white-lightning

Active Member

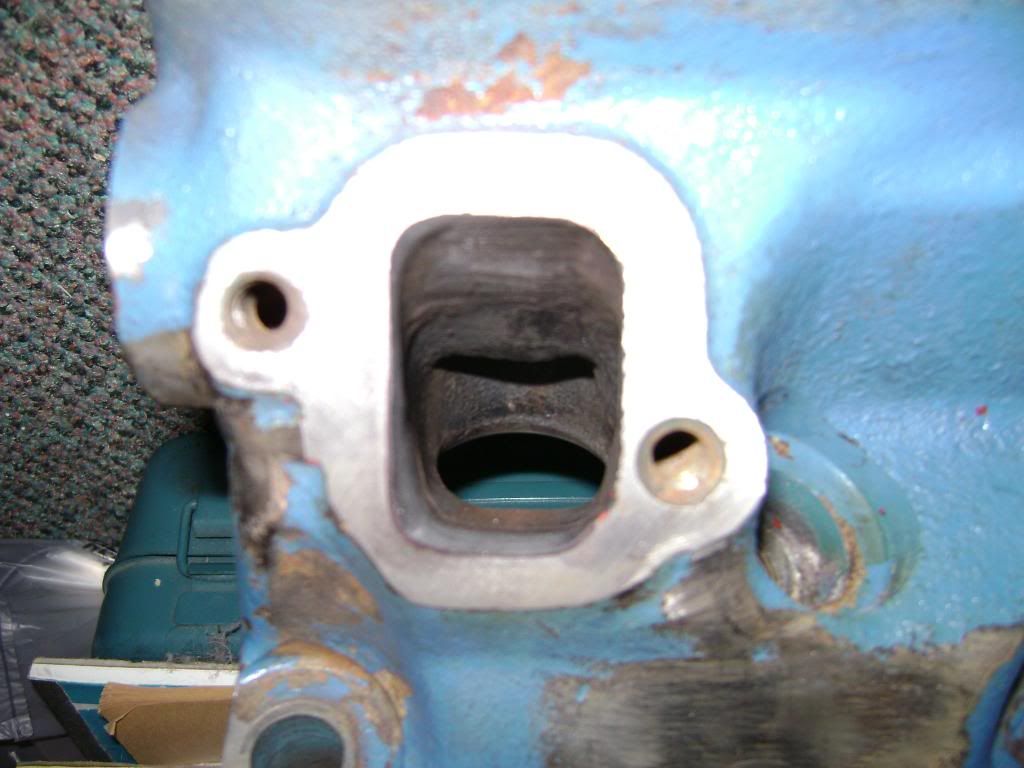

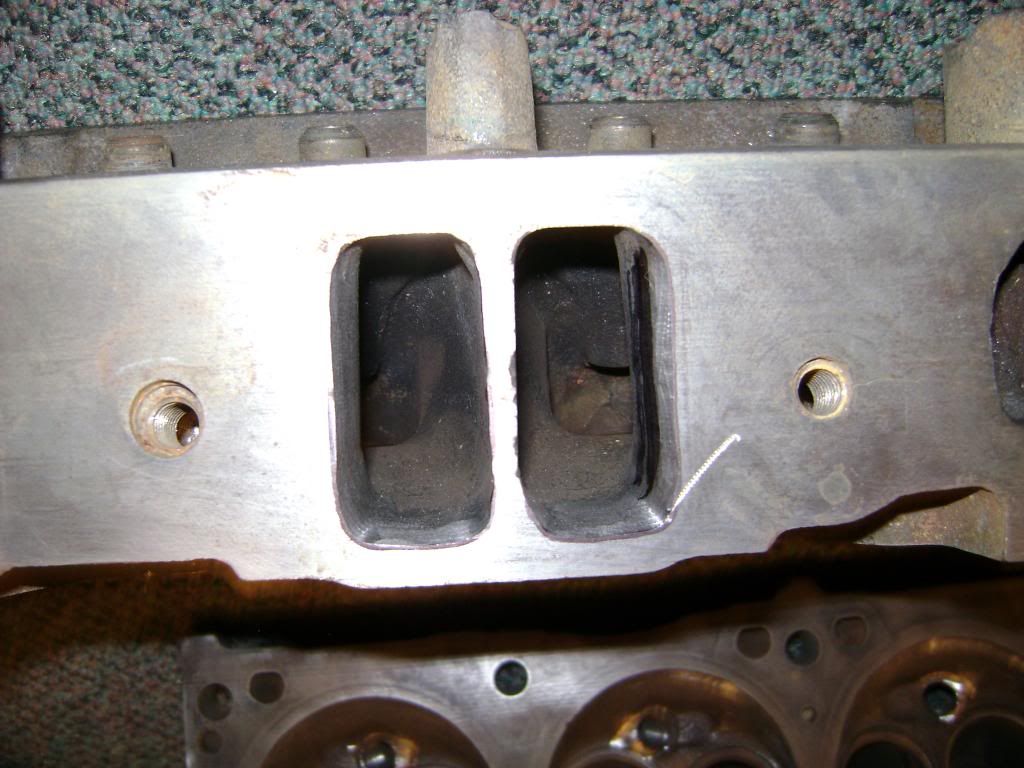

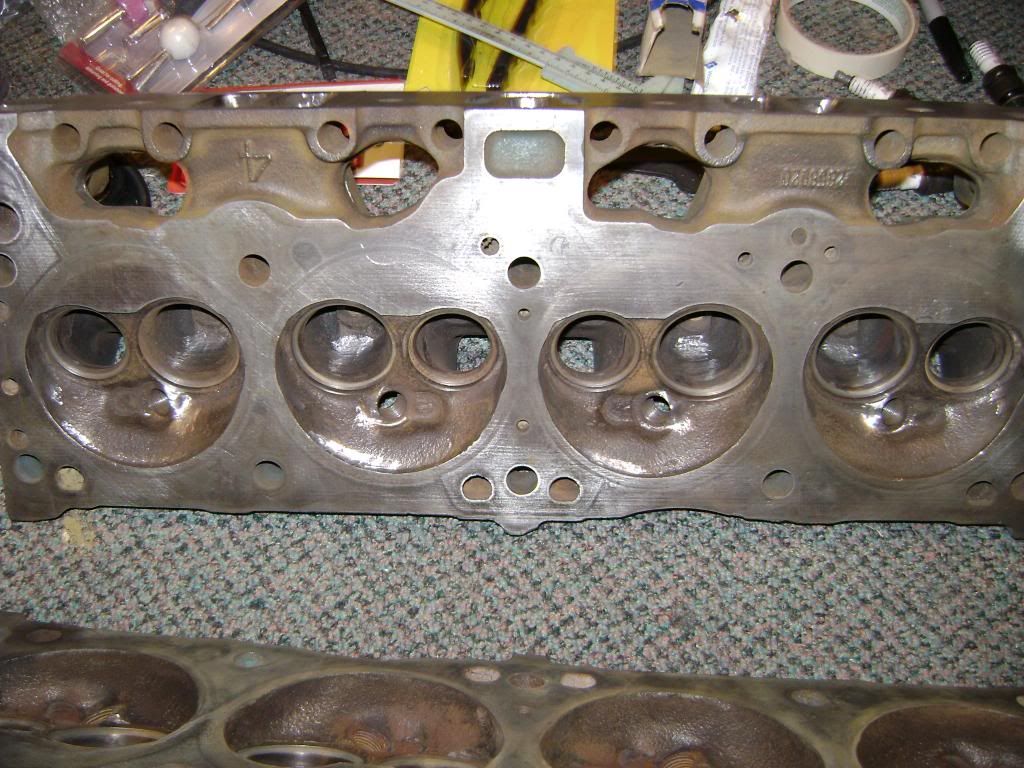

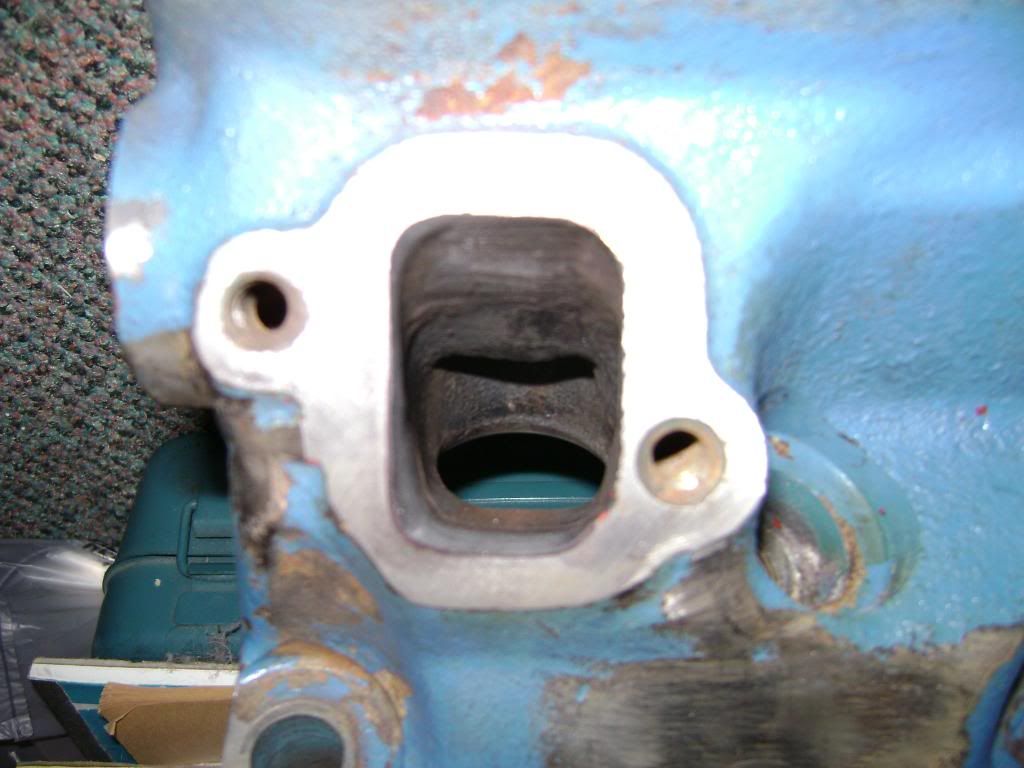

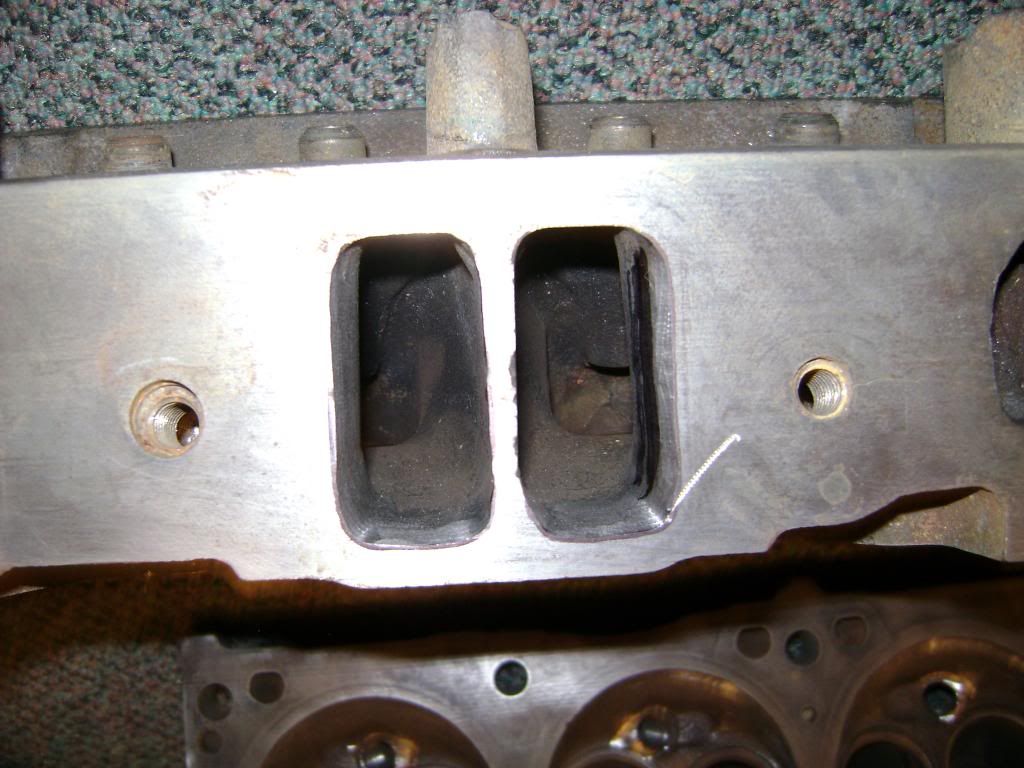

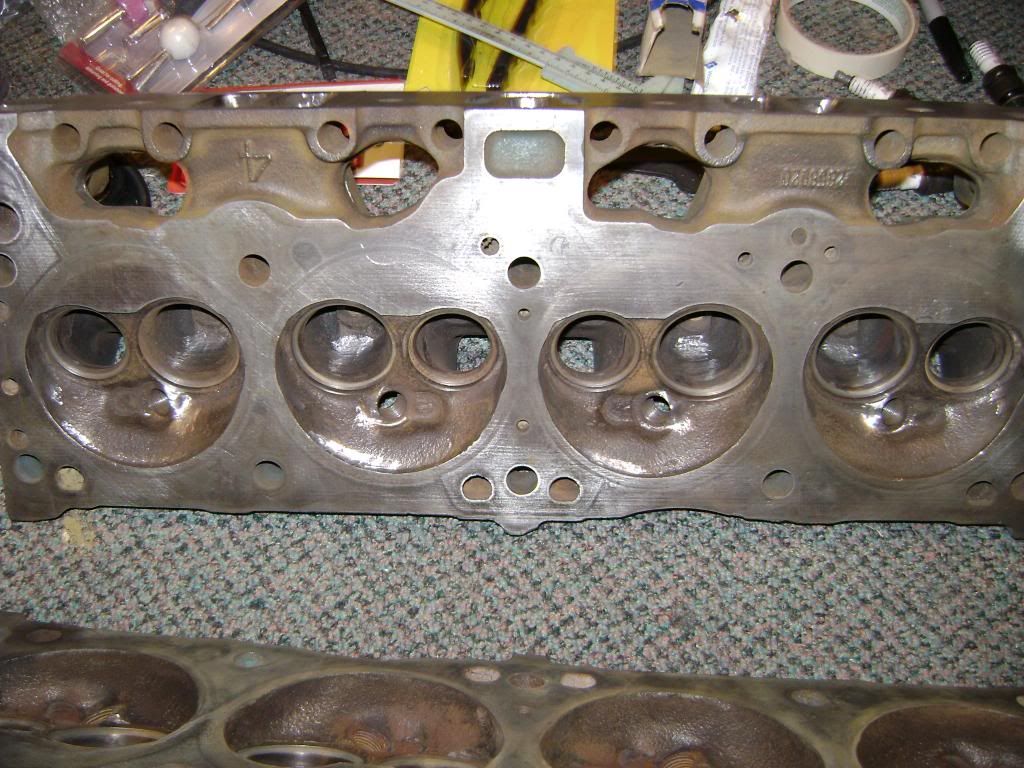

Here is what I have done so far on my 920s for my 273. I matched the intake and exhaust ports to my gaskets and smoothed the sharp edges of the spark plug bosses on one head. I plan on rolling the guide/roof of the ex. and smoothing the humps in the roof out the smoothing the whole port and bowl area with a burr and the go back with sanding rolls to really smooth it out. On the intake I plan on thinning the guide bosses and blending the bowls into the ports and smoothing with a burr to have a uniform surface. On with the pics