I was trying to find an old post I was reading on how to build and use a piston stop for true TDC. I can't seem to find it. Can someone explain it again or guide me to the post? Thanks........................

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building stop to check TDC

- Thread starter DART66GT

- Start date

-

1969Swinger

Well-Known Member

Set the piston stop so it hits some about before TDC say 20 Degrees make a mark on the harmonic balancer at the 0 Timing point on your degree indicator. Back the engine around the other way till you the other side of TDC, make another mark...right in between them should be exactly TDC. I've also just done it with a piece a wire down the spark plug hole just feeling when it stops coming up...which is kind of redneck but it can get pretty close.

Thanks for the reply. In the old post they said how to build a stop using an old spark plug?

dusterdon

Well-Known Member

All you need is a flat piece of steel or aluminum that has holes for 2 opposing head bolt holes. Directly in the middle drill and tap for a say, 3/8" screw. Put in the screw with a locknut on the outer side and you're done. A nice easy to build but useful tool.

adriver

Blazing Apostle

Knock the ceramic insulator off of and the guts out of a spark plug.

Weld a nut on the base for a piece of all tread or treaded rod to screw into it for your adjustable stop.

Then follow 1969Swingers instructions making the dimension smaller and smaller till your find TDC.

Maybe that makes sense.

No more time tonight.

Happy New Year!

:clock:

Weld a nut on the base for a piece of all tread or treaded rod to screw into it for your adjustable stop.

Then follow 1969Swingers instructions making the dimension smaller and smaller till your find TDC.

Maybe that makes sense.

No more time tonight.

Happy New Year!

:clock:

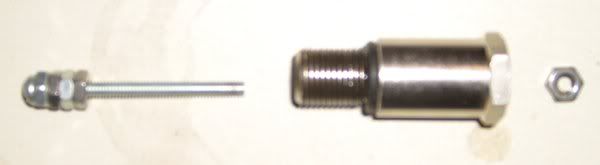

Here is how I made one without welding. You will need a compression tester adapter (a spark plug non-fouler works too) and a screw and some nuts.

You can add or remove nuts till you get it the right length.

I think the screw is a 10-32 about 2" long, though longer would be a bit easier.

This is what it looks like when done

Just make sure the nut you put on the inside is tight. I used this when building my slant and it worked good.

TopHat

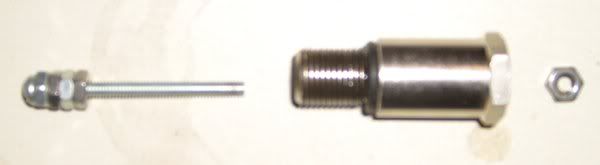

You can add or remove nuts till you get it the right length.

I think the screw is a 10-32 about 2" long, though longer would be a bit easier.

This is what it looks like when done

Just make sure the nut you put on the inside is tight. I used this when building my slant and it worked good.

TopHat

- Joined

- Jun 2, 2004

- Messages

- 5,034

- Reaction score

- 39

Thanks TopHat! Simple, useful, and inexpensive tool... 8)

66dartgt

Well-Known Member

I did something very similar. Knocked the insulator out of a used plug and ground out the insulator side a little and then punched in a 1/4 -20 bolt about 1 1/2" long in it, enough to stick out about 3/4" or so on the combustion chamber side. Then put a nut onto the combustion chamber side of the threads, tighten it down good. Then grind the nut down to the same size as the end of the plug so it can thread into the head. I've had the same tool sitting in my box for 25 years, works fine.

-