billytuffnuts

Well-Known Member

I had some issues with my 60 amp denso alternator with being able to put out enough power when my electric fan was running, especially at idle. The fan was pretty loud and you could hear the rpms drop at stop, similar to the common issue of headlights dimming at idle. Idle @ ~900 RPM (mild cam) voltage was around 12.5-13 volts without fans/headlights and about 13.5 at 2000+ RPM

Anyways the alternator bench tested good (autozone) so I decided to upgrade to a 170 amp version and 4awg B+ cable thinking the 60 amp just didn't have enough to keep the fan powered at idle. The test report I received with the alternator states it puts out 80 amps at 833 rpms.

I Hooked everything up and I'm still having the same issue, except at 2000+ RPM the battery voltage increased to 14.5 volts. I've also checked voltage at the alternator B+ terminal with similar values so I don't think its a voltage drop issue.

I've also had the battery tested which was deemed "Good" although they mentioned it's "towards the end of its life. Sounds suspicious.

In addition to the battery I'm also wondering about the engine pulleys: Using March underdrive pulleys on the water pump, crankshaft, and P/S pump - but not on the alternator itself.

Any thoughts on what I might be missing here?

Anyways the alternator bench tested good (autozone) so I decided to upgrade to a 170 amp version and 4awg B+ cable thinking the 60 amp just didn't have enough to keep the fan powered at idle. The test report I received with the alternator states it puts out 80 amps at 833 rpms.

I Hooked everything up and I'm still having the same issue, except at 2000+ RPM the battery voltage increased to 14.5 volts. I've also checked voltage at the alternator B+ terminal with similar values so I don't think its a voltage drop issue.

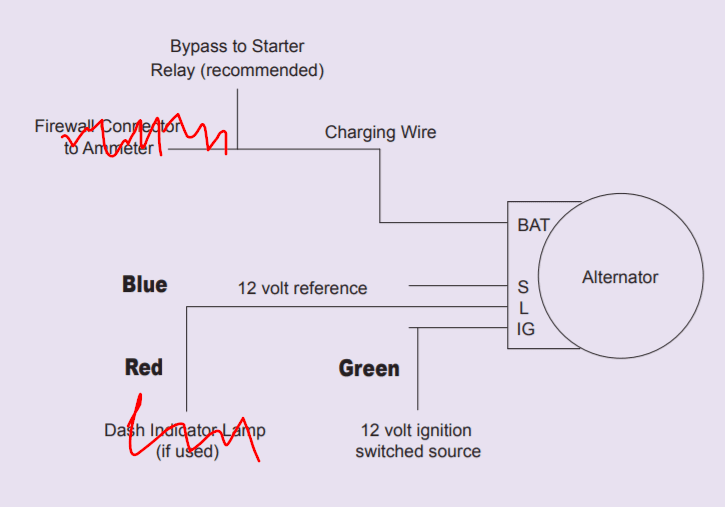

- Sense wire to Starter Relay B+ terminal

- Switched 12v IGN spliced to Electric Choke wire

- Lamp - Not used

- Ammeter Bypassed

I've also had the battery tested which was deemed "Good" although they mentioned it's "towards the end of its life. Sounds suspicious.

In addition to the battery I'm also wondering about the engine pulleys: Using March underdrive pulleys on the water pump, crankshaft, and P/S pump - but not on the alternator itself.

Any thoughts on what I might be missing here?