You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

8 3/4 brace welding

- Thread starter mbaird

- Start date

-

pishta

I know I'm right....

If you do, tack it up and weld about 3 inches at a time and move to the other side. What are you trying to accomplish?

this will be going behind a 408 solid roller motor and I just want to make sure it can handle a launch or 2. It wont be a dedicated drag car.... Maybe 2 races per year.

HP could be in the 500s depending on my cam choice.... I dont plan on 5k clutch dumps but....

HP could be in the 500s depending on my cam choice.... I dont plan on 5k clutch dumps but....

diymirage

HP@idle > hondaHP@redline

Do I need to weld the entire length of the brace ?

Seems like overkill...

and bracing a 8 3/4 rear end doesnt seem like overkill ?

if your going to go through the trouble of welding up a perfectly good rear end, you might as well do it properly and weld it all the way

but, as pishta said, weld it in 3 inch increments, then spin it around welding the other said (this will keep it from getting too hot and warping)

But will it really be any stronger by welding the entire length of it ? The perches are only held on by two 3" welds and they are going through rotational torque that would be far greater than the flexing of the tubes... I would assume.

Will it potentially do more harm than good ?

There must be a point of diminishing returns..

Will it potentially do more harm than good ?

There must be a point of diminishing returns..

mderoy340

Well-Known Member

Best to use a jig to hold everything in place when welding a back brace.

mopowers

Well-Known Member

The walls on an 8-3/4 housing are relatively thin (that's the reason for a back brace in the first place). Even if only weld a few inches at a time, letting it cool between welds, you're still going to have distortion. Whether or not it'll be enough to cause any issue is anyone's guess. You'd be best off welding it in with an alignment jig in place. Even then, you may have to adjust the ends.

Now that's an idea I have not seen or read.It would also be a good idea to box the perches.

yellow rose

Overnight Sensation

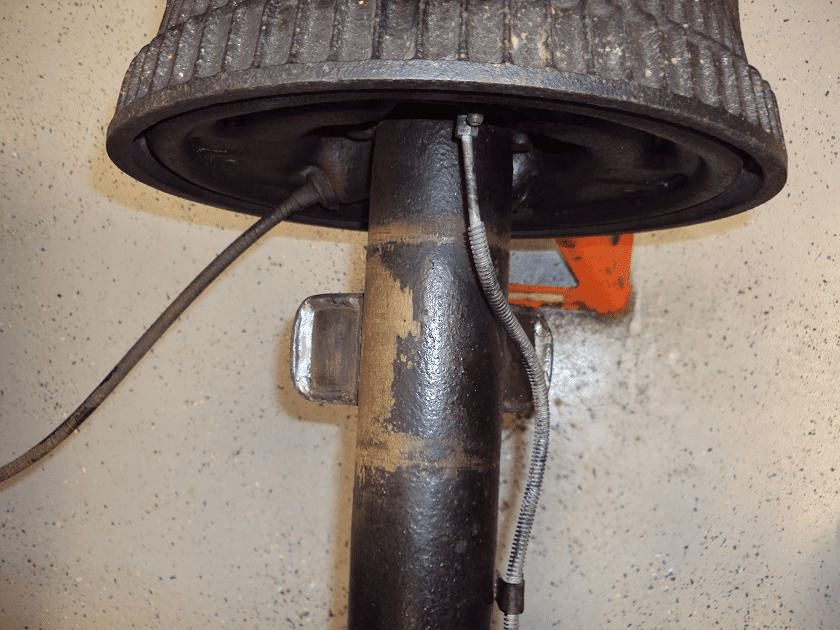

You should brace it to the flanges. You have to make holes in the braces to clear the U bolts.

It's worth it to go to the end. The loads end up at the end.

It's worth it to go to the end. The loads end up at the end.

HD Perch (Pair) - $39.00 : The Leader In Leaf Spring Innovation, - Calvert Racing and some pics I found on the www.

Someone posted a pic of a diff snout pointing straight down....

whitepunkonnitro

Well-Known Member

Wouldn't bolting on an adjustable pinion snubber be a little easier?

fishy68

Tyr Fryr's Inc.

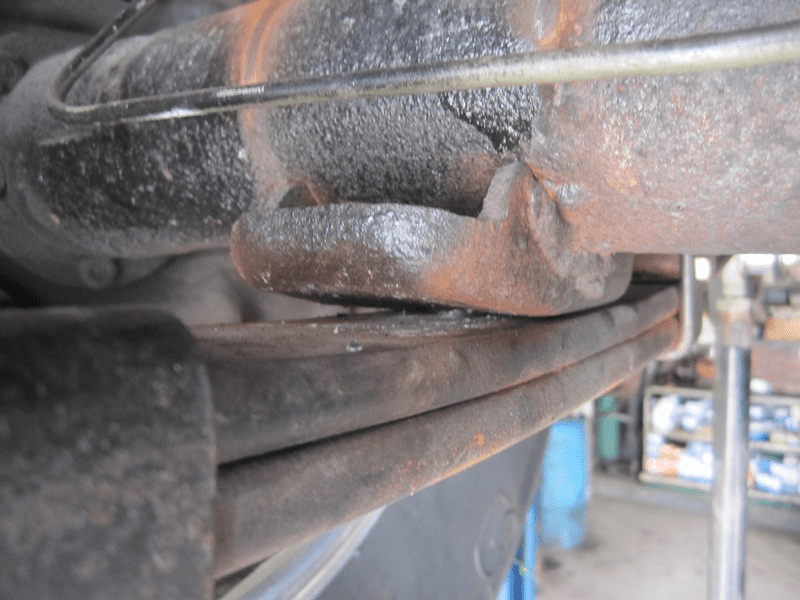

The brace does not go as far as the perches.

I believe its a Moser... The inner mounts are for a rear sway bar.

Boxing the perches is a new one to me as well..

Have you guys ever seen perch welds fail?

Sure have. Boxing the perches is pretty much a necessity for a race car IMO

'Cuda_ragtop

Woulda, Shoulda, 'Cuda!

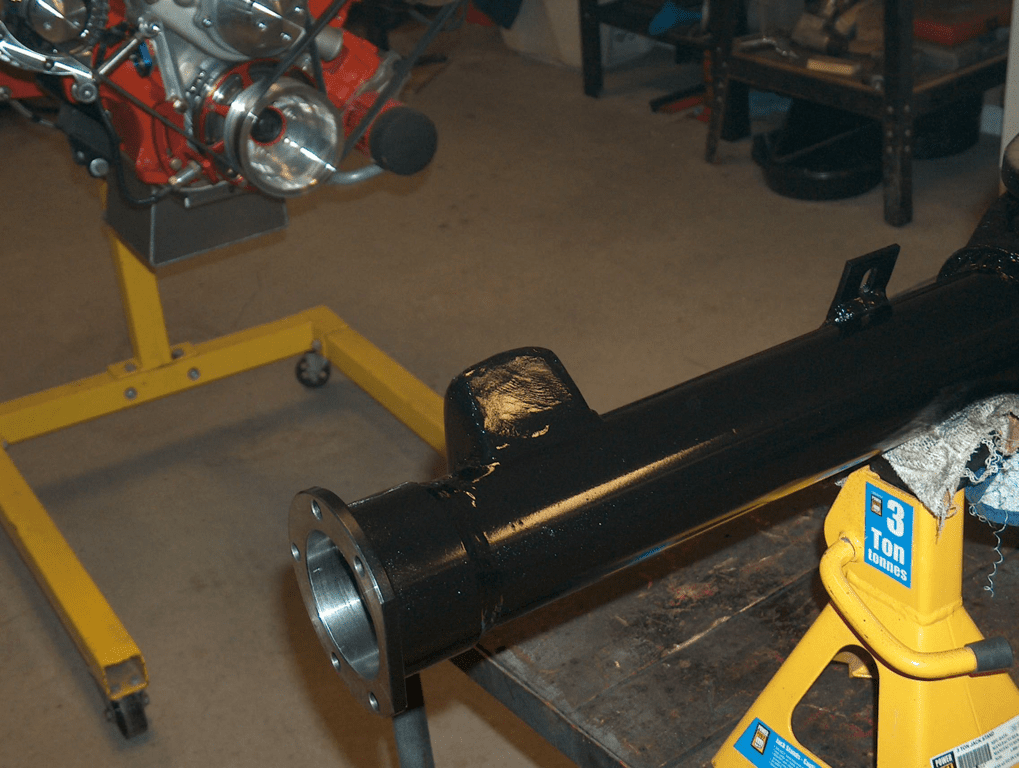

Had my 8-3/4 narrowed and new perches moved in.

It needed to be straightened a little too. Big shout out to Bill Scribner, Scribner Welding.

Scribner Welding and Distributing

It needed to be straightened a little too. Big shout out to Bill Scribner, Scribner Welding.

Scribner Welding and Distributing

-