Looking for a suggestion on an aftermarket manual steering box for a 68 Barracuda. I've been on a few websites and the options are endless. Any thoughts? Let me know if any additional info is needed to narrow down an option.

68 Barracuda Manual Steering Box

- Thread starter Mcfarlrm

- Start date

-

We offer three ratios stock 24:1, 20:1 or fast ratio 16:1. The 20:1 is a happy medium meaning effort wise. Please let me know if you have any question?

Thanks

James From

PST

Thanks

James From

PST

I used Steer and gear for a rebuilt unit for my 69, have been pleased over 8 years.

I am however close to going PS! finally!

I am however close to going PS! finally!

72Duster440

Well-Known Member

I like my 20:1 PST box, very reasonably priced too.

Dartsun

Mopar Dude

I have a pst 16:1 manual box in my 65 dart 273. I like it and would purchase again.

Order the 20:1 this morning. Appreciate the help here.We offer three ratios stock 24:1, 20:1 or fast ratio 16:1. The 20:1 is a happy medium meaning effort wise. Please let me know if you have any question?

Thanks

James From

PST

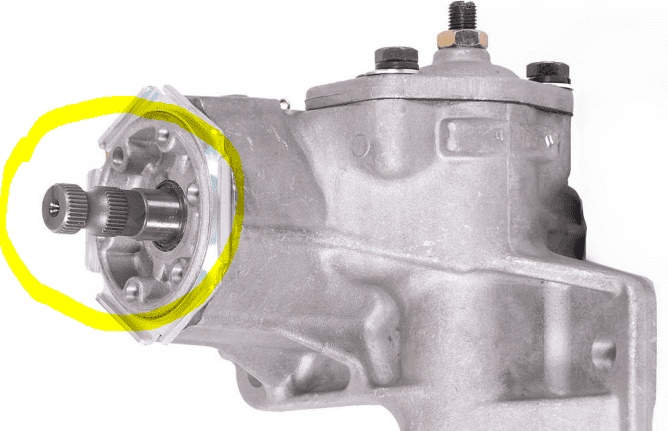

Got around to installing the steering box. It did improve the tightness of the steering while cruising around, which I am happy with. However, there is still a bunch of slack in the steering wheel when parked. I did loosen the nut and tightened the screw a quarter twist at a time to see if it improved anything and it did not help. I tightened it a full turn and half and still no improve before backing it back down to the factory setting. There is no play in the pitman arm or any or steering linkage. The issue seems to arise at the highlighted part below. This rod within the box has slack in it while parked. Is this slack normal or is this pointing to a defective steering box that needs to be replaced? Want to rule everything out before I take the time to replace the box completely.

72Duster440

Well-Known Member

Mine was like that too, like a dead spot in the center? Have someone yaw the steering wheel back and forth while you look at the gear box. The sector shaft on mine (20:1 PST) would move side to side considerably before it started to rotate. PST sent me a new box no questions asked, but I haven't been able to get time to swap it out to see if the problem went away yet.

That is exactly what I did to locate the issue with the slack and exactly where the issue was. A bunch of slack before the wheels start to rotate. PST is sending me a new box as well but the time it takes to install a second time around to see if it fixes the issue is a huge inconvenience. If this is indeed a manufacturer defect PST needs to address this issue if it is common. Hoping that a new box fixes it and if not, very unfortunate that this was a recommendation. Hoping to hear back from the marketing manager from PST on this thread.Mine was like that too, like a dead spot in the center? Have someone yaw the steering wheel back and forth while you look at the gear box. The sector shaft on mine (20:1 PST) would move side to side considerably before it started to rotate. PST sent me a new box no questions asked, but I haven't been able to get time to swap it out to see if the problem went away yet.

72Duster440

Well-Known Member

Agreed. Mine being a big block with massive headers, its a good 5-6 hour job minimum to swap the box out, which is why I haven't done it yet. I'm not sure what I will do if the problem is still there after trying the second box. It's good on them to send me another one with no questions asked, but I have a feeling I will have the same issue. My thought is the housing isn't strong enough to handle the increased stress seen by changing the gear ratio and it is allowing the housing to flex which allows the gear mesh to change, creating slop. Which is amplified with sticky front tires and a big block in my case.

72Duster440

Well-Known Member

This will spund silly, but aside from the dead spot in the center, I am happy with the 20:1 ratio box from a handling/steering effort point of view. Just really hoping this replacement box gets rid of the dead spot issue, but reading your post doesn't give me hope.

Yeah, seeing that someone else is having the exact same issue is disconcerting. To your point, happy with handling/steering while in motion but one of the biggest reasons for the purchase was to tighten the slack in my steering wheel. My install wasn't as labor intensive as yours (small block 360 with Hedman Tight Tubes) but still a few hours just to be disappointed.

72Duster440

Well-Known Member

That was the entire reason for my upgrade too. I had replaced all of the tie rods and idler/pitman arm the year before and the car still wandered a bunch due to a dead spot even after tightening up the stock box. Was really expecting to eliminate that issue with the new one, but I was wrong.

I replaced my idler arm recently. Pitman arm and tie rods are solid as a rock (no Chevy pun intended). I ruled out all other causes before contacting PST to troubleshoot. Unfortunately, any sort of guidance/feedback/known issue when asked was met with "we will send a replacement."

72Duster440

Well-Known Member

Let's hope the replacements they sent us are an improved design and better than the first batch!

72Duster440

Well-Known Member

My first one was sent almost years ago and the replacement was sent at the end of last cruising season. I plan to install it tomorrow actually, I had to remove everything steering related to tip my engine down enough to swap my trans, now that the teans is in, the steering will be going back in tomorrow. I'll report my findings, but don't hold your breath!

Did you get around to installing the new box? I received my replacement but hesitant to install it. You would think that these would come preset to dead center from the factory but mine was completely right locked.

@PST - any comments/feedback regarding these issues that a couple of your customers are experiencing?

@PST - any comments/feedback regarding these issues that a couple of your customers are experiencing?

72Duster440

Well-Known Member

No I did not. My son was pretty sick last weekend, so that took priority. I'm gonna try this weekend, but considering it was 17 degrees this morning, I have a while to get it back together!

I haven't checked the new one to see if it was centered or not.

I haven't checked the new one to see if it was centered or not.

72Duster440

Well-Known Member

I pulled my new one off the shelf, it was turned all the way to the right as well.

Dave999

Well-Known Member

if you have pending return with PST cool, they should be able to make a decsion on if there is a fault with the steering box.

If the box is assembled with care and good parts, any movement of the input shaft should result in a movement of the sector.

if you can turn the input shaft with no movement of the sector then one of these issues is the cause

1) Sector shaft teeth are not meshed with ballnut teeth to the appropriate specification in the middle of the box travel (straight ahead). The teeth on each of theses components are wedge shaped in profile when looked at, from the side and when looking face in. The sector tooth is wider at the top and sticks out further at the top than at the bottom and the bullnut tooth is the oposite

The bolt and locknut on the cover of the box dictate how hard the sector shaft teeth are wedged down into the ballnut teeth, bolt and locknut dicate how hard you wege those opposing tooth shapes together.

Any space between the two results in sloppyness. But too much "wedge" leads to wear and a very very stiff section in the middle of the box.

If the upper mid and lower sector bushes or bearings are worn out the sector is not well supported so you can not depend on the mesh between its teeth and the ballnut.

2) The ballnut, worm screw and the ball bearings used between them, have a tollerance stack up, in the worst-case direction. thread in ballnut too big/loose, thread on worm screw too small/loose, or the ball bearings that sit in the threads between the two parts are too small. given that we are pretty good at making ball bearings spehrical, and, to size i'd assume something with the nut or the worm. you might get away with hardchroming the parts to make them just a bit bigger or trying a bag of different size balls, you need about 60 and hardened makes sense.

3) the area you highlight in the picture. The hex ring is a big lock nut. its is tightend round a thread cut into the screw-in aluminium end to the steering box. On assembly and before the sector is installed the is section should be screwed in to give a precise level of preload to the worm shaft bearings, measured as a turning resistance, and the lock ring is applied to keep this set. The worm shaft rides on caged ball bearings much like those used on the peddle crank of a raleigh or schwinn bike. If this has not been done properly or the bearings are broken, turning the input shaft allows it to rise or sink a tiny amount in the case before it starts to move the ballnut, hence when magnified at the edge of a massive mopar steering wheel you see this as play

any one of these things could be casusing your issue , and all are hard to spot with the steering box in the car.

other things cause the same symptoms.

busted steering box mounting on K frame or chassis depending on age, or which side the driver sits.

loose column causing worn or damage to the pot coupler or rag joint

worn out pitman arm track rod ends etc

A nicely rebuilt or brand new steering box should be stiff in the middle. This is by design and stops the teeth chattering and wearing between ballnut and sector when you drive straight ahead, you will find it hard to turn the input spline with your hand, without it being uncomfortable and the smallest movement you achieve should create an instant movement of the sector.

if you can twist the input spline and get no sector movement the box is potentially at fault.

If all adjusted correctly, and you still have the problem, its a problem with the parts used to build the box, not the setup.

I've built a few of these over the years and have found a range of horrors, but all were rebuilt to fight another day with no slop.

Dave

If the box is assembled with care and good parts, any movement of the input shaft should result in a movement of the sector.

if you can turn the input shaft with no movement of the sector then one of these issues is the cause

1) Sector shaft teeth are not meshed with ballnut teeth to the appropriate specification in the middle of the box travel (straight ahead). The teeth on each of theses components are wedge shaped in profile when looked at, from the side and when looking face in. The sector tooth is wider at the top and sticks out further at the top than at the bottom and the bullnut tooth is the oposite

The bolt and locknut on the cover of the box dictate how hard the sector shaft teeth are wedged down into the ballnut teeth, bolt and locknut dicate how hard you wege those opposing tooth shapes together.

Any space between the two results in sloppyness. But too much "wedge" leads to wear and a very very stiff section in the middle of the box.

If the upper mid and lower sector bushes or bearings are worn out the sector is not well supported so you can not depend on the mesh between its teeth and the ballnut.

2) The ballnut, worm screw and the ball bearings used between them, have a tollerance stack up, in the worst-case direction. thread in ballnut too big/loose, thread on worm screw too small/loose, or the ball bearings that sit in the threads between the two parts are too small. given that we are pretty good at making ball bearings spehrical, and, to size i'd assume something with the nut or the worm. you might get away with hardchroming the parts to make them just a bit bigger or trying a bag of different size balls, you need about 60 and hardened makes sense.

3) the area you highlight in the picture. The hex ring is a big lock nut. its is tightend round a thread cut into the screw-in aluminium end to the steering box. On assembly and before the sector is installed the is section should be screwed in to give a precise level of preload to the worm shaft bearings, measured as a turning resistance, and the lock ring is applied to keep this set. The worm shaft rides on caged ball bearings much like those used on the peddle crank of a raleigh or schwinn bike. If this has not been done properly or the bearings are broken, turning the input shaft allows it to rise or sink a tiny amount in the case before it starts to move the ballnut, hence when magnified at the edge of a massive mopar steering wheel you see this as play

any one of these things could be casusing your issue , and all are hard to spot with the steering box in the car.

other things cause the same symptoms.

busted steering box mounting on K frame or chassis depending on age, or which side the driver sits.

loose column causing worn or damage to the pot coupler or rag joint

worn out pitman arm track rod ends etc

A nicely rebuilt or brand new steering box should be stiff in the middle. This is by design and stops the teeth chattering and wearing between ballnut and sector when you drive straight ahead, you will find it hard to turn the input spline with your hand, without it being uncomfortable and the smallest movement you achieve should create an instant movement of the sector.

if you can twist the input spline and get no sector movement the box is potentially at fault.

If all adjusted correctly, and you still have the problem, its a problem with the parts used to build the box, not the setup.

I've built a few of these over the years and have found a range of horrors, but all were rebuilt to fight another day with no slop.

Dave

Dave999

Well-Known Member

just saw comments about the box being all the way left or right

you need to centre it before you install it

line up the closest master spline on the sector (it will have 2 or 4) with the case seam at the stiff point in the middle.

dave

you need to centre it before you install it

line up the closest master spline on the sector (it will have 2 or 4) with the case seam at the stiff point in the middle.

dave

72Duster440

Well-Known Member

I spun the input on mine, it is much harder to spin near the center and gets easier the closer I get to the lock, which i thought was strange. I had my column out at the time so I slid the steering coupler on to make sure it fit, since the last one was a nightmare to install. It was pretty hard to get on all the way, and needed a couple love taps with a mallet. Well, apparently that was a mistake because now I can't get the coupler back off. I guess I'll be leaving it on and assuming the coupler while I install the column. Should make crimping the seal plate on real fun.

scatpackbee

Well-Known Member

I was thinking of purchasing a 20:1 manual box from PST but I’m very hesitant now on going through all the time for the removal and install then finding out the new box has issues.

I don’t have that kind of time to waste.

I don’t have that kind of time to waste.

Last edited:

-