retsud_043

Well-Known Member

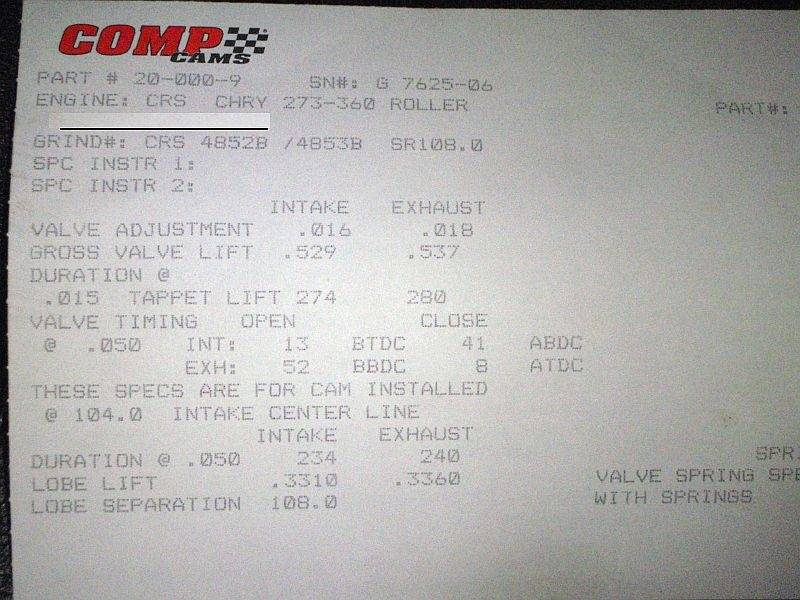

I need your opinion on this camshaft.Its duration at .050 is 234 intake, 240 exhaust. Its lobe lift is .331 intake, .336 exhaust (.529/.537 valve lift with 1.6 ratio rocker arms). It has a lobe separation of 108.

This will be going into a 1970 340 :steel crank, resized 340 rods, 9.5:1 .030 KB pistons, U heads w/ 273 adj. rockers 2.02/1.60, 1970 hi-po 340 exh. manifolds, Edelbrock LD340 intake, 800 TQ, MSD 6a with MSD billit dist.

The engine will be going into a 1971 Duster with an a833 o/d,3.55 8 3/4 489 clutch type sure grip and 26" tall rubber.

This car will be mainly a cruiser but will se the occasonial trip to the track.

Any input on this cam for this application would be appreciated.

Thanks,

Chris

This will be going into a 1970 340 :steel crank, resized 340 rods, 9.5:1 .030 KB pistons, U heads w/ 273 adj. rockers 2.02/1.60, 1970 hi-po 340 exh. manifolds, Edelbrock LD340 intake, 800 TQ, MSD 6a with MSD billit dist.

The engine will be going into a 1971 Duster with an a833 o/d,3.55 8 3/4 489 clutch type sure grip and 26" tall rubber.

This car will be mainly a cruiser but will se the occasonial trip to the track.

Any input on this cam for this application would be appreciated.

Thanks,

Chris