The late B spindles are the same height as the FMJ spindles, they should not be causing this issue. This is further reinforced by it only being a problem on one side. At least it shouldn't be the design of the spindle, there is of course still the possibility of that particular spindle being mismatched or worn out somehow.

The hotchkis UCA's can be a little tedious to set up. The one's I have on my Challenger, for example, are not set up the same side to side, but the alignment is the same. Remember that even the suspension point tolerances on these cars aren't that great. So, it's possible that your UCA isn't adjusted properly and is at some extreme end of the alignment window. The problem with that of course is that the only way to really know that is set the alignment on the car. It takes some trial and error, unfortunately. When I set my Challenger I made 3 or 4 different trips to the alignment shop. They didn't want to have the liability of adjusting the aftermarket components, and the Hotchkis UCA's have to be removed in order to make adjustments (they aren't double adjustable), so I would make my adjustments and then have it checked. Which is why I've now purchased enough alignment equipment to set my alignment myself.

While the adjustable arms are great for their range of adjustment, I've gone away from recommending them for street cars. The non-adjustable tubular UCA's out there allow for plenty of adjustment with the stock camber bolts because of the additional caster they have built into them. Not only that, but I've found that the heims don't last that long on the street. Hotchkis warrantied my first set after only 7k miles on my Challenger. Granted, I was using the car as a daily driver at the time in all weather conditions, but that still isn't very long. The SPC UCA's I'm putting on my Duster are double adjustable (they don't have to be removed to be adjusted), and they have bushings instead of heims.

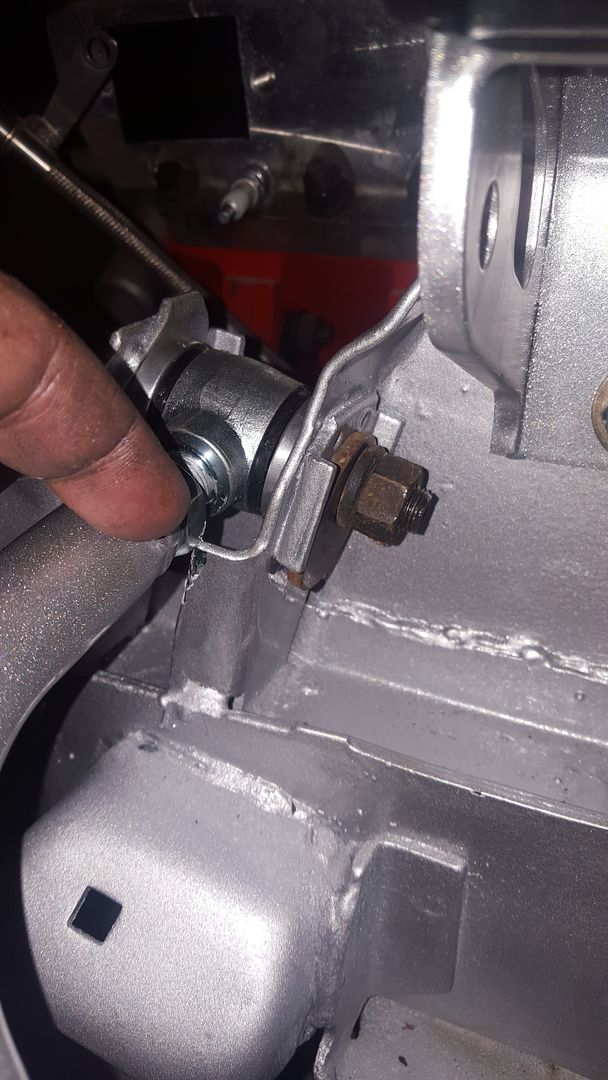

I would rule out all of the suspension components first though, to be sure it's the ball joint and nothing else. At that point I'd assemble everything and put an alignment on the car, and see if it's still an issue with the proper alignment settings. Something else to consider is taller bumpstops. That may seem like a band aid, but again, remember that you're dealing with a lot of aftermarket components here. The bumpstop you're using in the picture may be from Hotchkis, but it also appears to be shorter than the factory bumpstop. If that's the case, you may be overextending the suspension to begin with. I run even taller bumpstops than came from the factory, although that comes from my 1.12" torsion bars and my lowered ride height.