ok here are some pics of the start of the diff mods.. A few people have asked me to go into some detail.

Diff is out of a 1977 F100, good news with these is the housing is already setup so the pinion is in the centre, a lot of the car 9" housings have them offset. this also means each axle is the same length, makes it a little easier to do the calculations.

The housing.. I had to cut 220mm from each side for it to work in my val, scribe a line length ways up the tube to use as a reference when lining them back up to weld. I just used the 9" grinder to lop the tubes off, MAKE SURE you cut around 5mm into the waste steel as you wil need to square the ends and the housing off in a lathe.

If your lucky (like I was) the section you cut out of the tubes may have the old shock mount and/or spring saddle welded to it... this saves you a lot of cutting.

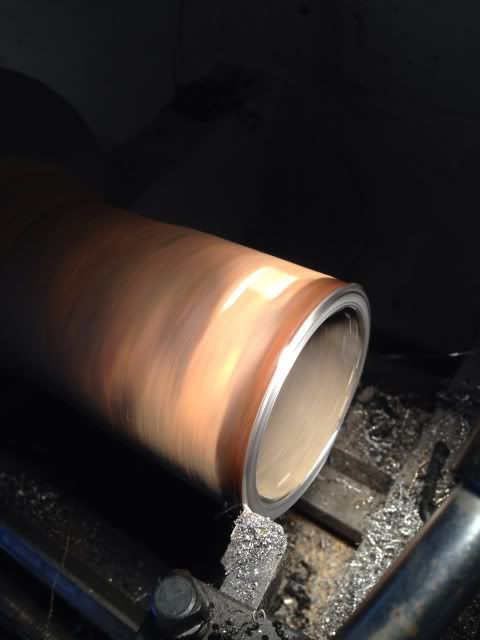

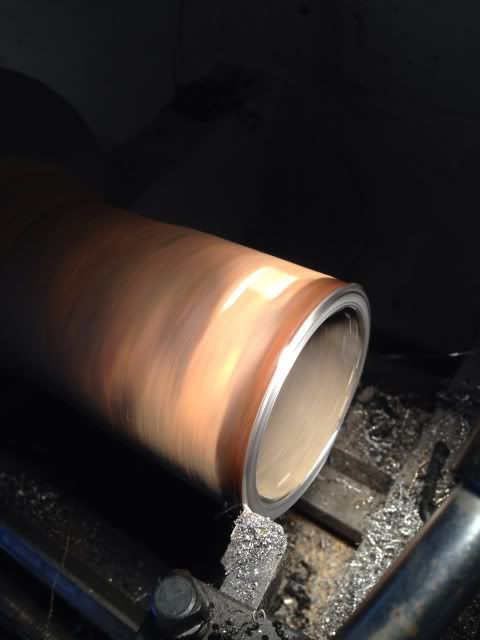

I then squared off the 2x ends in the lathe (pic below) removing the existing material up to my scribe mark.. I also trued these up in the lathe with a dial guage before machining.

the housing doesn't fit in my lathe so ill have to borrow one through the week and square those ends up.

Now for the axles and brakes!

Problem #1 is that I didnt realise that the F truck as a PCD of 5x5.5" instead of the 5x4.5" that I need!! so I knocked the studs out and am in the process of organising the to be redrilled. Not a real big deal just a bit of a pain.

problem #2.. the ea discs wont fit over the axle flanges, so I chucked the axles in a lathe and machined ~8mm off them, now the disc slip on nicely.

problem #3.. the centre hole in the ea discs wont fit over the axle snout of the F100 axles, you can either machine the disc out or machine the snout down. I chose the snout because its a lot easier to setup in the lathe to get a true measurement.. I used a dial guage to make sure the axle was true before machining.

this week ill be machining some press fit tubes up to join the housing and ends back together, dropping the axles off to be shortened and sourcing a centre. Then ill move onto making up some caliper brackets. So there will be more pics to come

Also got the shell in its last coat of primer!! I don't know how people can do it for a day job lol..