt with fingers,then tighten 2 turns and lock down.i just want to be sure this is the correct procedure

72Dart6pack

Harder Better Faster Stronger.

Yes it is. I have the same setup. But someone is bound to throw a red flag. Write a 500 word essay on the topic. And said you should have used the parts they suggested.

69_340_GTS

Well-Known Member

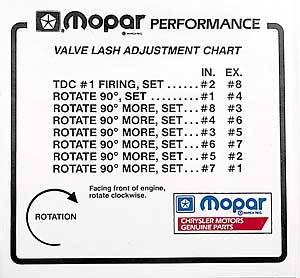

All I can add is doing it per Mopar's chart has never failed me. No guessing where the base circle of the cam is if you do it per the chart.

39[/ATTACH][/QUOTEAll I can add is doing it per Mopar's chart has never failed me. No guessing where the base circle of the cam is if you do it per the chart.

View attachment 1715081739

thanks

This is worth learning a lot more about. Different brands of lifters react differently to the oil used from what I have read. Dyno sessions have shown definate horsepower changes due to different combinations of oil types and lifters from time to time.

On the Mopar 90 degree chart, moderate spring pressure motors will be just fine anywhere close to the 90 degree Mark, say about 15 degrees either side no matter how much duration the cam has. High pressure springs, like 300+ seat and 900 over the nose show up to .003 Lash change due to cam flex, if you are early by 10 degrees versus late by 10 or 15 degrees from the 90 degree mark. The variance is caused by adjoining lobes under pressure.

On the Mopar 90 degree chart, moderate spring pressure motors will be just fine anywhere close to the 90 degree Mark, say about 15 degrees either side no matter how much duration the cam has. High pressure springs, like 300+ seat and 900 over the nose show up to .003 Lash change due to cam flex, if you are early by 10 degrees versus late by 10 or 15 degrees from the 90 degree mark. The variance is caused by adjoining lobes under pressure.

Last edited:

they are comp pro magnums on magnum eddy heads.hughes engines say adjust until resistance is felt with fingers,then tighten 2 turns and lock down.i just want to be sure this is the correct procedure

Why don't you beleave Hughes instructions? As stated, oil viscosity and cleanlyness can and will have an affect on lifter operation; that said, Hughes is giving you a known starting point; you can move from this setting in SMALL increments, tighter/looser gauge how well the engine runs, it's called tuning the combination.

mderoy340

Well-Known Member

I ran mine at 1/2 turn, Lunati 234@050 hyd roller, OEM lifters. Hughes wants 2 turns because it's quiter (people complain about noise) and the OEM Magnum preload is around .060 - .080

When I set preload I use the up and down method to get to zero lash, and then go 1/2 turn. The MP chart worked for me also. Once you are set at 1/2 turn you can also mark the adjusters with a paint dot. If you want to add additional preload you have a reference point.

When I set preload I use the up and down method to get to zero lash, and then go 1/2 turn. The MP chart worked for me also. Once you are set at 1/2 turn you can also mark the adjusters with a paint dot. If you want to add additional preload you have a reference point.

If you are using the Mopar Performance hydraulic roller lifter P5249862 then 1 turn of preload with the Comp Cams Pro Magnum rocker arms should be sufficient.because comp says 1/2 turn more at 0 lash and hughes says 2 more at 0 lash.thats why i was asking

If you are using the Mopar Performance hydraulic roller lifter P5249862 then 1 turn of preload with the Comp Cams Pro Magnum rocker arms should be sufficient.

yes i am.thanks,i was hoping you would chime in

rklein383

Well-Known Member

- Joined

- Dec 2, 2005

- Messages

- 2,216

- Reaction score

- 1,816

I am having the same questions, so thanks for the input. Hughes says around .080 preload which would equate to nearly two full turns with a 24 threads per inch rocker stud. One full turn equals .042 inch preload. I think the full two turns would be quieter, so maybe that is why Hughes recommends it. Rod

bdusted440

Well-Known Member

I set mine at 1 turn past 0 lash. No issues.

rklein383

Well-Known Member

- Joined

- Dec 2, 2005

- Messages

- 2,216

- Reaction score

- 1,816

I am leaning towards one full turn. I have to determine what pushrod length to buy, so I need to know how much extra I need to add to my pushrod length after verifying my rockers are contacting the valve stem correctly.

-