That can be repaired by brazing no problem. But it will look ugly. I personally would get a refund. But like said if u need the passenger side that is harder to get u have options. Kim

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

cast iron repair ?

- Thread starter el5dart

- Start date

-

I would not repair the cast iron, it will come back to haunt you.

I know cast iron can be successfully repaired, but it takes someone who knows what they are doing. It involves pre-heating, then using the correct rods, then properly and slowly cooling. It's not like this can't be done, but it's not a beginner kind of a thing. If you can get a refund I'd go that direction.

el5dart

Well-Known Member

as of now he said he is going to go to his parents house and see if he has another one to replace it. must have a big mopar horde up there.

Kendog 170

Let the boy go !

My friend gave me his manifolds in the 80's . Right side was badly cracked and repaired . I've never had an issue.

el5dart

Well-Known Member

My friend gave me his manifolds in the 80's . Right side was badly cracked and repaired . I've never had an issue.

do you know how it was repaired? mig, tig, stick, braised ?

moparmat2000

Well-Known Member

Wow, that sucks. Yes after welding, you will need to resurface it. I have seen videos online for a process called muggyweld. They have different rods for different materials. I believe in one of the vids they welded a plate over a hole in a cast iron tractor block where a connecting rod let go. The part has to be notched out where the weld goes. I think they pre heat it and use a torch with mapp gas to feed the muggyweld rod in.

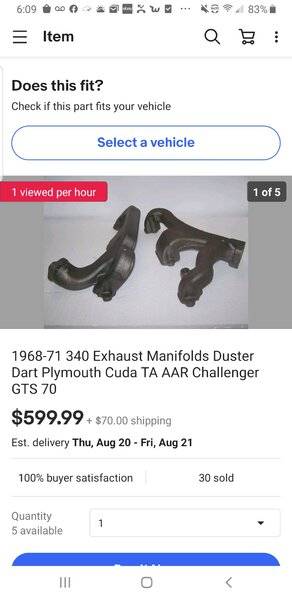

I dunno what you payed for em but I was kinda thinking of going this direction in pic below and just buy new ones since I dont need casting numbers and date codes, plus unless the seller is honest, and you can inspect them personally it's kinda a crapshoot.

I dunno what you payed for em but I was kinda thinking of going this direction in pic below and just buy new ones since I dont need casting numbers and date codes, plus unless the seller is honest, and you can inspect them personally it's kinda a crapshoot.

Kendog 170

Let the boy go !

It was brazed. I got them that way.

Nickel Rod welding of cast iron is one of the better repairs but still a repair.

You have to wonder why they cracked at the outter eyes in the first place. I would say someone locked them down with bolts and none of the oval slide washers. Over tightened not being allowed to slide on the head as the expand and contract through the heat cycle.

They need to be installed with the Mopar slide washers at the specific torque from the mopar books. The torque is not very much because they need to be able to move on the heads or they will crack if over tightened.

Prime example is the slant 6 exhaust manifolds that crack all the time because people over tighten the mounting bolts.

You have to wonder why they cracked at the outter eyes in the first place. I would say someone locked them down with bolts and none of the oval slide washers. Over tightened not being allowed to slide on the head as the expand and contract through the heat cycle.

They need to be installed with the Mopar slide washers at the specific torque from the mopar books. The torque is not very much because they need to be able to move on the heads or they will crack if over tightened.

Prime example is the slant 6 exhaust manifolds that crack all the time because people over tighten the mounting bolts.

For repair yes the choices are brazing or welding - and stick (arc) is generally the process.

But just as important is the very slow heating and cooling of the entire piece before and after welding.

The tricky part with this particular crack is that it runs into a sealing surface; and one that was meant to be a metal to metal seal.

IF you decide to keep it - To find someone who can do it, start calling or driving around. You'll probably get a range of prices and answers. When you find the answer and price that match, then go there.

But just as important is the very slow heating and cooling of the entire piece before and after welding.

The tricky part with this particular crack is that it runs into a sealing surface; and one that was meant to be a metal to metal seal.

IF you decide to keep it - To find someone who can do it, start calling or driving around. You'll probably get a range of prices and answers. When you find the answer and price that match, then go there.

6PakBee

Well-Known Member

Just throwing this out there..... http://www.crownalloys.com/TechSheet/CAST_IRON_ROYAL_44-30_WITH_New_Warning_(White)_PWP.pdf

mopowers

Well-Known Member

I would contact ebay for a refund before touching them with any grinder or welding rod. Provided with the photos and the words in the seller's add, I'd almost guarantee they'll issue a refund. If not, do it through paypal. No way would I mess with trying to repair something that I bought that was supposed to be usable as-is. Either way, good luck!

pishta

I know I'm right....

muggy weld need to get the part hot enough to melt the stick. get a big torch and a rosebud. Dont melt the stick or it will just drip off. Id also torque it down first then weld it. Actually Id just get a free replacement!!!

el5dart

Well-Known Member

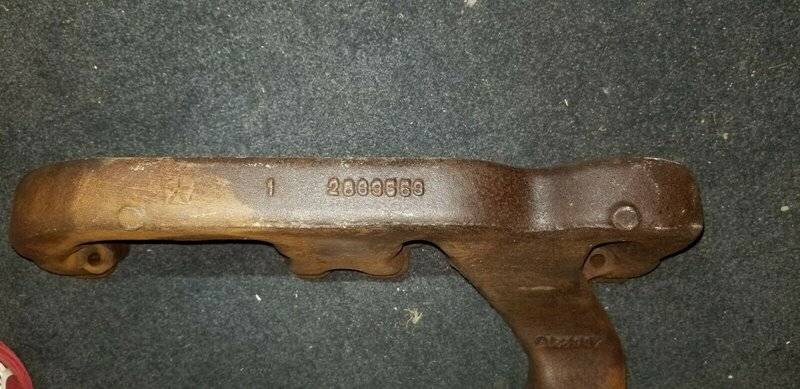

so my depression over this is hopefully going to be lifted. this guy is amazing me by actually having another manifold to exchange the cracked one with. he sent me some pictures of the replacement and I would like more eyes than mine to looksee if you can spot any cracks. he told me the number 5 has a casting flaw and is not a crack. anyways check out the pics and help me vet the reeplacement. THANKS GUYS!!

el5dart

Well-Known Member

more

That looks better.

el5dart

Well-Known Member

i am getting excited. as soon as i get the replacement manifold the motor and trans will be ready to drop the body on it.

-