moper

Well-Known Member

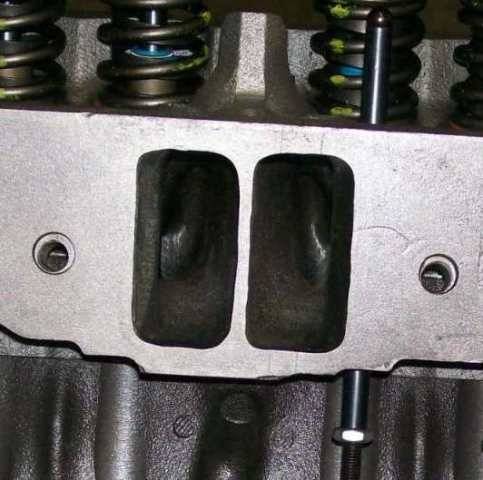

IMO, $600 isnt enough to get them "right". It is enough to make them "better". So do what the budget allows, but understand what the consequences of that are. As I said, for me, I don't want to touch heads again but this is just my line of thinking. Because just the "take off and clean" at a later point is the same cost of the upgrades now. If you want to run a modern cam, most require dual springs (Lunati Voo Doos all have a dual assembly recommended). So springs and retainers have to be bought anyway... The costs between single and dual isnt much compared to buying them twice and the retainers are the same money. But to disassemble and have them cut, then buy a second set of springs, then reassembled, will cost more than just doing it straight away. In terms of valve size... Sinking a valve is the worst you can do. And to run a used valve on a freshly cut seat sinks it. No other way to do it. Then you're stuck with even larger chambers and further reduced flow/power. Which is why I just account for new valves. All these parts work intimately together. So by not doing it the first time, you end up paying double for the result you could have had for less. You could buy stock type valves for less money. but that's about the only cost savings I see being realized. Attached is a few pics of a set of 308s on a 422 that makes about 470hp with a hydraulic .518 lift 242°@.050 cam. These heads have a little porting but not much, and they were $1400 after porting, ready to bolt on. $1120 w/o port work.