You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

383 power upgrade help

- Thread starter Joey N

- Start date

-

Joey N

Well-Known Member

Contact @MOPAROFFICIAL for head work or help, he's in your area.

You already have close chambered heads use them. About the only thing they need is mild port job and a bigger exhaust valve. In the picture it looks like they have the 1.5 or is it 1.60 exhaust valve but I could be wrong.

It looks like you could clean up that bore with a hone job, put a fresh set of rings and bearings in it and that short block would be good to go.

Throw in about a 480 lift purple shaft for a cam. You already have the intake. Stick a 750 or 780 Holley vacuum secondary carburetor on it. Or a 4779 holley 750 but your mileage will drop.

Stick it down in that a body with a set of b-body headers for a 383 and drive or cruise across America with it after you make sure you have a good transmission.

FYI you can use B-body headers in an A body with a 383 but you cannot use them with a 440. The reason being the 440 is an RB block which puts the heads farther out toward the fenders. Which makes the tubes hit things.

You already have close chambered heads use them. About the only thing they need is mild port job and a bigger exhaust valve. In the picture it looks like they have the 1.5 or is it 1.60 exhaust valve but I could be wrong.

It looks like you could clean up that bore with a hone job, put a fresh set of rings and bearings in it and that short block would be good to go.

Throw in about a 480 lift purple shaft for a cam. You already have the intake. Stick a 750 or 780 Holley vacuum secondary carburetor on it. Or a 4779 holley 750 but your mileage will drop.

Stick it down in that a body with a set of b-body headers for a 383 and drive or cruise across America with it after you make sure you have a good transmission.

FYI you can use B-body headers in an A body with a 383 but you cannot use them with a 440. The reason being the 440 is an RB block which puts the heads farther out toward the fenders. Which makes the tubes hit things.

Last edited:

Joey N

Well-Known Member

Contact @MOPAROFFICIAL for head work or help, he's in your area.

You already have close chambered heads use them. About the only thing they need is mild port job and a bigger exhaust valve. In the picture it looks like they have the 1.5 or is it 1.60 exhaust valve but I could be wrong.

It looks like you could clean up that bore with a hone job, put a fresh set of rings and bearings in it and that short block would be good to go.

Throw in about a 480 lift purple shaft for a cam. You already have the intake. Stick a 750 or 780 Holley vacuum secondary carburetor on it. Or a 4779 holley 750 but your mileage will drop.

Stick it down in that a body with a set of b-body headers for a 383 and drive or cruise across America with it after you make sure you have a good transmission.

FYI you can use B-body headers in an A body with a 383 but you cannot use them with a 440. The reason being the 440 is an RB block which puts the heads farther out toward the fenders. Which makes the tubes hit things.

Okay thank you this really does help I’ll see about getting it honed I just wish I knew the compression ratio I’ll figure it out someday I guess maybe I’ll get it all together and then get it checked I’ll be doing what you saidContact @MOPAROFFICIAL for head work or help, he's in your area.

You already have close chambered heads use them. About the only thing they need is mild port job and a bigger exhaust valve. In the picture it looks like they have the 1.5 or is it 1.60 exhaust valve but I could be wrong.

It looks like you could clean up that bore with a hone job, put a fresh set of rings and bearings in it and that short block would be good to go.

Throw in about a 480 lift purple shaft for a cam. You already have the intake. Stick a 750 or 780 Holley vacuum secondary carburetor on it. Or a 4779 holley 750 but your mileage will drop.

Stick it down in that a body with a set of b-body headers for a 383 and drive or cruise across America with it after you make sure you have a good transmission.

FYI you can use B-body headers in an A body with a 383 but you cannot use them with a 440. The reason being the 440 is an RB block which puts the heads farther out toward the fenders. Which makes the tubes hit things.

Joey N

Well-Known Member

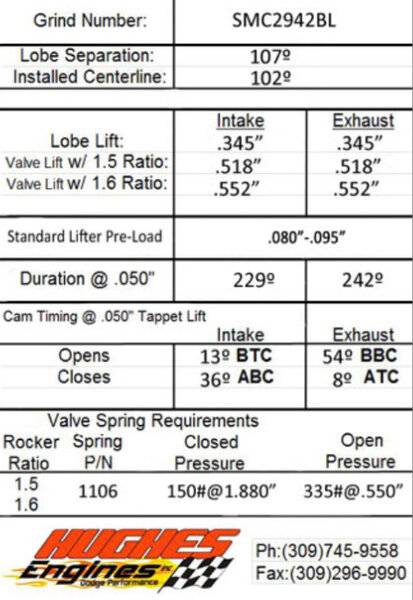

Does anyone know what the lift is on the Hughes whiplash I can’t get a clear answer and I don’t understand the spec sheet it gives you I’ll post a picture is it too much for my motor?

Lobe lift .518 those are made for low compression engines. That would be a great cam for the stock headsDoes anyone know what the lift is on the Hughes whiplash I can’t get a clear answer and I don’t understand the spec sheet it gives you I’ll post a picture is it too much for my motor?

View attachment 1716202474

View attachment 1716202475

Joey N

Well-Known Member

Okay I think I’ll just get that kit then and does anyone know any good rocker arm shaft and assembly I should replace the old one with I just want to be safe since it wasn’t tightened down it might be bent

Take everything off the rocker arm shaft clean it up, and then roll it across the table top and see if it's bent.Okay I think I’ll just get that kit then and does anyone know any good rocker arm shaft and assembly I should replace the old one with I just want to be safe since it wasn’t tightened down it might be bent

I would not just go throwing money at parts. I would make a list of what I think I need or do need and study the list before I go buying anything.

Starting your list should be a new oil pump, a timing chain and gear set, and a gasket set.

If you spray some Degreaser or something on the top of those pistons and wipe them off you may find the part number and the oversized stamp on them. The part number may be on the bottom of the piston also.

Then we can look up the part number and tell you pretty much what compression ratio you have using those close chamber heads.

If you want to check for the top dead center measurement put the harmonic balancer bolt back in the crankshaft and take a socket and breaker bar and crank the motor over to where a Piston is at the top of the cylinder. It doesn't matter which cylinder just any cylinder.

Last edited:

Joey N

Well-Known Member

Wow!

I can’t believe I didn’t think of something that simple hahaTake everything off the rocker arm shaft clean it up, and then roll it across the table top and see if it's bent.

Joey N

Well-Known Member

should I get new springs or is whatever is on there will be fine

What cam did it have on it? The Whiplash cam uses a 1.88 install height on the valve. Your Springs and retainers I'm sure are not that tall. So it would depend on which cam you wind up with what Springs and retainers you would need and valve stem seals would be needed also.should I get new springs or is whatever is on there will be fine

The Whiplash would be a great cam for your 383.should I get new springs or is whatever is on there will be fine

I suggest getting the whole 9 yards cam, lifters and matching springs.

Do what is recommended by hughesshould I get new springs or is whatever is on there will be fine

Man, yall are just makin this SO dang hard when it does't have to be. Just build up a stone stock blueprinted 383HP engine and call it a day. Blueprinted = what the factory did NOT do. That includes decking the block to the factory spec and making it squared with the crank centerline. Have the crank ground and indexed. That means every crank throw is exactly the same. Get the heads milled so the chambers are all the same size. Use a set of the Speed Pro HP pistons so they come up in the bore good and tall at TDC. Use the STOCK spec Road Runner cam. Get a distributor with a good, loose advance curve. Bolt on an Edelbrock RPM intake, Quick Fuel 750 mechanical secondary (double pumper) and a set of headers. The stock factory torque rating on the 383HP is 425 LB FT. That's FOUR HUNDRED TWENTY FIVE POUND FEET. With the above machining techniques and added bolt ons with the good ignition curve, you will be all over 500 LB FT from a basically stock 383, with GREAT street manners and vacuum out the BUTT to run power brakes. WHY do it any other way?

Contact @MOPAROFFICIAL for head work or help, he's in your area.

You already have close chambered heads use them. About the only thing they need is mild port job and a bigger exhaust valve. In the picture it looks like they have the 1.5 or is it 1.60 exhaust valve but I could be wrong.

It looks like you could clean up that bore with a hone job, put a fresh set of rings and bearings in it and that short block would be good to go.

Throw in about a 480 lift purple shaft for a cam. You already have the intake. Stick a 750 or 780 Holley vacuum secondary carburetor on it. Or a 4779 holley 750 but your mileage will drop.

Stick it down in that a body with a set of b-body headers for a 383 and drive or cruise across America with it after you make sure you have a good transmission.

FYI you can use B-body headers in an A body with a 383 but you cannot use them with a 440. The reason being the 440 is an RB block which puts the heads farther out toward the fenders. Which makes the tubes hit things.

Take everything off the rocker arm shaft clean it up, and then roll it across the table top and see if it's bent.

I would not just go throwing money at parts. I would make a list of what I think I need or do need and study the list before I go buying anything.

Starting your list should be a new oil pump, a timing chain and gear set, and a gasket set.

If you spray some Degreaser or something on the top of those pistons and wipe them off you may find the part number and the oversized stamp on them. The part number may be on the bottom of the piston also.

Then we can look up the part number and tell you pretty much what compression ratio you have using those close chamber heads.

If you want to check for the top dead center measurement put the harmonic balancer bolt back in the crankshaft and take a socket and breaker bar and crank the motor over to where a Piston is at the top of the cylinder. It doesn't matter which cylinder just any cylinder.

perfect advice for a 17 year old on a budget.

perfect advice for a 17 year old on a budget.This was my second build. A re-ringed 68 383 build was my first with a 15 year old's budget.Man, yall are just makin this SO dang hard when it does't have to be. Just build up a stone stock blueprinted 383HP engine and call it a day. Blueprinted = what the factory did NOT do. That includes decking the block to the factory spec and making it squared with the crank centerline. Have the crank ground and indexed. That means every crank throw is exactly the same. Get the heads milled so the chambers are all the same size. Use a set of the Speed Pro HP pistons so they come up in the bore good and tall at TDC. Use the STOCK spec Road Runner cam. Get a distributor with a good, loose advance curve. Bolt on an Edelbrock RPM intake, Quick Fuel 750 mechanical secondary (double pumper) and a set of headers. The stock factory torque rating on the 383HP is 425 LB FT. That's FOUR HUNDRED TWENTY FIVE POUND FEET. With the above machining techniques and added bolt ons with the good ignition curve, you will be all over 500 LB FT from a basically stock 383, with GREAT street manners and vacuum out the BUTT to run power brakes. WHY do it any other way?

That 400 you built was pretty nice.Man, yall are just makin this SO dang hard when it does't have to be. Just build up a stone stock blueprinted 383HP engine and call it a day. Blueprinted = what the factory did NOT do. That includes decking the block to the factory spec and making it squared with the crank centerline. Have the crank ground and indexed. That means every crank throw is exactly the same. Get the heads milled so the chambers are all the same size. Use a set of the Speed Pro HP pistons so they come up in the bore good and tall at TDC. Use the STOCK spec Road Runner cam. Get a distributor with a good, loose advance curve. Bolt on an Edelbrock RPM intake, Quick Fuel 750 mechanical secondary (double pumper) and a set of headers. The stock factory torque rating on the 383HP is 425 LB FT. That's FOUR HUNDRED TWENTY FIVE POUND FEET. With the above machining techniques and added bolt ons with the good ignition curve, you will be all over 500 LB FT from a basically stock 383, with GREAT street manners and vacuum out the BUTT to run power brakes. WHY do it any other way?

Take a look at Rustyratrods 400 build, you can follow it for your 383 build.Hello to everyone that sees this! I have a 383 out of a 67 newport bored .30 over flat top pistons with 516 heads I believe they are untouched but I don't know for sure , I am looking for advice on what kind of heads I should get I want to go aluminum but I need to here everyone's opinions and what they think is best this will be going into a 73 Duster paired with a OD 4 speed I don't need a lot of power but enough to have fun and sound good It will be daily driven to school and back so not too much. Id also like to know if anyone can suggest a good cam I here all kinds of mixed opinions on comp cams vs Hughes but I wanted to go with Hughes whiplash cam if possible. Thank you for all of your time and patience im fairly new to this I am also only 17

@Stephen Hotz is gonna find out. Cause like a lot of nice things I've had through the years, I had to let go of something. I do hope to build a 383 one day not too far off just like I outlined above.That 400 you built was pretty nice.

MOPAROFFICIAL

Oogliboogli

Check the in a called height on the springs and then remove and test them at inst height and then desired cam lift, as well as coil bind clearance.

The pistons look like 9.2-1 silvolites or something else, down in the hole .020 or so...? Either way, they'll work.

Flat tappet Cam in the 225-235 @.050 ..277-282adv

Something narrow to build cylinder psi is what I'd go with.

If the bores are good.. leave the bottom end alone. If they're re rung revisited ... them bore n hone, new pistons, start over.

Definitely up the exhaust valve, mild porting maybe, good valve job for sure.

De burr the chamber edges.

Flip the motor.and with each positioned at tdc.. scrape the crap off.

Just a thought

The pistons look like 9.2-1 silvolites or something else, down in the hole .020 or so...? Either way, they'll work.

Flat tappet Cam in the 225-235 @.050 ..277-282adv

Something narrow to build cylinder psi is what I'd go with.

If the bores are good.. leave the bottom end alone. If they're re rung revisited ... them bore n hone, new pistons, start over.

Definitely up the exhaust valve, mild porting maybe, good valve job for sure.

De burr the chamber edges.

Flip the motor.and with each positioned at tdc.. scrape the crap off.

Just a thought

I hope he looks you up, if you're willing to help a kid out and maybe go a little light on his wallet. just a littleCheck the in a called height on the springs and then remove and test them at inst height and then desired cam lift, as well as coil bind clearance.

The pistons look like 9.2-1 silvolites or something else, down in the hole .020 or so...? Either way, they'll work.

Flat tappet Cam in the 225-235 @.050 ..277-282adv

Something narrow to build cylinder psi is what I'd go with.

If the bores are good.. leave the bottom end alone. If they're re rung revisited ... them bore n hone, new pistons, start over.

Definitely up the exhaust valve, mild porting maybe, good valve job for sure.

De burr the chamber edges.

Flip the motor.and with each positioned at tdc.. scrape the crap off.

Just a thought

I think you'd do him right and fix him up.

My thoughts on the cylinder bores were the fact that it's already 30 over it might just need honed an new rings. I did not notice a ridge in the picture he posted of the Pistons in the bores. So why spendCheck the in a called height on the springs and then remove and test them at inst height and then desired cam lift, as well as coil bind clearance.

The pistons look like 9.2-1 silvolites or something else, down in the hole .020 or so...? Either way, they'll work.

Flat tappet Cam in the 225-235 @.050 ..277-282adv

Something narrow to build cylinder psi is what I'd go with.

If the bores are good.. leave the bottom end alone. If they're re rung revisited ... them bore n hone, new pistons, start over.

Definitely up the exhaust valve, mild porting maybe, good valve job for sure.

De burr the chamber edges.

Flip the motor.and with each positioned at tdc.. scrape the crap off.

Just a thought

the money on unneeded machine work?

He needs somebody to check the block over before putting a bunch of money into it.

I'm thinking the kid is not a millionaire an might be counting his pennies or nickels and dimes. I may be wrong. Are you a rich kid?

I'm thinking without buying cylinder heads and doing $1,000 of machine work he's still going to have $1500- $2,000 in this motor building it.

As for building it like a 383 HP that's a nice idea. But realize this is an earlier motor with closed chamber heads not a 68 or newer with the Pistons popping up out of the cylinders and the open chamber heads.

The interesting fact about the torque on those 383s rrr keeps mentioning is that the earlier 383s had even more torque than 425 some of them I think went to about 460.

Last edited:

Joey N

Well-Known Member

I believe it was to be comp cams nostalgia cam kit it was I think .509 liftWhat cam did it have on it? The Whiplash cam uses a 1.88 install height on the valve. Your Springs and retainers I'm sure are not that tall. So it would depend on which cam you wind up with what Springs and retainers you would need and valve stem seals would be needed also.

Joey N

Well-Known Member

I am certainly no rich kid I bought the engine for $700 since then been working every few days after school in a grocery store for this build it’s honestly one of the only things I look forwards to every day is thinking about getting it in the car lol. I’ll get better pictures of the cylinders and the piston tops I’ll clean off so we can see the stamping clearlyMy thoughts on the cylinder bores were the fact that it's already 30 over it might just need honed an new rings. I did not notice a ridge in the picture he posted of the Pistons in the bores. So why spend

the money on unneeded machine work?

He needs somebody to check the block over before putting a bunch of money into it.

I'm thinking the kid is not a millionaire an might be counting his pennies or nickels and dimes. I may be wrong. Are you a rich kid?

I'm thinking without buying cylinder heads and doing $1,000 of machine work he's still going to have $1500- $2,000 in this motor building it.

As for building it like a 383 HP that's a nice idea. But realize this is an earlier motor with closed chamber heads not a 68 or newer with the Pistons popping up out of the cylinders and the open chamber heads.

The interesting fact about the torque on those 383s rrr keeps mentioning is that the earlier 383s had even more torque than 425 some of them I think went to about 460.

Joey N

Well-Known Member

Thank you for your support I’ll get the numbers to the pistons and scrape the carbon off the top of emCheck the in a called height on the springs and then remove and test them at inst height and then desired cam lift, as well as coil bind clearance.

The pistons look like 9.2-1 silvolites or something else, down in the hole .020 or so...? Either way, they'll work.

Flat tappet Cam in the 225-235 @.050 ..277-282adv

Something narrow to build cylinder psi is what I'd go with.

If the bores are good.. leave the bottom end alone. If they're re rung revisited ... them bore n hone, new pistons, start over.

Definitely up the exhaust valve, mild porting maybe, good valve job for sure.

De burr the chamber edges.

Flip the motor.and with each positioned at tdc.. scrape the crap off.

Just a thought

-