You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

505 stroker fresh off the dyno - Power seems low? Thoughs?

- Thread starter Minnesota Muscle

- Start date

-

learning

learningPRH

Well-Known Member

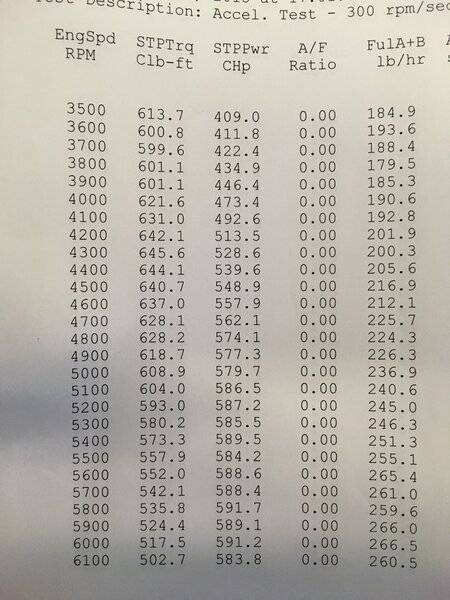

I’d be interested to know what the elevation of the dyno shop is, as well as the weather conditions for that day.

Not that those would have much impact on the corrected numbers.

However based on the fuel flow and bsfc numbers there was a fairly decent correction factor being applied.

(Looks like the uncorrected peak power would have been in the 520’s)

The bsfc numbers are pretty decent, so it’s not like the motor was using tons of fuel and not making power with it.

It just wasn’t using much fuel......... so there isn’t going to be big power being made.

The effective rocker ratio after the B3 kit installation looks like it works out to 1.435.

If the manifold isn’t ported, there is some power left on the table there.

At this point, I think the first thing is to see if you can get a cranking compression test.

If you go in with the inspection camera, see if you can get a look at the piston CH situation with the piston at tdc.

One thing that stands out to me is the peak TQ number is rather low for the sum of those parts.

So, the power starts out on the low side, and never really turns that around, so you end up with low-ish HP.

What fuel was used?

30* timing seems really low to me.

Not that those would have much impact on the corrected numbers.

However based on the fuel flow and bsfc numbers there was a fairly decent correction factor being applied.

(Looks like the uncorrected peak power would have been in the 520’s)

The bsfc numbers are pretty decent, so it’s not like the motor was using tons of fuel and not making power with it.

It just wasn’t using much fuel......... so there isn’t going to be big power being made.

The effective rocker ratio after the B3 kit installation looks like it works out to 1.435.

If the manifold isn’t ported, there is some power left on the table there.

At this point, I think the first thing is to see if you can get a cranking compression test.

If you go in with the inspection camera, see if you can get a look at the piston CH situation with the piston at tdc.

One thing that stands out to me is the peak TQ number is rather low for the sum of those parts.

So, the power starts out on the low side, and never really turns that around, so you end up with low-ish HP.

What fuel was used?

30* timing seems really low to me.

Last edited:

I think we've already established that. But thank you.rob, a .030 over , 440, with a 4.250 crank , is exactly 505 , and a hair----

my 1966 440 block only took .003 to put them at zero deck , which I thot was interesting .

PRH

Well-Known Member

Here’s a 505 build........

10.9cr

XS290S cam 1.5 rockers

STG 1 RPM heads

2-2 1/8 headers

Pump gas

6bbl

Notice it’s using quite a bit more fuel:

This pull was at 170* water temp.

A “hero pull” at 120* was made, and the results were over 650tq and 600hp.

10.9cr

XS290S cam 1.5 rockers

STG 1 RPM heads

2-2 1/8 headers

Pump gas

6bbl

Notice it’s using quite a bit more fuel:

This pull was at 170* water temp.

A “hero pull” at 120* was made, and the results were over 650tq and 600hp.

PRH

Well-Known Member

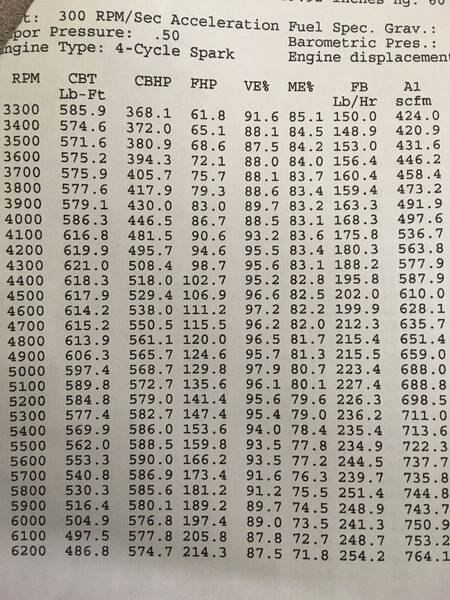

I remembered I tested a somewhat similar combo........ in 2008.

RB 512, 10-something CR, pump gas.

Prepped std port EZ heads, Holley SD manifold, HP950 carb, 252/261 roller cam.

I supplied the heads and did the dyno test, but didn’t build the motor.

Looking at this sheet now, it also leaves me thinking the peak tq output could have been a bit better.

This was a real street engine so it was tested with fairly hot water...... right up near 180*.

Another similar build to this one that used std port SR’s with mild porting and an M1 single plane....... but much more cam duration made about 75hp more than this one.

I didn’t supply the cam for this 512, although it was about right for the “application”.......... but if you were chasing the number on the dyno that would have been my first change.

You can see the VE never reaches 100%, and drops off pretty quickly as the rpm goes over 5600.

I wasn’t really a fan of the cam in that motor, but was still thinking it would break 600hp.......however it just didn’t happen.

RB 512, 10-something CR, pump gas.

Prepped std port EZ heads, Holley SD manifold, HP950 carb, 252/261 roller cam.

I supplied the heads and did the dyno test, but didn’t build the motor.

Looking at this sheet now, it also leaves me thinking the peak tq output could have been a bit better.

This was a real street engine so it was tested with fairly hot water...... right up near 180*.

Another similar build to this one that used std port SR’s with mild porting and an M1 single plane....... but much more cam duration made about 75hp more than this one.

I didn’t supply the cam for this 512, although it was about right for the “application”.......... but if you were chasing the number on the dyno that would have been my first change.

You can see the VE never reaches 100%, and drops off pretty quickly as the rpm goes over 5600.

I wasn’t really a fan of the cam in that motor, but was still thinking it would break 600hp.......however it just didn’t happen.

Last edited:

Minnesota Muscle

Well-Known Member

I’d be interested to know what the elevation of the dyno shop is, as well as the weather conditions for that day.

Not that those would have much impact on the corrected numbers.

However based on the fuel flow and bsfc numbers there was a fairly decent correction factor being applied.

(Looks like the uncorrected peak power would have been in the 520’s)

The bsfc numbers are pretty decent, so it’s not like the motor was using tons of fuel and not making power with it.

It just wasn’t using much fuel......... so there isn’t going to be big power being made.

The effective rocker ratio after the B3 kit installation looks like it works out to 1.435.

If the manifold isn’t ported, there is some power left on the table there.

At this point, I think the first thing is to see if you can get a cranking compression test.

If you go in with the inspection camera, see if you can get a look at the piston CH situation with the piston at tdc.

One thing that stands out to me is the peak TQ number is rather low for the sum of those parts.

So, the power starts out on the low side, and never really turns that around, so you end up with low-ish HP.

What fuel was used?

30* timing seems really low to me.

In the shop ambient air temp was 78deg, all I know.

Elevation is 900ft above sea level.

Premium 91 octane for fuel, (no 93 around us)

Last edited:

Ivoryk3ys78

Well-Known Member

Not that I think it would make a big difference but I see you wrote that you set the lash at .016 cold as it should be at .018 hot. With aluminum heads at operating temp will grow by about 6 thousandths. I set mine at .012 so I can get .018 on my howards solid cam and it was confirmed to be right at that hot.

So your lash was lose not tight as I have seen some say. You were running more like .022 lash. Shouldn't make a huge deal but on an already not too big of a cam for a big stroker your pulling a couple more degrees of duration away from it(about every .001 of lash it worth about .5 degree of duration.)

A cylinder pressure as has been stated a lot will really tell the compression story. You can search for Wallace racing dynamic compression calculator and that gives the estimated cranking compression value for the dynamic compression that results from your compression and when your intake valve closes and what your elevation is. So if your dynamic compressoin calculates to 8.5 and 175 and your showing 140s... .

A cold compression test with battery charger and carb wide open should do it.

So your lash was lose not tight as I have seen some say. You were running more like .022 lash. Shouldn't make a huge deal but on an already not too big of a cam for a big stroker your pulling a couple more degrees of duration away from it(about every .001 of lash it worth about .5 degree of duration.)

A cylinder pressure as has been stated a lot will really tell the compression story. You can search for Wallace racing dynamic compression calculator and that gives the estimated cranking compression value for the dynamic compression that results from your compression and when your intake valve closes and what your elevation is. So if your dynamic compressoin calculates to 8.5 and 175 and your showing 140s... .

A cold compression test with battery charger and carb wide open should do it.

PRH

Well-Known Member

In my mind, the thing that stands out the most when you consider the “overall” package in the low TQ output.

With the std port heads and manifold, along with a cam that has short seat timing ........ I’d have really expected a pretty nice TQ number.

I tested a really mild 505 a few years ago.

9.8cr, rpm heads, 232/238-112 old school hyd cam, original Torker(no mods), 1-7/8” headers, 850vs carb.

Even that combo made 628ft/lbs.

Hp was rather low because with everything that has to do with the engines ability to move air being on the “too small” side, the tq curve peaks, then drops like a rock.

With the std port heads and manifold, along with a cam that has short seat timing ........ I’d have really expected a pretty nice TQ number.

I tested a really mild 505 a few years ago.

9.8cr, rpm heads, 232/238-112 old school hyd cam, original Torker(no mods), 1-7/8” headers, 850vs carb.

Even that combo made 628ft/lbs.

Hp was rather low because with everything that has to do with the engines ability to move air being on the “too small” side, the tq curve peaks, then drops like a rock.

thesiren74

Well-Known Member

Run it on another Dyno lol.

PRH

Well-Known Member

Run it on another Dyno lol.

That may not be that crazy of an idea.

There could be some anomalies with the dyno room or exhaust system that are contributing to the low-ish output.

Plus, it would be nice if the dyno operator showed little more desire to troubleshoot the numbers a bit.

-Maybe the fuel is crap, and that’s why it wouldn’t take more timing.

-a compression test would have been nice

-maybe try a different setting on the valve lash

Unfortunately, without having a history for that dyno service, the numbers are kinda just numbers.

Have they tested any similar BBM combos that they could reference to see how your motor compared?

Was an air turbine(sensor) being used during testing?

Any other pages of data they gave you?

One that showed air flow and VE?

Last edited:

PRH

Well-Known Member

One last(?) comparison......

I built a 10:1 493 probably 18 years ago or so.

This was a “hot street” type build that was going into a 70 Coronet wagon, with AC.

Prepped RPM heads, wide lsa cam for good vacuum, SD manifold for hood clearance, new Holley 850DP carb, 2” headers.

It made around 590tq/560hp....... which was about what I was expecting from what I considered a really mild build.

Granted the heads and intake weren’t as good as what the OP is running...... but both the tq/ci and hp/ci are very close between this 493 and his 505.

Around that same time, I re-ringed a customers 446 that had trw L2355’s in it.

The top end was basically the twin to the 493 above.

I was expecting it to make 540-550hp.

After one dyno pull I knew I had missed the mark with the combo and it wasn’t going to get there.

I ended up trying quite a few things on the dyno(intakes/carbs/headers)...... and was never as close to the “big number” as I wanted to be, so I ended up taking a big swing at the cam.

It didn’t make much difference with the intake/carb/header combo that was destined for the car, but with a big carb, my dyno headers, a Victor intake and a 2” super sucker....... it did get over 560hp.

But none of that stuff was going in the car, nor would the car have worked very well with that combo.

What i should have done was gone to a slightly smaller cam, tightened the lsa up a bit........ shot for a better TQ number...... and then “iiwii”.

When you’re putting together an untested mix-n-match combo of parts....... sometimes it doesn’t work out as well as planned(and sometimes it works out better than planned).

I built a 10:1 493 probably 18 years ago or so.

This was a “hot street” type build that was going into a 70 Coronet wagon, with AC.

Prepped RPM heads, wide lsa cam for good vacuum, SD manifold for hood clearance, new Holley 850DP carb, 2” headers.

It made around 590tq/560hp....... which was about what I was expecting from what I considered a really mild build.

Granted the heads and intake weren’t as good as what the OP is running...... but both the tq/ci and hp/ci are very close between this 493 and his 505.

Around that same time, I re-ringed a customers 446 that had trw L2355’s in it.

The top end was basically the twin to the 493 above.

I was expecting it to make 540-550hp.

After one dyno pull I knew I had missed the mark with the combo and it wasn’t going to get there.

I ended up trying quite a few things on the dyno(intakes/carbs/headers)...... and was never as close to the “big number” as I wanted to be, so I ended up taking a big swing at the cam.

It didn’t make much difference with the intake/carb/header combo that was destined for the car, but with a big carb, my dyno headers, a Victor intake and a 2” super sucker....... it did get over 560hp.

But none of that stuff was going in the car, nor would the car have worked very well with that combo.

What i should have done was gone to a slightly smaller cam, tightened the lsa up a bit........ shot for a better TQ number...... and then “iiwii”.

When you’re putting together an untested mix-n-match combo of parts....... sometimes it doesn’t work out as well as planned(and sometimes it works out better than planned).

Last edited:

Minnesota Muscle

Well-Known Member

I appreciate some of the thoughts and the time it's taken to reply.

Here are some new number to chew on. It took some time to dig out an old transmission out of storage and get it all fabbed up to spin the engine over, so I apologize for the couple days of delay.

With no carb installed (no air intake resistance) the cylinder pressures were between 171 - 173 psi. This is with a moderately to slow turning of the engine. Had to use a jumper pack and two chargers to spin it fast enough to get what I felt were accurate numbers.

I spoke to 440 source, and they were adamant that I was given the correct pistons. They said they would have caught it when they went to balance them, as it wouldn't have balanced correctly, not to mention they would have noticed their in-stock product counts would have been off. He felt very strongly that the cam timing was off four degree's. He says they regularly see my combo in the 625hp range and felt by adding the four degrees of timing, I'd get it. I tore the shop apart and couldn't locate the scratch paper I wrote my notes on when I degreed the cam, the kids helped clean a bunch, I'm guess it was tossed by mistake. I do remember lining it up dot to dot, and the lift and duration were right on, but not the exact numbers. I think my next step is to do what some here have said and what 440 source said, pull the water pump and timing cover and check the cam timing and add four degrees.

But just because I went through all the hassle, here are some photos of the pistons too.

Here are some new number to chew on. It took some time to dig out an old transmission out of storage and get it all fabbed up to spin the engine over, so I apologize for the couple days of delay.

With no carb installed (no air intake resistance) the cylinder pressures were between 171 - 173 psi. This is with a moderately to slow turning of the engine. Had to use a jumper pack and two chargers to spin it fast enough to get what I felt were accurate numbers.

I spoke to 440 source, and they were adamant that I was given the correct pistons. They said they would have caught it when they went to balance them, as it wouldn't have balanced correctly, not to mention they would have noticed their in-stock product counts would have been off. He felt very strongly that the cam timing was off four degree's. He says they regularly see my combo in the 625hp range and felt by adding the four degrees of timing, I'd get it. I tore the shop apart and couldn't locate the scratch paper I wrote my notes on when I degreed the cam, the kids helped clean a bunch, I'm guess it was tossed by mistake. I do remember lining it up dot to dot, and the lift and duration were right on, but not the exact numbers. I think my next step is to do what some here have said and what 440 source said, pull the water pump and timing cover and check the cam timing and add four degrees.

But just because I went through all the hassle, here are some photos of the pistons too.

Last edited:

Minnesota Muscle

Well-Known Member

That may not be that crazy of an idea.

There could be some anomalies with the dyno room or exhaust system that are contributing to the low-ish output.

Plus, it would be nice if the dyno operator showed little more desire to troubleshoot the numbers a bit.

-Maybe the fuel is crap, and that’s why it wouldn’t take more timing.

-a compression test would have been nice

-maybe try a different setting on the valve lash

Unfortunately, without having a history for that dyno service, the numbers are kinda just numbers.

Have they tested any similar BBM combos that they could reference to see how your motor compared?

Was an air turbine(sensor) being used during testing?

Any other pages of data they gave you?

One that showed air flow and VE?

To be honest, I'm not sure there is another dyno in the state. originally I asked around on fakebook, and locally and only one business came up, with some speculation of another, but never did get contact info. I will put some feelers out again to see what I can find.

I asked about an air turbine to get air intake numbers, and I was greeted with a blank stare, so I assumed they didn't have one. We did look at a few other builds he had in his records, but nothing was close enough to really compare. He had one that was fairly close but was a roller cam engine, and it was 650hp, but a lot of the engine details were not noted, essentially just displacement and some minor details like carb size.

Yeah, a compression test with a strong cranking would have done me a world of good. I paid out the nose for professional advice and assistance and didn't get it. I won't be going back to Wheeler Dyno and Engine services in Blaine, MN again.

Ivoryk3ys78

Well-Known Member

Nice cranking compression there. It's not a low compression engine.

I hope you get it sorted out. Those are some nice flowing heads. I would think what they said seems quite reasonable 625/625 area.

I hope you get it sorted out. Those are some nice flowing heads. I would think what they said seems quite reasonable 625/625 area.

I appreciate some of the thoughts and the time it's taken to repy.

Here are some new number to chew on. It took some time to dig out an old transmission out of storage and get it all fabbed up to spin the engine over, so I apologize for the couple days of delay.

With no carb installed (no air intake resistance) the cylinder pressures were between 171 - 173 psi. This is with a moderately to slow turning of the engine. Had to use a jumper pack and two chargers to spin it fast enough to get what I felt were accurate numbers.

I spoke to 440 source, and they were adamant that I was given the correct pistons. They said they would have caught it when they went to balance them, as it wouldn't have balanced correctly, not to mention they would have noticed their in-stock product counts would have been off. He felt very strongly that the cam timing was off four degree's. He says they regularly see my combo in the 625hp range and felt by adding the four degrees of timing, I'd get it. I tore the shop apart and couldn't locate the scratch paper I wrote my notes on when I degreed the cam, the kids helped clean a bunch, I'm guess it was tossed by mistake. I do remember lining it up dot to dot, and the lift and duration were right on, but not the exact numbers. I think my next step is to do what some here have said and what 440 source said, pull the water pump and timing cover and check the cam timing and add four degrees.

But just because I went through all the hassle, here are some photos of the pistons too.

View attachment 1715790698

View attachment 1715790699

View attachment 1715790700

Good luck getting the 'missing' 50-75 hp by advancing the cam 4*.

You usually have to retard a cam [ not advance ] to gain top end hp. And I doubt retarding the cam will pick up 50+ hp.

I commented earlier in this thread that I thought the HP was about right for the combo. You might reach your goal with a more 'optimistic' dyno.

You can get into the realms of idiocy with this stuff. I know a bloke who claims installing a 1" carb spacer to a T2 intake gave a 102 HP increase........

You usually have to retard a cam [ not advance ] to gain top end hp. And I doubt retarding the cam will pick up 50+ hp.

I commented earlier in this thread that I thought the HP was about right for the combo. You might reach your goal with a more 'optimistic' dyno.

You can get into the realms of idiocy with this stuff. I know a bloke who claims installing a 1" carb spacer to a T2 intake gave a 102 HP increase........

448Scamp

Running Free

To be honest, I'm not sure there is another dyno in the state. originally I asked around on fakebook, and locally and only one business came up, with some speculation of another, but never did get contact info. I will put some feelers out again to see what I can find.

I asked about an air turbine to get air intake numbers, and I was greeted with a blank stare, so I assumed they didn't have one. We did look at a few other builds he had in his records, but nothing was close enough to really compare. He had one that was fairly close but was a roller cam engine, and it was 650hp, but a lot of the engine details were not noted, essentially just displacement and some minor details like carb size.

Yeah, a compression test with a strong cranking would have done me a world of good. I paid out the nose for professional advice and assistance and didn't get it. I won't be going back to Wheeler Dyno and Engine services in Blaine, MN again.

Just for your information, checking the lift and duration means nothing when degreeing the cam. At this point, it is evident you have no idea where the cam is timed. Dot to dot means nothing.

I’ll ask it again because it’s been asked before but I’ve never seen your answer. When you had the degree wheel and dial indicator on the engine, did you actually verify the installed intake centerline, or did you just line up the dots and send it?

PRH

Well-Known Member

The dish in the piston looks pretty shallow, so I’d say it has the correct pistons in it.

It’s worth verifying the cam timing is correct, but 4deg off(on the degree wheel) isn’t going to yield 50hp.

But if the cam is retarded I could see that correcting it should bring the tq numbers up closer to what I’d expect.

The cranking pressure is in that zone where it’s hard to tell if it’s good or bad(it’s obviously not “way off”).

I don’t know if this was brought up or not, but which spring package did you get on your heads?

(That would only affect the upper end of the curve)

It’s surprising that shop has an expensive dyno....... and no air turbine? Crazy.

What are the intentions for the motor?

Street car? Bracket race car?

If the power doesn’t improve....... does it really matter?

If you haven’t read thru this one yet, it’s a good read:

Degreeing a Cam, or not.....

It’s worth verifying the cam timing is correct, but 4deg off(on the degree wheel) isn’t going to yield 50hp.

But if the cam is retarded I could see that correcting it should bring the tq numbers up closer to what I’d expect.

The cranking pressure is in that zone where it’s hard to tell if it’s good or bad(it’s obviously not “way off”).

I don’t know if this was brought up or not, but which spring package did you get on your heads?

(That would only affect the upper end of the curve)

It’s surprising that shop has an expensive dyno....... and no air turbine? Crazy.

What are the intentions for the motor?

Street car? Bracket race car?

If the power doesn’t improve....... does it really matter?

If you haven’t read thru this one yet, it’s a good read:

Degreeing a Cam, or not.....

Last edited:

B3422w5

Well-Known Member

Good luck getting the 'missing' 50-75 hp by advancing the cam 4*.

You usually have to retard a cam [ not advance ] to gain top end hp. And I doubt retarding the cam will pick up 50+ hp.

I commented earlier in this thread that I thought the HP was about right for the combo. You might reach your goal with a more 'optimistic' dyno.

You can get into the realms of idiocy with this stuff. I know a bloke who claims installing a 1" carb spacer to a T2 intake gave a 102 HP increase........

Agree with you. I dont think the numbers are out of line.

Port the intake and step up the cam to something in the low 260’s, bet the motor would easily peak over 600.

Pretty tiny cam for a 500+ inch motor, imo.

PRH

Well-Known Member

Well, it appears they do have an air sensor.

Not sure why it wouldn’t have been used for the OP’s session.

Not sure why it wouldn’t have been used for the OP’s session.

PRH

Well-Known Member

Here’s another one that seemed to come up a little short:

440 Chrysler Dyno Test: Trick Flow Heads & Intake

440 Chrysler Dyno Test: Trick Flow Heads & Intake

Minnesota Muscle

Well-Known Member

The dish in the piston looks pretty shallow, so I’d say it has the correct pistons in it.

It’s worth verifying the cam timing is correct, but 4deg off(on the degree wheel) isn’t going to yield 50hp.

But if the cam is retarded I could see that correcting it should bring the tq numbers up closer to what I’d expect.

The cranking pressure is in that zone where it’s hard to tell if it’s good or bad(it’s obviously not “way off”).

I don’t know if this was brought up or not, but which spring package did you get on your heads?

(That would only affect the upper end of the curve)

It’s surprising that shop has an expensive dyno....... and no air turbine? Crazy.

What are the intentions for the motor?

Street car? Bracket race car?

If the power doesn’t improve....... does it really matter?

If you haven’t read thru this one yet, it’s a good read:

Degreeing a Cam, or not.....

The springs are TFS-16893. Installed pressure of 120lbs at 1.875, and open pressure of 394lbs at 1.175. These are the springs that trick flow sends with their flat tappet 240 heads. I spoke to Howard's cams yesterday to pick their brains about things, and he was a little concerned about the spring pressure. He said he generally doesn't like to see more than 360-370.

Anyway, he recommended getting the cranking pressure up in the 185 region, moving in two degree incriments until it gets there. I'll be ordering the stall converter today, then get that in and get the engine dropped in quick. At that point I'll pull the timing cover and check/adjust the cam timing so I can crank it over.

I plan on 30% street and 70% bracket with the car. Just taking the kids to school, a few local car shows and such.

PRH

Well-Known Member

You’re getting a lot of info, some of it conflicting, from several sources....... so I’m just going throw a few things out there...... and hopefully not add too much noise to the conversation.

Those springs are a PAC-1903.

I just had a set of those TF240 heads here to look over. They had that spring package and they were set up right at 1.900” installed height.......115 on the seat.

The spring rate is 391lb/in.

Your gross lift you stated as .575” lift...... minus lash puts you at roughly .560” net lift at the valve.

391 x .560 = 219lbs, plus the 115 on the seat = 334lbs open.

Imo, nowhere near enough for a BB bracket race engine with a fast rate cam.

My guess is, Hughes sells more cams ground using that family of lobes from Howard’s than anyone.

Look at the spring specs they suggest for a BB using those cams.

Also, look at the specs for the springs Howard’s recommends(98632) for those lobes in a BB.

Calculate the open load at full lift for that spring if you were running the 720162-08 cam(I’ll give you a hint...... it’s a fair amount higher than 360-370).

The low-ish spring load isn’t a problem(rpm wise)....... until it is.

Was that contributing to the early power peak of your engine?

Hard to say.

Those springs are a PAC-1903.

I just had a set of those TF240 heads here to look over. They had that spring package and they were set up right at 1.900” installed height.......115 on the seat.

The spring rate is 391lb/in.

Your gross lift you stated as .575” lift...... minus lash puts you at roughly .560” net lift at the valve.

391 x .560 = 219lbs, plus the 115 on the seat = 334lbs open.

Imo, nowhere near enough for a BB bracket race engine with a fast rate cam.

My guess is, Hughes sells more cams ground using that family of lobes from Howard’s than anyone.

Look at the spring specs they suggest for a BB using those cams.

Also, look at the specs for the springs Howard’s recommends(98632) for those lobes in a BB.

Calculate the open load at full lift for that spring if you were running the 720162-08 cam(I’ll give you a hint...... it’s a fair amount higher than 360-370).

The low-ish spring load isn’t a problem(rpm wise)....... until it is.

Was that contributing to the early power peak of your engine?

Hard to say.

Last edited:

Ivoryk3ys78

Well-Known Member

Those springs may be your problem.

Last year we took my 72 Duster to the track

408

Trickflow 190

11.2 compression

Howard Solid 600/615 254/260@050 108 in at 103.5

Strip Dominator

800cfm DP

727/3500 4.10 / 28

I am pretty sure the springs are the same as you got on the big block heads. They are rated at 120 on the seat and a pac spring isntalled at 1.9.

It only did 113.5 in the 1/4. Something was definitely wrong..

After talking to my friend Mike we took off some springs and tested them. We tested a few at the install height and were only getting like 110 and you could see the scrub pattern on the tops of the valves had been moving around. The valves had been turning.

We started looking to try and find another spring that would work with that same install height and everything and ended up ordering Howards HRS-98632

Valve Spring Set Series:

Max Effort

Style Of Spring:

Dual

Outer Overall Diameter:

1.500

Outer Inside Diameter:

1.100

Inner Overall Diameter:

1.100

Inner Inside Diameter:

.816

Damper:

No

Closed Pressure:

145 @ 1.940

Open Pressure:

422 @ 1.250

Rate:

413

Max Lift:

.780

Coil Bind:

1.100

This ended up being a spring pressure of about 155 Seat Open 390/400 area.

We brought it to the track this year and the car did 118.5. We were not quite wide open we discovered the previous year but it wasn't by much.

I think your issue is those springs. I had wished I had bought the heads with the one size stronger spring.

The howard springs went right in though without anything else needed to be changed. Perfect for the 1.9 install height and everything. Went right in and they are not expensive. They are lik $140.

Howards Cams 98632 Howards Cams Performance Street/Strip Valve Springs | Summit Racing

I am also running there EDM oiling solid lifters. I would imagine when the spring breaks in a little the spring pressure will drop some.

Last year we took my 72 Duster to the track

408

Trickflow 190

11.2 compression

Howard Solid 600/615 254/260@050 108 in at 103.5

Strip Dominator

800cfm DP

727/3500 4.10 / 28

I am pretty sure the springs are the same as you got on the big block heads. They are rated at 120 on the seat and a pac spring isntalled at 1.9.

It only did 113.5 in the 1/4. Something was definitely wrong..

After talking to my friend Mike we took off some springs and tested them. We tested a few at the install height and were only getting like 110 and you could see the scrub pattern on the tops of the valves had been moving around. The valves had been turning.

We started looking to try and find another spring that would work with that same install height and everything and ended up ordering Howards HRS-98632

Valve Spring Set Series:

Max Effort

Style Of Spring:

Dual

Outer Overall Diameter:

1.500

Outer Inside Diameter:

1.100

Inner Overall Diameter:

1.100

Inner Inside Diameter:

.816

Damper:

No

Closed Pressure:

145 @ 1.940

Open Pressure:

422 @ 1.250

Rate:

413

Max Lift:

.780

Coil Bind:

1.100

This ended up being a spring pressure of about 155 Seat Open 390/400 area.

We brought it to the track this year and the car did 118.5. We were not quite wide open we discovered the previous year but it wasn't by much.

I think your issue is those springs. I had wished I had bought the heads with the one size stronger spring.

The howard springs went right in though without anything else needed to be changed. Perfect for the 1.9 install height and everything. Went right in and they are not expensive. They are lik $140.

Howards Cams 98632 Howards Cams Performance Street/Strip Valve Springs | Summit Racing

I am also running there EDM oiling solid lifters. I would imagine when the spring breaks in a little the spring pressure will drop some.

The springs are TFS-16893. Installed pressure of 120lbs at 1.875, and open pressure of 394lbs at 1.175. These are the springs that trick flow sends with their flat tappet 240 heads. I spoke to Howard's cams yesterday to pick their brains about things, and he was a little concerned about the spring pressure. He said he generally doesn't like to see more than 360-370.

Anyway, he recommended getting the cranking pressure up in the 185 region, moving in two degree incriments until it gets there. I'll be ordering the stall converter today, then get that in and get the engine dropped in quick. At that point I'll pull the timing cover and check/adjust the cam timing so I can crank it over.

I plan on 30% street and 70% bracket with the car. Just taking the kids to school, a few local car shows and such.

-

Similar threads

- Replies

- 53

- Views

- 5K

- Replies

- 17

- Views

- 8K