billytuffnuts

Well-Known Member

Hey Everyone,

I pulled apart the valve body from my 727 to install the TF2 Shift Kit and I came across a couple of concerns while cleaning it. Since I'm not too familiar with VB's I'm hoping some of you can give some advice. I'm also planning on having a trans shop put it through their parts washer as brake kleen doesn't seem to be working as well as I had hoped.

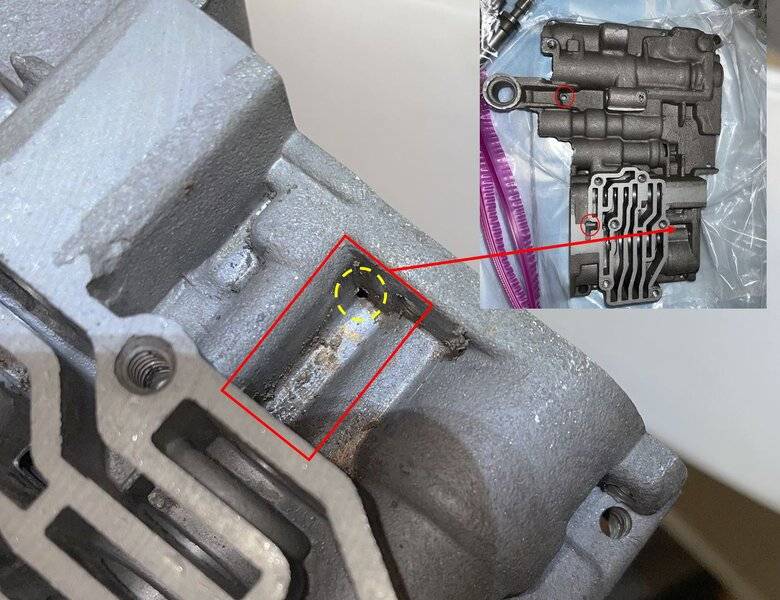

1) On the top of the VB, between the 1-2 & 2-3 shift valves, I found some kind "crud" in a valley (red rectangle) and when scraping it off, the bottom layer was copper and has the texture of copper anti-seize. After removing it I found a hole in the casting (yellow circle).

Should this hole be here? And what could this copper stuff be/why would it be on my valve body? I later found it in a couple of other spots including in the transfer plate passages (very little - see red circles

2) I noticed a defect (hole) in one of the pockets on the transfer plate - It doesn't look to be part of any passage but I'm not sure if I need to be worried about it or not.

I pulled apart the valve body from my 727 to install the TF2 Shift Kit and I came across a couple of concerns while cleaning it. Since I'm not too familiar with VB's I'm hoping some of you can give some advice. I'm also planning on having a trans shop put it through their parts washer as brake kleen doesn't seem to be working as well as I had hoped.

1) On the top of the VB, between the 1-2 & 2-3 shift valves, I found some kind "crud" in a valley (red rectangle) and when scraping it off, the bottom layer was copper and has the texture of copper anti-seize. After removing it I found a hole in the casting (yellow circle).

Should this hole be here? And what could this copper stuff be/why would it be on my valve body? I later found it in a couple of other spots including in the transfer plate passages (very little - see red circles

2) I noticed a defect (hole) in one of the pockets on the transfer plate - It doesn't look to be part of any passage but I'm not sure if I need to be worried about it or not.