Can a 451 be built with a stock 440 forged crank, KB pistons stock rods and internally balanced with out adding heavy metal to the crank? Thank You

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

451 build

- Thread starter 92b

- Start date

-

slickchick

pedal cars only

Thanks for the link. That's a nice build. I'm looking at a low buck build using stock parts. My machinist has only done a cast 451 build and thought that it took 2 slugs of heavy metal to balance it out. That kind of breaks the budget on a stock forged crank. At that price point it might make more sense to get a new crank opening up more stroke possibilities. I really want to do this on the cheap. If I can balance with the stock components and not have to add heavy metal I think I can do it. I'm even open to external balance and a lower rpm build. Wondering if someone has first hand experience with a stock components build or has tried and couldn't balance with out heavy metal. Thank you.

Yes........as an example......Can a 451 be built with a stock 440 forged crank, KB pistons stock rods and internally balanced with out adding heavy metal to the crank? Thank You

400/450 stroker....Cheap parts, lotta work.

Last edited:

I'll give it a read. Thank you

In deference to the Ray Barton build in post #2, we turned our 440 forged crank down to 400 mains on another 451 build and used it to make 606 lb-ft of torque and then 787 horsepower on 91 octane pump gas. So I'm thinkin' you don't need to bore the 400 block out to 440 mains. But.......I don't see a problem with doin' it that way.

What do you recommend for counterweight diameter ? 7.150 or 7.250In deference to the Ray Barton build in post #2, we turned our 440 forged crank down to 400 mains on another 451 build and used it to make 606 lb-ft of torque and then 787 horsepower on 91 octane pump gas. So I'm thinkin' you don't need to bore the 400 block out to 440 mains. But.......I don't see a problem with doin' it that way.

The mains are a little beat up on this crank so it's a perfect candidate for turning down. Also why I got it for free. Do the counter weights on a forged crank need to be turned down for clearance on a stock rod build? Thank you.In deference to the Ray Barton build in post #2, we turned our 440 forged crank down to 400 mains on another 451 build and used it to make 606 lb-ft of torque and then 787 horsepower on 91 octane pump gas. So I'm thinkin' you don't need to bore the 400 block out to 440 mains. But.......I don't see a problem with doin' it that way.

I'd like to know what IQ52 has to say but if you look at most aftermarket stroker crankshafts the counterweights are at 7.150, which means yes you need to have them groundThe mains are a little beat up on this crank so it's a perfect candidate for turning down. Also why I got it for free. Do the counter weights on a forged crank need to be turned down for clearance on a stock rod build? Thank you.

I've never measured the counterweight diameter. I turn the counterweights .120" in radius on my lathe and then turn the crankshaft over to the grinder. When the crank comes back I drop it into the block and see if it fits. Sometimes I must bevel the counterweight or grind some on the block to get sufficient clearance. I grind it to clear the block not the rods. I've only used stock 400 rods or aftermarket 440 H-beam rods.What do you recommend for counterweight diameter ? 7.150 or 7.250

Do you have to add heavy metal to get it to internal balance? Thank you.

Okay thank youI've never measured the counterweight diameter. I turn the counterweights .120" in radius on my lathe and then turn the crankshaft over to the grinder. When the crank comes back I drop it into the block and see if it fits. Sometimes I must bevel the counterweight or grind some on the block to get sufficient clearance. I grind it to clear the block not the rods. I've only used stock 400 rods or aftermarket 440 H-beam rods.

I thought I had answered the question in post #4 when I answered 'yes' to your original post.Do you have to add heavy metal to get it to internal balance? Thank you.

So........more clearly..........

With factory forged 440 cranks....in my 451 builds.....never have I had to use heavy metal to internally balance the engine.

Yes, you did answer that in post 4. That should give you some indication of how long my memory is. Thank you again for clearing that up. I have one last question but forgot what it was.I thought I had answered the question in post #4 when I answered 'yes' to your original post.

So........more clearly..........

With factory forged 440 cranks....in my 451 builds.....never have I had to use heavy metal to internally balance the engine.

I used a 440 crank with a 383 block. Turned the mains on the crank down to 383 size. I also used the shorter 383 rods, as I am a believer of short rods for performance street engines. Turned down the c/weights 1/8" to reduce rotating weight. This was over 30 yrs ago, but pretty sure didn't need Mallory metal to balance it. That thing spun up real quick...

Is this the lost answer?..........Yes, you did answer that in post 4. That should give you some indication of how long my memory is. Thank you again for clearing that up. I have one last question but forgot what it was.

I machine the counterweights to clear the block, not to clear the rods.

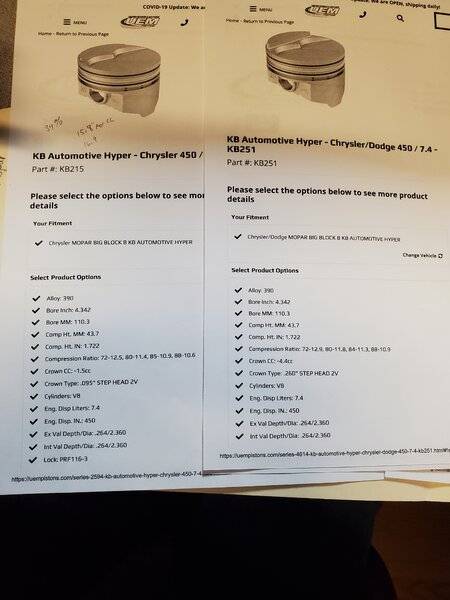

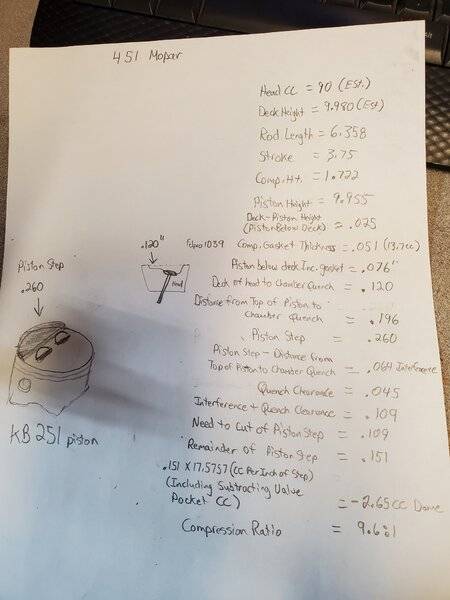

I want to run this on pump gas. I tried to estimate the compression ratio and this is what I came up with. Was hoping it would be a little lower as it will be easier to adjust the compression up a little than it will be

down. I want this to be a cheap stockish build. Anyone care to proof read my numbers? Thank you.

down. I want this to be a cheap stockish build. Anyone care to proof read my numbers? Thank you.

pishta

I know I'm right....

our 451 build had the forged crank turned down (never open the mains!) and my friend ground the counterweights by hand with a grinder! Took him a week in his garage doing one a night. He also knife edged them. The KB pistons were lighter than the stockers and IIRC we still had to remove weight from crank to balance. Stock 440 rods.

How did you come up with your 9.6:1 number ?I want to run this on pump gas. I tried to estimate the compression ratio and this is what I came up with. Was hoping it would be a little lower as it will be easier to adjust the compression up a little than it will beView attachment 1715825831 View attachment 1715825832 down. I want this to be a cheap stockish build. Anyone care to proof read my numbers? Thank you.

The one thing I see on your math is a minus where a plus should be and that is on your piston valve pockets, it should be +4.5 CC's that won't change from milling that dome down. So you would be adding volume not subtracting. That's all I see.

I am wondering what there gasket thickness is to get 10.9 with 88cc combustion chambers ?

Last edited:

I have a compression calculator on an excel spreadsheet. It adds the total volume so the dome is input as a negative number since it subtracts volume. I wish they would give all the specs they use to arrive at their number. Thanks for looking it over.How did you come up with your 9.6:1 number ?

The one thing I see on your math is a minus where a plus should be and that is on your piston valve pockets, it should be +4.5 CC's that won't change from milling that dome down. So you would be adding volume not subtracting. That's all I see.

I am wondering what there gasket thickness is to get 10.9 with 88cc combustion chambers ?

Yeah, it sounds correct. If you really wanted to you could punch in a couple different gasket thicknesses to get the #'s. Happy ThanksgivingI have a compression calculator on an excel spreadsheet. It adds the total volume so the dome is input as a negative number since it subtracts volume. I wish they would give all the specs they use to arrive at their number. Thanks for looking it over.

-