Ironmike

Well-Known Member

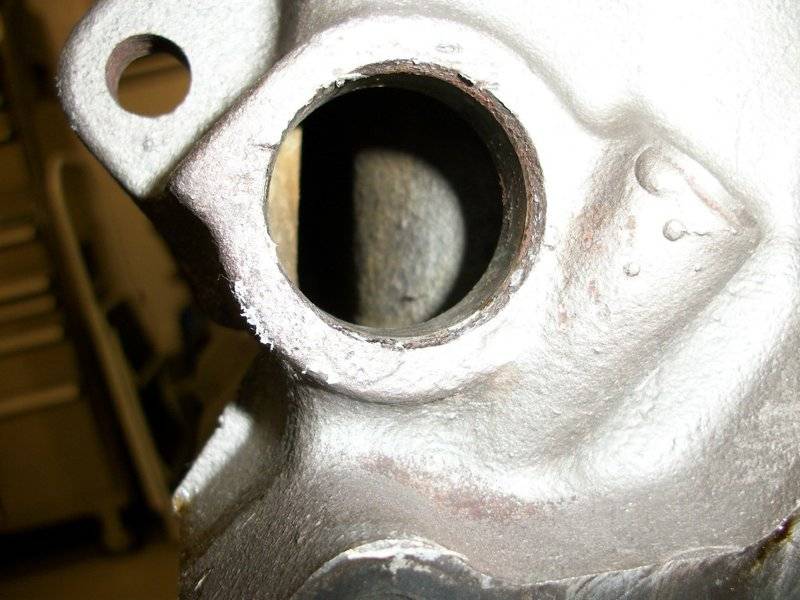

This block I'm working on was one of the ugliest, filthiest things I ever saw. Un-opened factory that was sitting in a damp cellar for 26 years. ....horrible!

of course my machinist tanked it and ran it through his Mart(spelling?) machine, so it cleaned up ok. Something I have been doing now for the 3rd motor may seem like a waste, but I'll fill ya in anyhow. it only cost around 30 bucks to do.

Stop at parts store and buy the cheapest block kit you can that has all the softplugs and such. AND grab a gallon of Evaporust or something similar.

Seal up the old block temporarily with the plugs and fill er up with the de rust stuff. Let soak overnite. Pull all the plugs, drain and rinse.

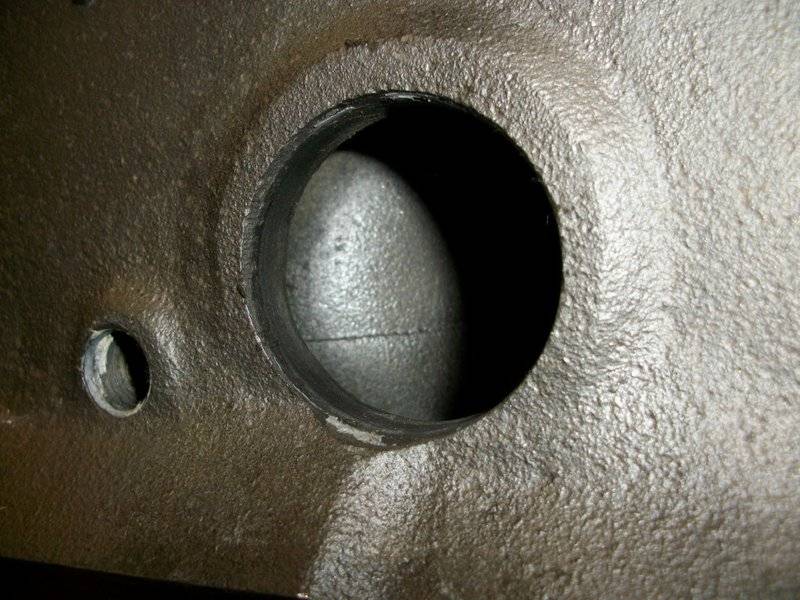

I've been doing this and honest to God my motors run so damn cool it's wierd. and my antifreeze looks brand new.

Might be an anal waste of time, but it sure makes things look nice!

of course my machinist tanked it and ran it through his Mart(spelling?) machine, so it cleaned up ok. Something I have been doing now for the 3rd motor may seem like a waste, but I'll fill ya in anyhow. it only cost around 30 bucks to do.

Stop at parts store and buy the cheapest block kit you can that has all the softplugs and such. AND grab a gallon of Evaporust or something similar.

Seal up the old block temporarily with the plugs and fill er up with the de rust stuff. Let soak overnite. Pull all the plugs, drain and rinse.

I've been doing this and honest to God my motors run so damn cool it's wierd. and my antifreeze looks brand new.

Might be an anal waste of time, but it sure makes things look nice!