with increasing noise in clutch took it in to shop for look at throw-out and other clutch components - got message that engine is shifting around when clutch is operated. Has not dropped trans yet - Will see mech. in a.m. and discuss - what the heck might be going on here? any comments welcome. thnx this is slant 6, 3spd to big block 4 spd conversion that has been doing fine for a while..

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'68 Barracuda 383 4spd - throw-out bearing/other issues?

- Thread starter Dave NEO

- Start date

-

yea, thnks. Suppose that could be another possible cause of noisy clutch action.. well we'll see tomorrow I suppose..Was hoping for simple fix; I may used all of mine up.... lol .

I'm thinking fix any suspect mounts and see of it improves the situation before even getting into the clutch/trans.

I'm thinking fix any suspect mounts and see of it improves the situation before even getting into the clutch/trans.

OK so it has wrong z-bar which makes it too short to line up with a straight rod off the clutch fork, hence the s-shaped rod - also the bracket with pivot point on trans is a home made affair that does not look like it lines up perfectly with linkage. I saw engine and trans actually lift up on their mounts when clutch is operated.. Starting point seems to be getting right linkage and then go with new TO and pilot bushing. Comments /suggestions appreciated. Anyone been down similar road?

jbc426

Well-Known Member

OK so it has wrong z-bar which makes it too short to line up with a straight rod off the clutch fork, hence the s-shaped rod - also the bracket with pivot point on trans is a home made affair that does not look like it lines up perfectly with linkage. I saw engine and trans actually lift up on their mounts when clutch is operated.. Starting point seems to be getting right linkage and then go with new TO and pilot bushing. Comments /suggestions appreciated. Anyone been down similar road?

The engines are designed with the movement of the engine taken into consideration. That's why there are pivots on the clutch linkage. Make sure you limit the total engine travel with a chain or interlocking motor mount like a Mity Mount or Poly mount from Schumacher. I just put an American Power train hydraulic clutch in my '70. Mine was a bit tough to bleed, but it is amazing once in and bleed.

well,,,some vibration vs. engine and trans rising and falling with push pf clutch pedal seems different to me but maybe not. I don't know, we'll check mounts which at first glance see intact but a little twisted in their locations..I am hoping right now the new Z-bar listed for this year A-body big block is a fit in that tight location and aligns with clutch fork.

- Joined

- Jan 8, 2012

- Messages

- 7,098

- Reaction score

- 4,247

well,,,some vibration vs. engine and trans rising and falling with push pf clutch pedal seems different to me but maybe not. I don't know, we'll check mounts which at first glance see intact but a little twisted in their locations..I am hoping right now the new Z-bar listed for this year A-body big block is a fit in that tight location and aligns with clutch fork.

So why post this knowing you have an incorrect Z-Bar for the application? Seems counter productive and you will get unrelated results to the real issue.

So why post this knowing you have an incorrect Z-Bar for the application? Seems counter productive and you will get unrelated results to the real issue.

Well I did not know until today when under lift with mechanic that z-bar looks wrong. If you are just looking to criticize/***** about someone's posts you'd be better off to just ignore them. Otherwise thanks to all for any suggestions/positive comments on this. I am not a mechanic but am trying as best as I can to describe issue(s).

- Joined

- Jan 8, 2012

- Messages

- 7,098

- Reaction score

- 4,247

Well I did not know until today when under lift with mechanic that z-bar looks wrong. If you are just looking to criticize/***** about someone's posts you'd be better off to just ignore them. Otherwise thanks to all for any suggestions/positive comments on this. I am not a mechanic but am trying as best as I can to describe issue(s).

Easy, not trying to criticize! Pics always help! Reading your posts you already know it was a slanty upgraded to B.B. I made the assumption you did this and bad on my part! For that I aplolgize!

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,940

- Reaction score

- 12,290

THe engine and trans must weigh over 600pounds.

If it is noticeably "lifting" during clutching, that ain't right. There is no force going in a vertical direction. All the force is fore and aft.Well maybe a small vertical vector from the Hi-mounted inboard Z-bar pivot. As said pics would help a lot!

If it is noticeably "lifting" during clutching, that ain't right. There is no force going in a vertical direction. All the force is fore and aft.Well maybe a small vertical vector from the Hi-mounted inboard Z-bar pivot. As said pics would help a lot!

TrailBeast

AKA Mopars4us on Youtube

THe engine and trans must weigh over 600pounds.

If it is noticeably "lifting" during clutching, that ain't right. There is no force going in a vertical direction. All the force is fore and aft.Well maybe a small vertical vector from the Hi-mounted inboard Z-bar pivot. As said pics would help a lot!

Exactly, and none of which would likely be the cause for noise from the clutch.

Stabilizing that motor and a new TO bearing would be a great start, as long as nothing else is worn or dry.

Possibly even a pilot bushing/bearing could be worn out.

If I saw it and heard it in person I could tell ya exactly what part was making noise.

Probably not over the internet and speakers though.

thnx -we are planning to replace Z-bar, clutch adjustment rod, and TO and pilot bushing. I watched motor and trans lift slightly as he pushed down clutch pedal. Need to see bolts are tight I suppose. Noise thrashing/grind/dragging soind as you let up clutch pedal about half way engaged- fully up it goes away. especially notceable in revers but also in 1-2-sometimes 3. thnks for all comments

Daves69

Well-Known Member

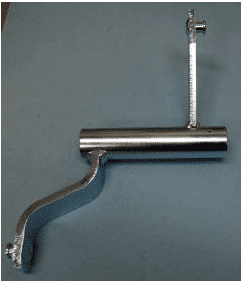

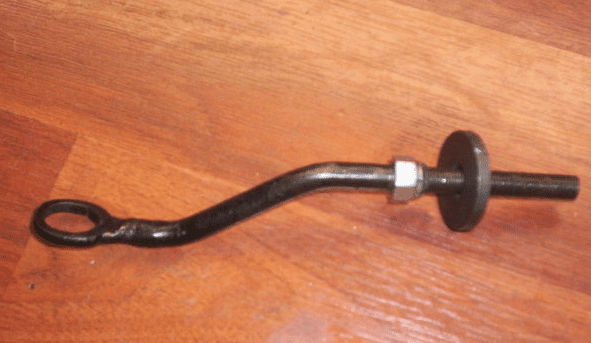

This...….

Not this...….

Correct part geometry can reduce pedal effort and deflection in your assembly.

Then too, a high load clutch cover can contribute to deflection somewhere in the total assembly.

Is the frame side ball mount flexing as you work the clutch?

Not this...….

Correct part geometry can reduce pedal effort and deflection in your assembly.

Then too, a high load clutch cover can contribute to deflection somewhere in the total assembly.

Is the frame side ball mount flexing as you work the clutch?

You should be able to see this as you rev the engine in neutral. It'll move even more as you let off the clutch adding load.The engines are designed with the movement of the engine taken into consideration. That's why there are pivots on the clutch linkage......

jbc426

Well-Known Member

thnx -we are planning to replace Z-bar, clutch adjustment rod, and TO and pilot bushing. I watched motor and trans lift slightly as he pushed down clutch pedal. Need to see bolts are tight I suppose. Noise thrashing/grind/dragging soind as you let up clutch pedal about half way engaged- fully up it goes away. especially notceable in revers but also in 1-2-sometimes 3. thnks for all comments

Does it make the noise with the clutch fully depressed and the transmission in gear and or in neutral? Which?

I found that spending a bit of time massaging the Z-bar and rod ends so they lie flat on the pivot points and are aligned in straight lines towards the opposite ends of the rods helped my linkage feel more efficient. I lube all contact points with CRC synthetic disc brake grease too. It won't wash out, has moly, PTFE(Teflon) and graphite mixed in a very high and low rated synthetic grease that won't attack plastic, rubber or nylon. It's an amazing lubricant.

They also sell a complete z-bar refreshing kit from Mopar that's available on-line at a lot of Mopar parts houses.

It is a HD clutch that requires more effort. Was looking at motor from up top and then underneath (engine off) when clutch was being worked as it was motor ans trans were re rising and falling. I am trying to say this was different than watching engine move around when you rev it.

both actually sometimes, but more often when it has been put in gear and you want to let up and roll off. you can hear and feel it in pedal.Does it make the noise with the clutch fully depressed and the transmission in gear and or in neutral? Which?

I found that spending a bit of time massaging the Z-bar and rod ends so they lie flat on the pivot points and are aligned in straight lines towards the opposite ends of the rods helped my linkage feel more efficient. I lube all contact points with CRC synthetic disc brake grease too. It won't wash out, has moly, PTFE(Teflon) and graphite mixed in a very high and low rated synthetic grease that won't attack plastic, rubber or nylon. It's an amazing lubricant.

They also sell a complete z-bar refreshing kit from Mopar that's available on-line at a lot of Mopar parts houses.

jbc426

Well-Known Member

both actually sometimes, but more often when it has been put in gear and you want to let up and roll off. you can hear and feel it in pedal.

Sounds like a pilot bearing, but could also be a dry/worn throw out bearing. The only time the pilot bearing spins is when the input shaft is free from the crankshaft as the clutch is fully depressed/ disengaged. If the trans is in neutral, the input shaft will often spin with the crank even when the clutch is fully depressed making less noise than when the input shaft of the transmission is held by being in engaged by being in gear, more so without the car moving.

I've noticed they are using a very low grade grease in the recent replacement throw out bearings. I've had bad luck with the McCleod units specifically. I have a Hays unit in my car now. Probably made in China. The Chines manufacturers will cut corners on this type of thing to put more money in their pockets until they are called on it.

If you are running a bushing type pilot bearing and are replacing it, you will need to hold the new replacement bushing down on the palm of your hand or thumb, fill it with a high quality gear oil and compress the trapped fluid with your other thumb until the compressed oil oozes through the walls of the bushing.

Once it does, clean it off well and drive it in place. It does help if you can insert the input shaft of the transmission into it to check the internal size and fit before you try doing the final assembly.

I like the roller bearing pilots myself, and they are interesting to change out too.

Last edited:

-