blue missile

Well-Known Member

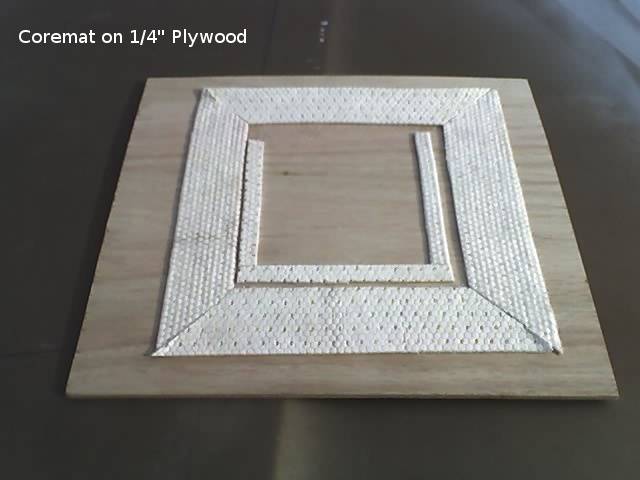

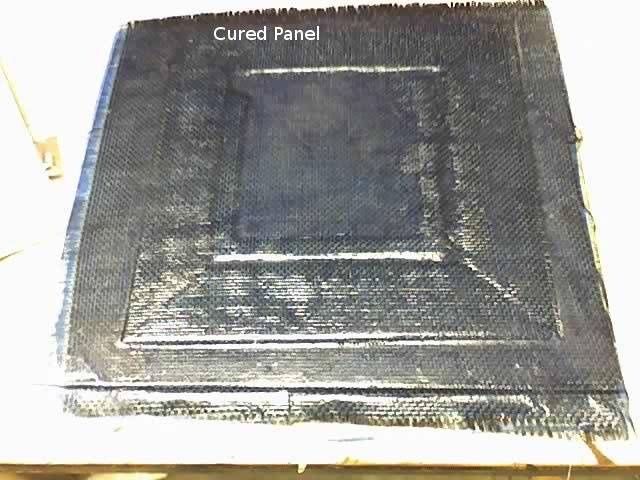

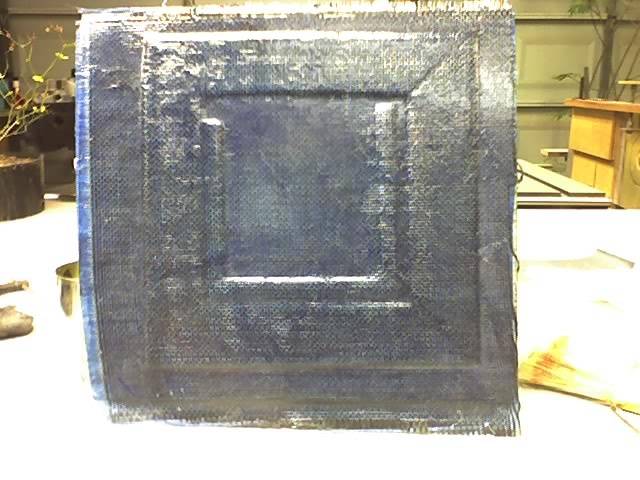

My next project will be putting together the interior panels which would be the door and rear side panels. I may also do the sail panels in a similar fashon. I wanted to give the panels an upolstered look with an eye twoard the original design of the panels. I put together a test panel of 1/4" ply and a lofting fabric called Coremat. I covered the panel with carbon/S glass fabric, I used a clear blue dye for the resin to simulate blue Kevlar which is kind of pricey. I also put up a small sample of carbon/Blue Kevlar that I had to compare the end results.

The blue dye turned out kind of blotchey, and made the panel very blue, verses the real thing which is much more suttle. I'm not sure I want that much blue in the color scheme. It was goiing to be an all black interior with the exception of white bucket seats. The first pic is of carbon/Blue Kevlar

Opinions?

Andrew

The blue dye turned out kind of blotchey, and made the panel very blue, verses the real thing which is much more suttle. I'm not sure I want that much blue in the color scheme. It was goiing to be an all black interior with the exception of white bucket seats. The first pic is of carbon/Blue Kevlar

Opinions?

Andrew