Hi!

I'm new to this forum, and start with a small block engine question.

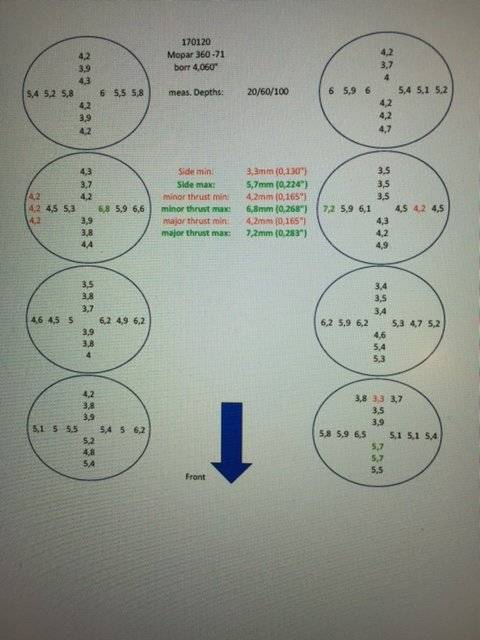

I'm building a 4" stroke LA 360 (408).

Unfortunately, the -71 360 block I managed to find here in Sweden was quite rusty.

It had to be bored to 4.060" to clear up.

I have read all about the early 360 having extra thick cylinder walls, but also that it all might be a myth.

The general advise people always get is to have the block sonic tested regardless of what year the casting is.

So... I did that, and got the numbers, but what is really considered safe?

See the attached picture ( I hope it's possible to read)

Minimum major thrust wall thickness is 0.165"

What do you experts say? Good or bad for a 408 stroker (actually 413) with aftermarket heads, about 10:1 compression, flat tappet cam, RPM dual plane intake... I aim for close to 500 hp.

/Magnus

I'm new to this forum, and start with a small block engine question.

I'm building a 4" stroke LA 360 (408).

Unfortunately, the -71 360 block I managed to find here in Sweden was quite rusty.

It had to be bored to 4.060" to clear up.

I have read all about the early 360 having extra thick cylinder walls, but also that it all might be a myth.

The general advise people always get is to have the block sonic tested regardless of what year the casting is.

So... I did that, and got the numbers, but what is really considered safe?

See the attached picture ( I hope it's possible to read)

Minimum major thrust wall thickness is 0.165"

What do you experts say? Good or bad for a 408 stroker (actually 413) with aftermarket heads, about 10:1 compression, flat tappet cam, RPM dual plane intake... I aim for close to 500 hp.

/Magnus