Cant get this slant 6 to run. Several years ago I bought this 76 Dart Sport to restore. I knew there was something wrong with engine when I got it and figured it was a blown head gasket. We finally got some time to look at it. Long story short, it wasnt head gasket. There was a problem with block. I found another slant 6 out of a 74 Duster. I tore it down, replaced rods and main bearings and re-ringed it. Redone the head and put it all back together. Not knowing anything about this new engine, dist, coil, etc. I used everything off the original engine. The original engine ran good except for smoking some out the exhaust. I suspected antifreeze out the exhaust but it started fine, ran. Rebuilt this new engine with new rod and main bearing and rings. Before I put the head on I got No.1 piston up TDC and marked the damper pulley. Rotor pointing at no. 1 plug wire on dist.Tried to start engine and it just turns over. Pulled plug wire off no.1 plug and there is no arc when trying to start. So far we replaced ECM and ballast resistor. Coil is the same as the engine that was running before we pulled it down. Checked wiring and nothing seems to be broken. I am not a mechanic, but I do know enough to work on these. I did the same thing a few years ago with my 69 slant 6 and it fired right up. I dont know where else to go with this. But it doesnt seem to be getting fire to the plugs.Dist cap, rotor, plug wires, coil are all fairly new. Any help would be appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cant get this to run, need help

- Thread starter trudysduster

- Start date

-

OK to start make sure you have power in and out of the ballast resistor. Start there we will get you going.

Before I put the head on I got No.1 piston up TDC and marked the damper pulley. Rotor pointing at no. 1 plug wire on dist..

^^^This^^^OK to start make sure you have power in and out of the ballast resistor. Start there we will get you going.

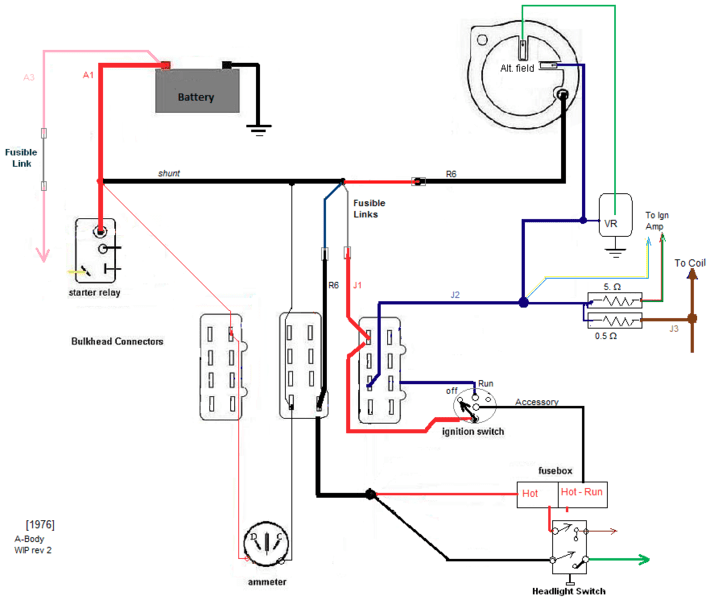

Also if you aren't already aware, '76 power feeds were wired differently than early cars. Ignition is the same.

Do it two stages. Battery fully charged.

1. Put the key in run and measure voltage at all four terminal postions on the ballast (assuming its factory dual ballast).

If there is a break in either of the ballast. Stop there.

2. With a helper, measure the voltage on the coil side (J3 in drawing below) of the ignition with the key held in Start.

Work in progress. According to the diagram in the service manual, wire J2E in the diagram above that powers the ECU in 1976 comes from a welded splice. That doesn't change the test, just the wires you will observe at the ballast resistor.

MOPAROFFICIAL

Oogliboogli

As said test power in and out of ballast, check/test or try diff ignition box.

Resistance check the coil, google the coil to find out resistance, probably around 10k.

You're missing power or trigger in the ignition system.

Resistance check the coil, google the coil to find out resistance, probably around 10k.

You're missing power or trigger in the ignition system.

67Dart273

Well-Known Member

CHECK SPARK OUT OF THE COIL AND DO NOT USE the factory coil wire. This is because "most" wires are still resistive wires and can fail internally. "Rig" a spark gap (like a plug) and you can use low voltage wire if you "dangle" it away from ground points.

TURN KEY to "run." Check voltage at coil+ It should be quite below battery voltage, perhaps 6-8 V and certainly not less than about 5 or 6 and certainly no more than say, 10. THIS TEST shows that the coil is getting power through the ballast resistor AND THAT the ECU is causing it to draw current

WITH THE key still in "run" pull the dist trigger wire apart and take the engine harness end of the connector. Repeatedly ground the bare terminal of the connector. Each time should produce one "SNAP" blue hot spark at your coil test gap

TURN KEY to "run." Check voltage at coil+ It should be quite below battery voltage, perhaps 6-8 V and certainly not less than about 5 or 6 and certainly no more than say, 10. THIS TEST shows that the coil is getting power through the ballast resistor AND THAT the ECU is causing it to draw current

WITH THE key still in "run" pull the dist trigger wire apart and take the engine harness end of the connector. Repeatedly ground the bare terminal of the connector. Each time should produce one "SNAP" blue hot spark at your coil test gap

CHECK SPARK OUT OF THE COIL AND DO NOT USE the factory coil wire. This is because "most" wires are still resistive wires and can fail internally. "Rig" a spark gap (like a plug) and you can use low voltage wire if you "dangle" it away from ground points.

TURN KEY to "run." Check voltage at coil+ It should be quite below battery voltage, perhaps 6-8 V and certainly not less than about 5 or 6 and certainly no more than say, 10. THIS TEST shows that the coil is getting power through the ballast resistor AND THAT the ECU is causing it to draw current

WITH THE key still in "run" pull the dist trigger wire apart and take the engine harness end of the connector. Repeatedly ground the bare terminal of the connector. Each time should produce one "SNAP" blue hot spark at your coil test gap

ok, it may be later this week but I will get to this and try these. Someone said that the timing is 180 out. is that possible. what blows my mind is that this car ran when we drove it in the garage to pull the engine. Used the same parts off the old motor. so what changed.

Even if it's 180 out, it should at least pop in the exhaust and maybe the intake.ok, it may be later this week but I will get to this and try these. Someone said that the timing is 180 out. is that possible. what blows my mind is that this car ran when we drove it in the garage to pull the engine. Used the same parts off the old motor. so what changed.

Even if it's 180 out, it should at least pop in the exhaust and maybe the intake.

ok, will be able to check this out later this week. thanks

TT5.9mag

Two atmospheres are better than one

You do know there are 2 TDCs on number one right? TDC compression and TDC on exhaust stroke. If you stabbed the distributor while at TDC on exhaust it will be 180 out. Easy way to tell, ignore where the rotor is, pull number one plug and rotate engine with your finger in the plug hole. You’ll feel the compression when it makes it. Look for the timing mark. Possibly not the one you made. Continue to rotate until the timing mark comes up near “0” on the timing cover. Now look at the rotor and see where it’s pointing. Should be at whichever terminal you have number 1 plug wire on.

67Dart273

Well-Known Member

Unless there's no spark, there's no fuel, OR THE FUEL is old and stale.Even if it's 180 out, it should at least pop in the exhaust and maybe the intake.

Pull no1 plug. Devise a way to test compression. (I don't think? you can get your finger that deep on a slant? Screw in the compression tester. Bump the engine until you start to get compression. Bring the marks up to "where you want" timing AKA 5 or 8BTC or wherever. Pull the cap, the rotor should just be approaching "at" the no1 plug tower. You can also use a timing lite "on the starter"

Right. Well, you know me. I was taking for granted "that part" was known. lolUnless there's no spark, there's no fuel, OR THE FUEL is old and stale.

Pull no1 plug. Devise a way to test compression. (I don't think? you can get your finger that deep on a slant? Screw in the compression tester. Bump the engine until you start to get compression. Bring the marks up to "where you want" timing AKA 5 or 8BTC or wherever. Pull the cap, the rotor should just be approaching "at" the no1 plug tower. You can also use a timing lite "on the starter"

OP stated no spark so lets get that fixed first for him

OP stated no spark so lets get that fixed first for him

View attachment 1715925631

I apologize for not getting back on this for so long. Shortly after I started this thread I became sick. Something hit me like a ton of bricks. I think it may have been Covid. Not sure. I finally got back to the garage and took some readings. With the key on, looking at the ballast resistor from the front of the car. I have 10.9 v on top right terminal of ballast resistor, 10.9 on top left term, 10.6 on bottom left term and 5.4 on bottom right term. I took a reading on + term. of coil and it looks like 4.7 v. Not been able to do much more but does this help. This is a new ballast resistor. I have a new coil if needed. I have not been into this lately but wanted to get back to you on this. Thanks,Bill

67Dart273

Well-Known Member

Those readings are not bad except the highest ones. The one feed from the key should be very near "same as battery" (so check that against battery, is it down?) If the battery is "up at 12.2 or so then that 10X should be 12.X That low voltage will also cause overcharging when running. Most likely suspects is the "path" from battery through fuse link, through bulkhead/ ammeter circuit, to the IGNITION SWITCH CONNECTOR, through the SWITCH, back out the SWITCH CONNECTOR and back out the BULKHEAD CONNECTOR on the ignition feed, IGN1

You want to also connect to coil+ and check that to ground WHEN CRANKING to see what it is doing. Should be "same as" battery when cranking.

You want to also connect to coil+ and check that to ground WHEN CRANKING to see what it is doing. Should be "same as" battery when cranking.

Or the battery is low.

To be clear, should be "same as" battery when cranking means taking a battery voltage reading while cranking.

Same with your 10.9 Voltage readings with key in run. Take a voltage reading of the battery with the key in run.

This is neccessary because battery voltage drops when there is a load on it. How much it drops depends on the load, the battery capacity, and its state of charge.

To be clear, should be "same as" battery when cranking means taking a battery voltage reading while cranking.

Same with your 10.9 Voltage readings with key in run. Take a voltage reading of the battery with the key in run.

This is neccessary because battery voltage drops when there is a load on it. How much it drops depends on the load, the battery capacity, and its state of charge.

67Dart273

Well-Known Member

I thought I said that. YES WHAT I meant was when I say "same as battery" is not some figure "12 v" I mean it should be "same as what the battery is actually reading." And if the battery is low, do something with that, charge it, test it replace it etc.

You must also understand "a bit" how this works.

Ballast resistor voltage (ANY resistor) is dependent on the load THROUGH it. So with the key "in run" the coil draws current and causes the coil connection to DROP in voltage. Normal. But you need "same as battery" getting TO the resistor and you don't

BUT THAT IS THE RUN circuit, NOT the start circuit

When you twist the key to start, the IGN2 "bypass" circuit comes into play. If you read earlier I talked about checking for spark, I specified "while using the key" to crank. This is important.

If something is wrong with the bypass circuit, the ign. system will not get any/ adequate voltage to start

THE RUN (IGN1) circuit GOES DEAD during "start." The ONLY source if IGN system power for starting is the IGN2 "bypass" circuit. This is a separate wire, comes off a separate contact from the key, and to the coil + side of the ballast

With your meter on coil+ and ground, and twist to start, the coil+ should read "same as battery."

You must also understand "a bit" how this works.

Ballast resistor voltage (ANY resistor) is dependent on the load THROUGH it. So with the key "in run" the coil draws current and causes the coil connection to DROP in voltage. Normal. But you need "same as battery" getting TO the resistor and you don't

BUT THAT IS THE RUN circuit, NOT the start circuit

When you twist the key to start, the IGN2 "bypass" circuit comes into play. If you read earlier I talked about checking for spark, I specified "while using the key" to crank. This is important.

If something is wrong with the bypass circuit, the ign. system will not get any/ adequate voltage to start

THE RUN (IGN1) circuit GOES DEAD during "start." The ONLY source if IGN system power for starting is the IGN2 "bypass" circuit. This is a separate wire, comes off a separate contact from the key, and to the coil + side of the ballast

With your meter on coil+ and ground, and twist to start, the coil+ should read "same as battery."

I thought I said that. YES WHAT I meant was when I say "same as battery" is not some figure "12 v" I mean it should be "same as what the battery is actually reading." And if the battery is low, do something with that, charge it, test it replace it etc.

You must also understand "a bit" how this works.

Ballast resistor voltage (ANY resistor) is dependent on the load THROUGH it. So with the key "in run" the coil draws current and causes the coil connection to DROP in voltage. Normal. But you need "same as battery" getting TO the resistor and you don't

BUT THAT IS THE RUN circuit, NOT the start circuit

When you twist the key to start, the IGN2 "bypass" circuit comes into play. If you read earlier I talked about checking for spark, I specified "while using the key" to crank. This is important.

If something is wrong with the bypass circuit, the ign. system will not get any/ adequate voltage to start

THE RUN (IGN1) circuit GOES DEAD during "start." The ONLY source if IGN system power for starting is the IGN2 "bypass" circuit. This is a separate wire, comes off a separate contact from the key, and to the coil + side of the ballast

With your meter on coil+ and ground, and twist to start, the coil+ should read "same as battery."

Yes, the battery is probably low. we were trying to get this to run when I took sick. I will charge this back up and check this again but if I am getting 12 v to the coil+ then I should be getting spark to the plugs right.

OK to start make sure you have power in and out of the ballast resistor. Start there we will get you going.

Well, I do have power in and out of resistor. voltage on coil + is a little over 5Volts. I changed rotor button, no change. I ran a wire from battery + to coil + and it wouldnt start. I took off #1 plug wire and layed it close to plug tried to start it and there was no arc. I still dont think I am getting fire to plugs. I changed out the coil with a new one , no change. I have been sick, feeling better now and I have had to finish up this corvette and it left last night but this weekend I am going to get busy on this car and see if it will run. I bought a compression tester. I am going to get # 1 up on compression, check timing and make sure dist. is on #1 and try it again. I just dont understand how we can drive this car in the garage, pull engine out, do mains and rod bearings and rings and put it back in and it will not run.Did not change any electrical components.Did not mess with any electrical and not get any fire to plugs now. It must be something stupid.

And I am sure the /6 is grounded to your firewall/chassis.

I seen that happen when changing engines

Carry on, you have some of the best help jumping in here

Good luck

I seen that happen when changing engines

Carry on, you have some of the best help jumping in here

Good luck

I do know that there is a cable running from the firewall to the engine. I made sur it was grounded real good on the engine side when we put the engine back in but I have not messed with the firewall side yet. That is something I am going to check this weekend. I am spending this weekend strickly on this Dart. Customers cars will have to wait.thanksAnd I am sure the /6 is grounded to your firewall/chassis.

I seen that happen when changing engines

Carry on, you have some of the best help jumping in here

Good luck

Charrlie_S

Well-Known Member

Stupid question. Is the two wire plug from the distributer connected to the harness? If yes, make sure the battery is charged up, recheck the voltage at the coil + (it should be more then 5 volts with ign sw on, but not cranking). If voltage is around 8 volts (or higher), connect test light to coil (-), and crank engine. Test light should "blink" on and off. That will tell you if the dist is sending a signal to the module and the module to the coil. If the test light does not blink, it could be a bad module, or bad pickup in the dist.

Last edited:

-