moparmatt19

Well-Known Member

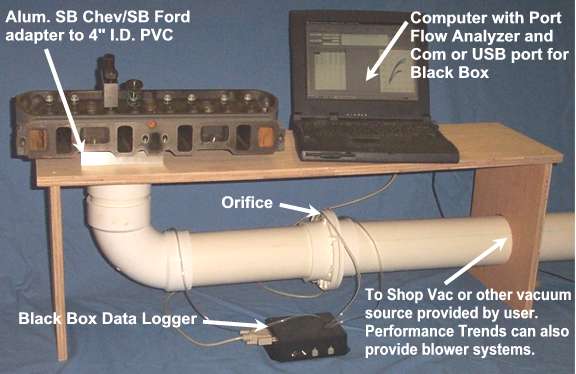

I am wanting to build a flow bench. Has anyone built one? I'm looking into this kit alsohttp://www.flowperformance.com/system.html

You can build a simple "manometer" at home. (manometer is a gauge to sense pressure drop).

determine the sensitivity of your "gauge"..

I`ve been thinking along these lines , just to equalize intake port flow.How many hot rods do I plan to do? Well I hope a lot. I hope to have another good 30 yrs of building left. I have and do build engines for people on the side and would like to have this or something to use to help gain in the process. Also I haven't not had a engine that I was building since high school. Its my hobby, Passion, and been my profession... Not saying I'm any master engine builder or anything , but I do plan to be lol. Take it how ya want. Anyhow I am in the works of starting another shop in Florida in probably 2 years. It will be a full repair shop, but it will also cater to high performance needs also. And eventually years down the road will have a in house machine shop. So not only do I want this for myself but I want this for a tool to work with and make money with later on. $1000 is really not much for a tool. Not saying to flash but to state the fact I've prob spent over $20,000 in tools already in the years I've been doing this. Can't make money without tools. And to get, say a stage 2 port job that most company's offer is around $750 and full port $1,000+ . yes they are experienced in porting , but they did learn and do go by flow numbers on a bench. So if I take a set of junk 915 J's I have and test and learn on them with the flow bench then I can apply that knowledge to my good set and have a nice set of heads. And the cost of paying someone to do it for me that I didn't spend just paid for the flow bench and the next set of J's I do will be free beside my time put in. Not another $750-$1000. So I think its worth it. And also I will be able to see how different valve jobs I grind effect the flow to know what works and what don't. Even if I only do 3 sets of heads ever again and I was able to get them to flow good by using this as a guide, well I think it would be worth the cash.

Anyhow I am interested in looking into this manometer also. And I'm glad you mentioned it. Thank you.