Yeah I knew the pushrods didn't affect the rocker ratio......I was just tryin to hammer on how important is it to measure. ........and it is imperative. But you just cannot tell that to some people.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can I "borrow" rocker arms from my '65 273 for my '71 340?

- Thread starter dibbons

- Start date

-

The actual measurement for adjuster protrusion (taking into account the rockers have the factory oil hole timing) is 9/32" +/- .020 and the more agressive the lobe the more important this is.

Pushrod length does NOT affect rocker arm geometry per se, as the only thing that controls geometry on a shaft is the relationship of the valve to the height of the stand, and the rocker itself. Lift factors in, but en talking about correcting geometry, you either raise or lower the shaft, or make the valve longer or shorter. The push rod length just affects how far out the adjuster is...

The rocker ratio is still the same, but the motion of the pushrod is different. Think of it like jointed pushrod. The farther down the adjuster ball is from the rocker, more it swings away from rocker shaft centerline at max lift.

340dartley

Well-Known Member

- Joined

- Feb 4, 2007

- Messages

- 519

- Reaction score

- 170

I have my original 273 rocker arms on my current 340. I had the pushrods made custom back in 1992 for using a hydraulic cam in my 273. I have since used the same push rods and rockers on 2 other 340s. The fit into each engine without issue. Not saying other people have not had issues. I don't think Chrysler made a whole bunch different standard pushrods for other engines to work with non adjustable. My 273 shaft have the banana grooves in the bottom.

yellow rose

Overnight Sensation

The rocker ratio is still the same, but the motion of the pushrod is different. Think of it like jointed pushrod. The farther down the adjuster ball is from the rocker, more it swings away from rocker shaft centerline at max lift.

Yup, and remember if making the adjuster longer or shorter moves it closer to, or further from the shaft, it is affecting ratio.

dibbons

Well-Known Member

I'm still not ready to assemble the 340. However, I just remembered the 273 rockers and shafts were reconditioned by a place up in Northern California. I will have to pull them out of storage to inspect, but if the rocker arms have bushings now, maybe the shafts won't necessarily need the grooves?When there is no lash, there is not enough clearance and the rocker will gall the shaft.

Hi there,I'm still not ready to assemble the 340. However, I just remembered the 273 rockers and shafts were reconditioned by a place up in Northern California. I will have to pull them out of storage to inspect, but if the rocker arms have bushings now, maybe the shafts won't necessarily need the grooves?

If you had Rocker Arms Unlimited

In California recondition your Rockers and Shafts they probably did cut banana grooves in the shafts if they weren't already.

They recently put bushings in a set for me

And highly recommended grooving the shafts.

Especially with a hydraulic cam.

If their not grooved you can do it yourself carefully with a Cutoff wheel or the like...

Uncle Bob

Shiny paint causes stress.

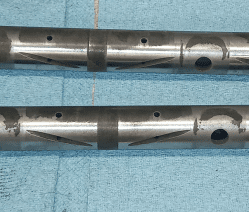

Factory banana groove shafts have two oil holes per cylinder, one is in the groove, the other is a little farther around.

A hydraulic shaft does not.

Also, the direction of the groove alternates.

A hydraulic shaft does not.

Also, the direction of the groove alternates.

ir3333

Well-Known Member

The TA pushrods are the correct length at around 7.25" but they are hard to find. Anything close to that will work

fine..remember they are adjustable. I've never seen an inadequate oil problem using regular shafts?

I think i have a complete set of ball cup pushrods that will work at about 7 5/16".

If interested PM me and i'll check

fine..remember they are adjustable. I've never seen an inadequate oil problem using regular shafts?

I think i have a complete set of ball cup pushrods that will work at about 7 5/16".

If interested PM me and i'll check

Last edited:

-