I posted the in the electrical & ignition section a while back you can go here for more info:

Can't get it to idle right!

Basically what have is a '73 340 with J heads, a seemingly wild cam solid lift cam, RPM intake, Eddy AFB 750 (I also used an AVS 625 with no improvement) with an electric choke, a Mr gasket light spring replacing the big one in the stock electronic distributor, Crane 1.5 roller rockers, a Stock mechanical fuel pump (pumping a consistent 5-6 psi)

I haven't had any luck since getting it to stay at a consistent idle!

It seems to do best at when I set the timing 35 deg. total advance.

I've done a compression test and it has 150 psi in all cylinders

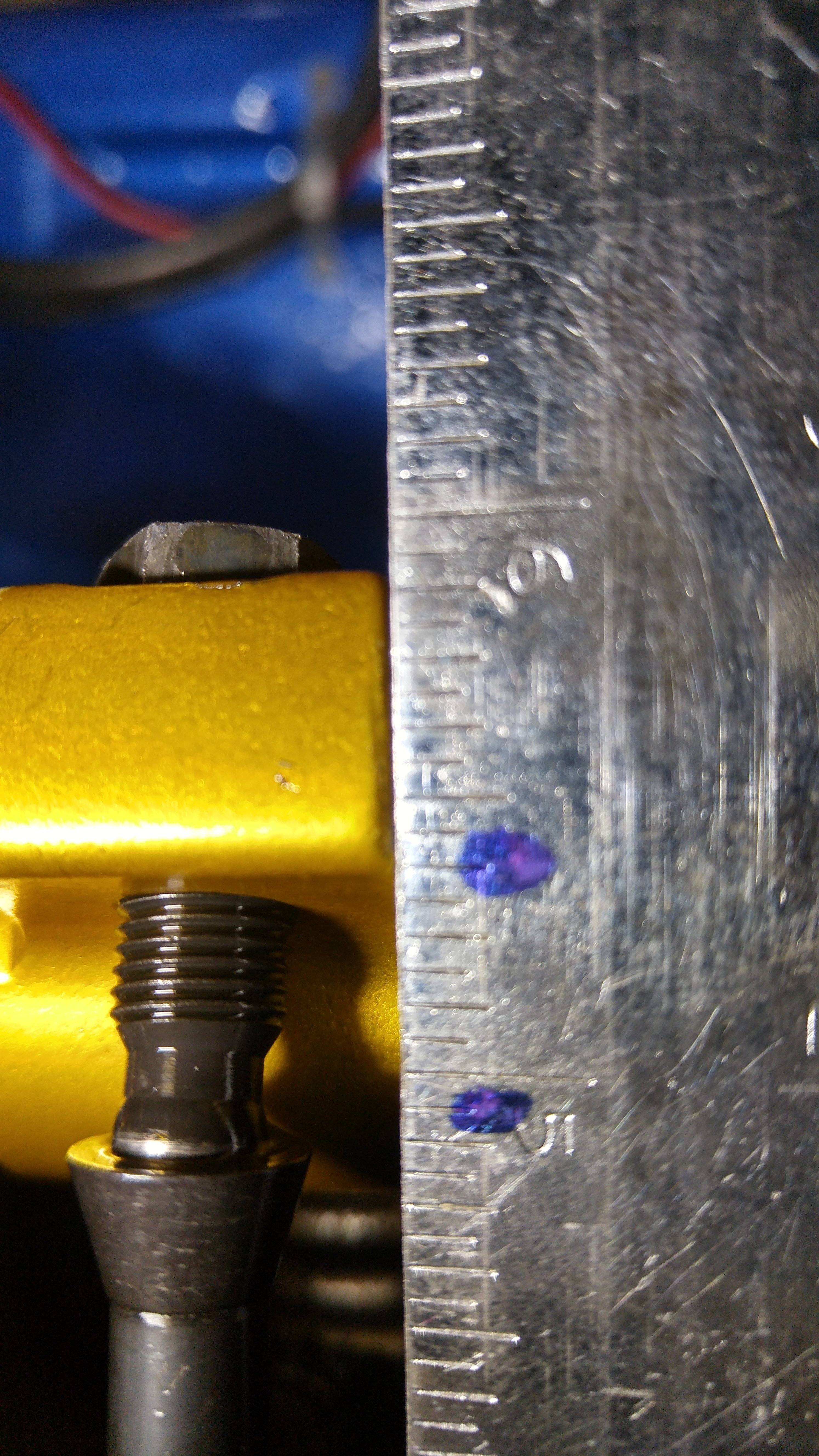

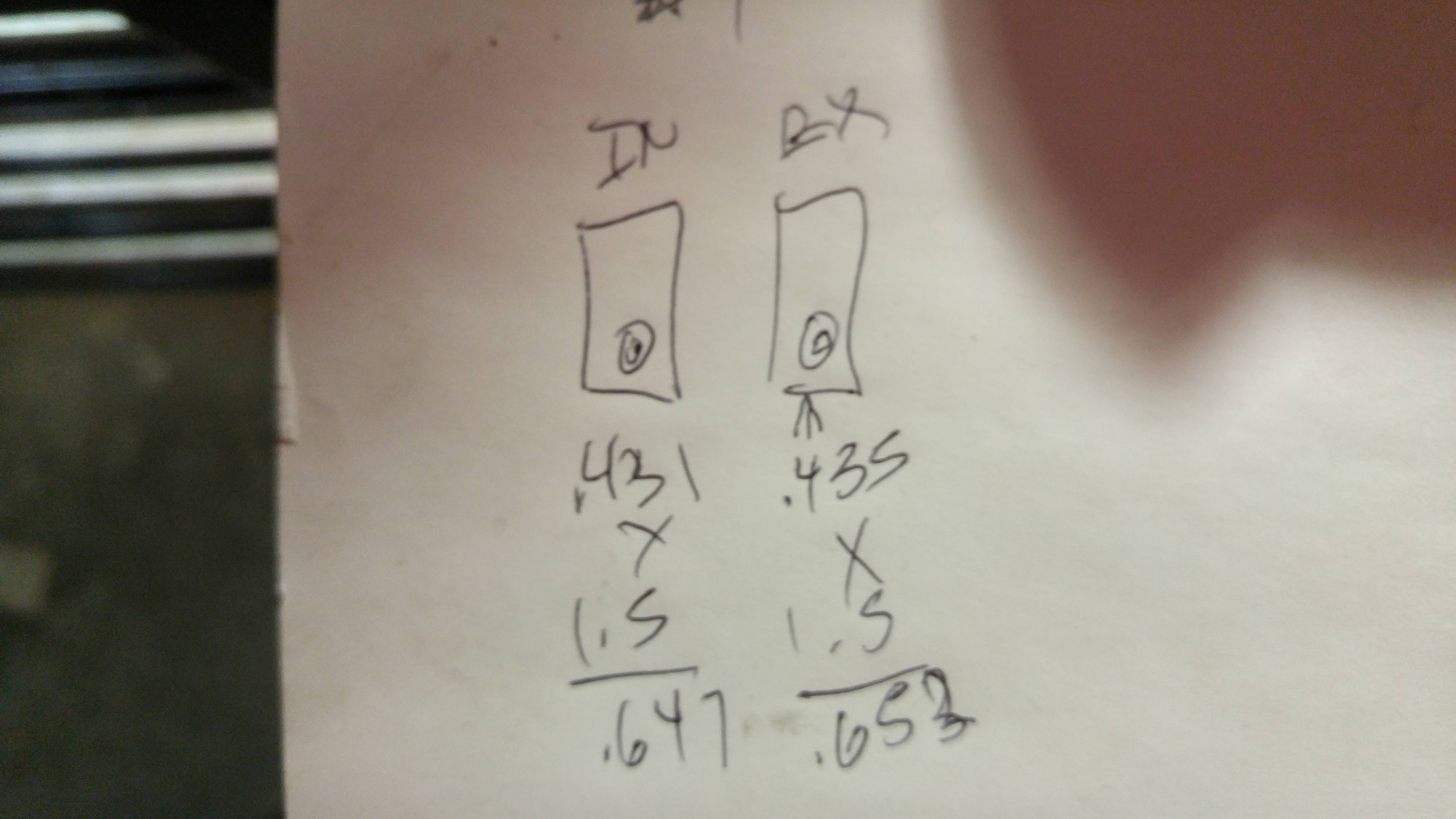

I tried to measure the valve lift with dial indicator, but I could never get a consistent reading so I use a ruler to get a somewhat of a ballpark reading (see pictures). @.647 and intake and .653 exhaust did I calculate this right? If it is how does this engine even run?

Can't get it to idle right!

Basically what have is a '73 340 with J heads, a seemingly wild cam solid lift cam, RPM intake, Eddy AFB 750 (I also used an AVS 625 with no improvement) with an electric choke, a Mr gasket light spring replacing the big one in the stock electronic distributor, Crane 1.5 roller rockers, a Stock mechanical fuel pump (pumping a consistent 5-6 psi)

I haven't had any luck since getting it to stay at a consistent idle!

It seems to do best at when I set the timing 35 deg. total advance.

I've done a compression test and it has 150 psi in all cylinders

I tried to measure the valve lift with dial indicator, but I could never get a consistent reading so I use a ruler to get a somewhat of a ballpark reading (see pictures). @.647 and intake and .653 exhaust did I calculate this right? If it is how does this engine even run?