ACME SS

Well-Known Member

Perhaps this should be posted under the tire and wheel category but I'm thinking more broad than just Mopar wheels.

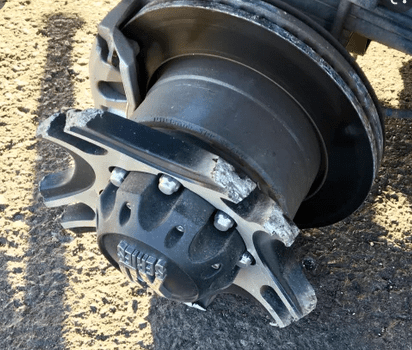

A few weeks back I was held up in traffic on a major highway near me. The reason being was an accident. When I finally got to the scene, there was a small Toyota sedan in the ditch with minor damage. The asphalt was mysteriously grooved in what looked like a spiral graph gone demonic and at the end of the mayhem was a lifted F-150 sitting on nothing but spokes...no rim or rubber to be seen anywhere. I didn't have time to pull out a camera to get a picture but it looked similar to the picture I found on the interweb, posted below. It made me wonder about all these aftermarket wheels and how safe they are? What kind of alloys are they using? Quality inspections, etc... The old chinese cast metal vices with bondo comes to mind.

Anyways, I was just wondering if anyone has any thoughts on the subject. It seems odd you don't hear anything about this ever. Seems like the media went nuts over Firestone tires years back but nothing on this.

A few weeks back I was held up in traffic on a major highway near me. The reason being was an accident. When I finally got to the scene, there was a small Toyota sedan in the ditch with minor damage. The asphalt was mysteriously grooved in what looked like a spiral graph gone demonic and at the end of the mayhem was a lifted F-150 sitting on nothing but spokes...no rim or rubber to be seen anywhere. I didn't have time to pull out a camera to get a picture but it looked similar to the picture I found on the interweb, posted below. It made me wonder about all these aftermarket wheels and how safe they are? What kind of alloys are they using? Quality inspections, etc... The old chinese cast metal vices with bondo comes to mind.

Anyways, I was just wondering if anyone has any thoughts on the subject. It seems odd you don't hear anything about this ever. Seems like the media went nuts over Firestone tires years back but nothing on this.