I may never understand everything there is too know about camshaft theory but Im not gonna give up trying to degree this camshaft. This isnt rocket science, seems to me a 10 year old child should be able to do this successfully so why can a 50 year old man do it?

EDIT: Uh cause some knumnuts put the wrong info online

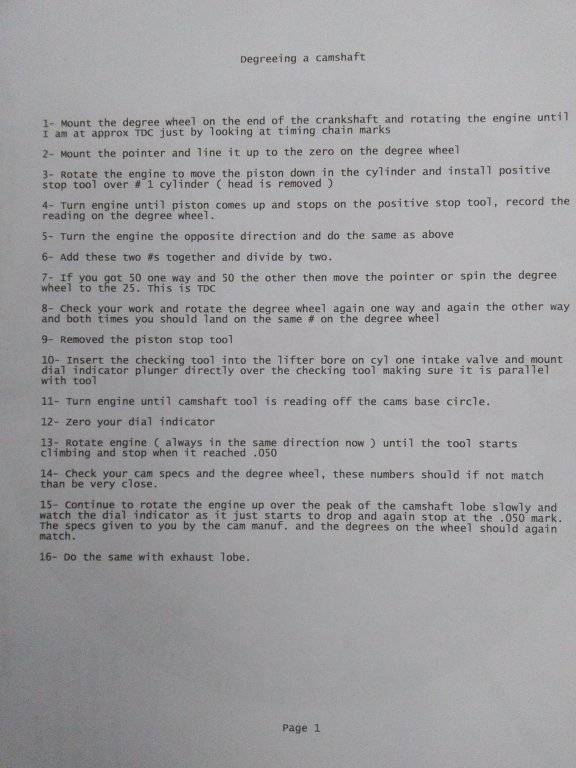

Below is the procedure I am following meticulously. I have tried this same procedure a couple of different times with same results.

First picture is my procedure

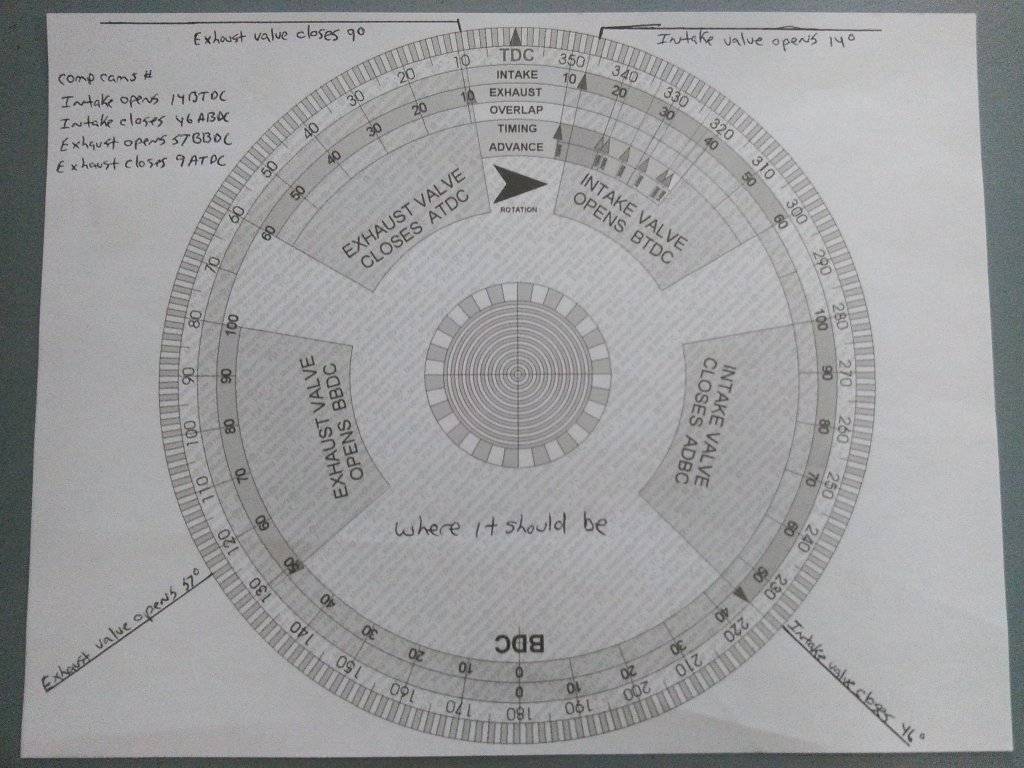

Next picture is where Comp cams is telling me it should be reading using the @ .050 deal

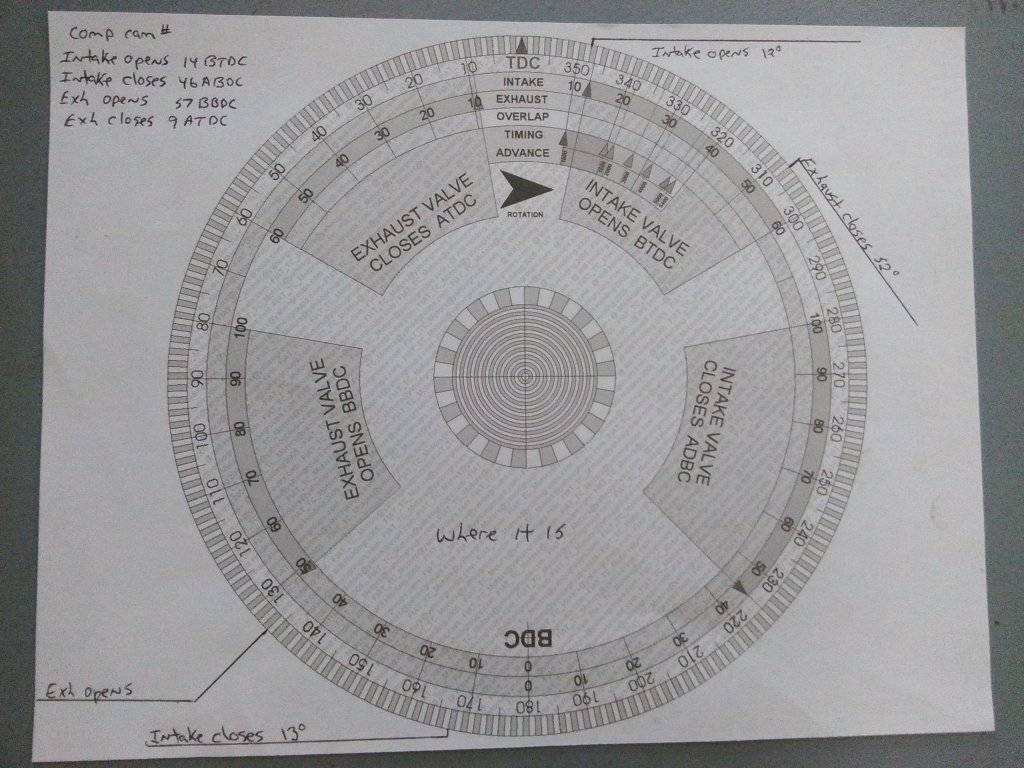

Next picture is what Im getting using the @ .050 deal

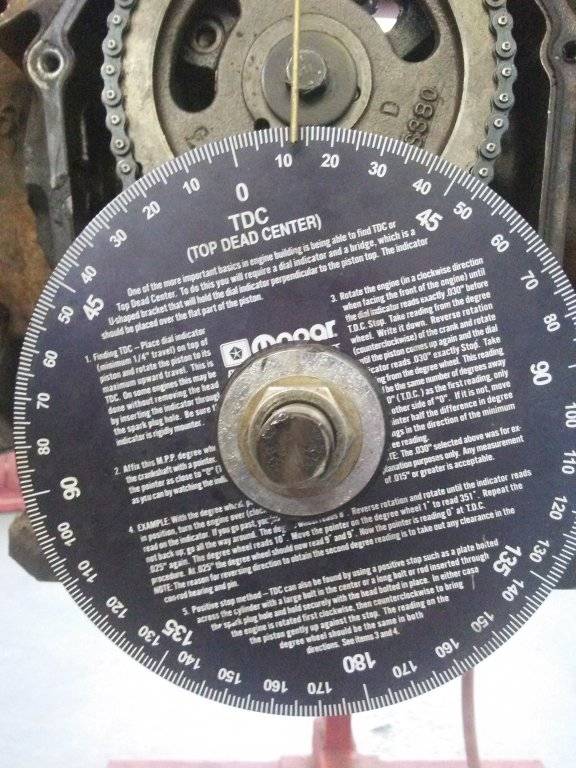

Next picture is just showing my dial indicator set-up

Last picture is showing the intake opening measurement using the @ .050 deal which is about the only measurement that makes any sense

EDIT: Uh cause some knumnuts put the wrong info online

Below is the procedure I am following meticulously. I have tried this same procedure a couple of different times with same results.

First picture is my procedure

Next picture is where Comp cams is telling me it should be reading using the @ .050 deal

Next picture is what Im getting using the @ .050 deal

Next picture is just showing my dial indicator set-up

Last picture is showing the intake opening measurement using the @ .050 deal which is about the only measurement that makes any sense

Last edited: