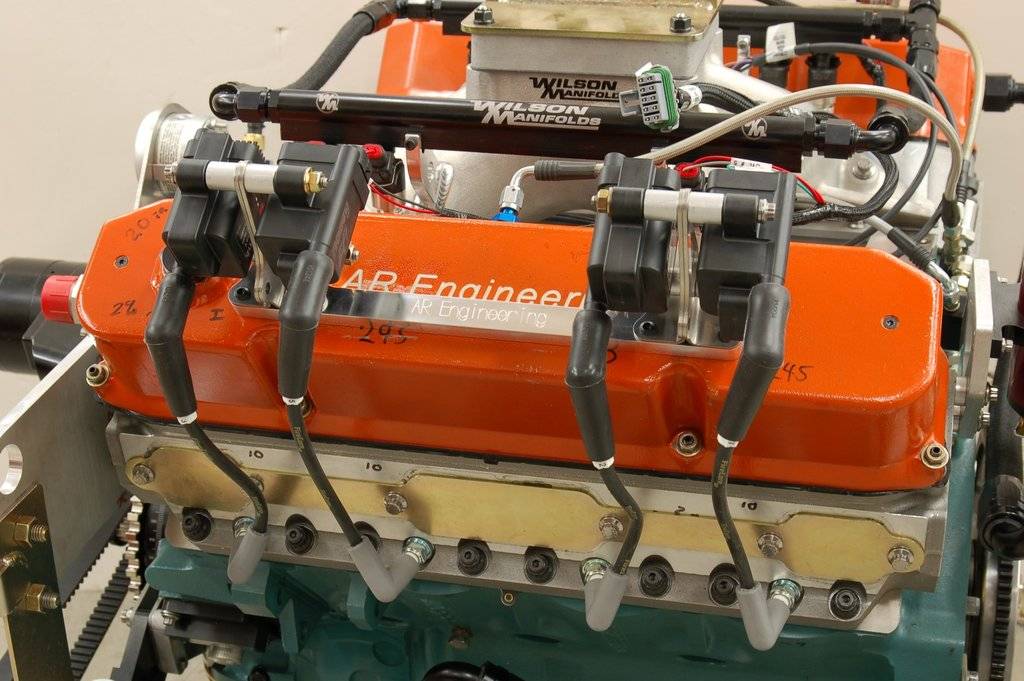

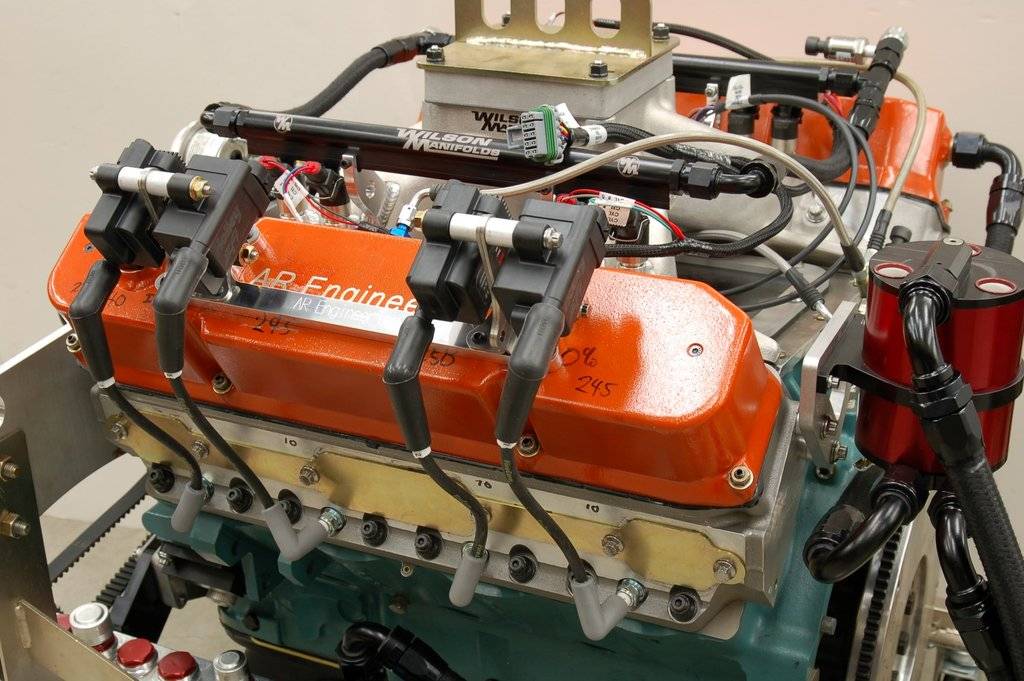

Just finished up the first set of brackets to hang smart coils above the plugs on a big block. This will allow me to get rid of the big MSD 7AL box as well as the MSD coil and the Jesel distributor. I've heard that the engines run a lot better with CnP, guess I'll find out shortly.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CnP (coil near plug) for big blocks

- Thread starter AndyF

- Start date

-

383Duster

Well-Known Member

Crank trigger I presume? What are you using for a control box?

rustycowll69

Well-Known Member

Very interesting. Curious how they will work.Just finished up the first set of brackets to hang smart coils above the plugs on a big block. This will allow me to get rid of the big MSD 7AL box as well as the MSD coil and the Jesel distributor. I've heard that the engines run a lot better with CnP, guess I'll find out shortly.

View attachment 1715060411

View attachment 1715060412

I like your brass exhaust port cover plates. I made something similar about 40 yrs ago. I made mine out of 1/4 SS plate, but yours are much more elegant.

joeboy

Well-Known Member

Very cool. Should give you much better control... Please more about your set up msd? fast?

Awesomely. more reliable... People...don't know primary - secondary spark reserve..Never seen it , like this...Subscription....Just finished up the first set of brackets to hang smart coils above the plugs on a big block. This will allow me to get rid of the big MSD 7AL box as well as the MSD coil and the Jesel distributor. I've heard that the engines run a lot better with CnP, guess I'll find out shortly.

View attachment 1715060411

View attachment 1715060412

Just finished up the first set of brackets to hang smart coils above the plugs on a big block. This will allow me to get rid of the big MSD 7AL box as well as the MSD coil and the Jesel distributor. I've heard that the engines run a lot better with CnP, guess I'll find out shortly.

View attachment 1715060411

View attachment 1715060412

Andy i see you are doing all this cool stuff with newer efi tech. Have you tested Edelbrock's Proflo intake on a RB? Ive wondered if it would be a good intake on an engine like the one you are working on.

Intake Manifolds - Chrysler - Big-Block - Pro-Flo XT Series - Edelbrock, LLC.

Crank trigger I presume? What are you using for a control box?

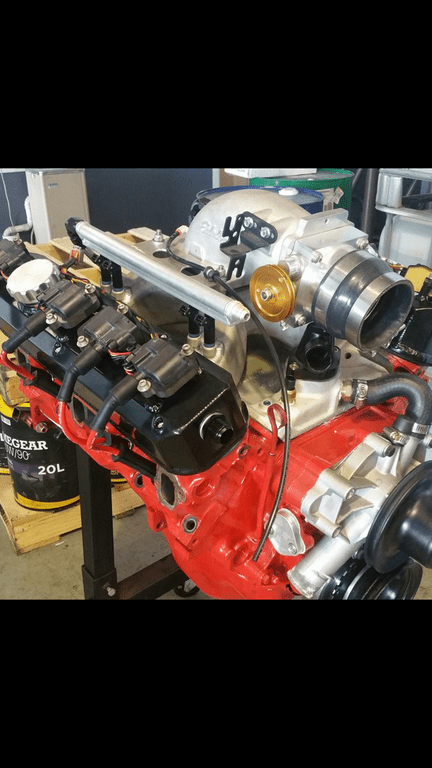

Yes I'm running a 36-1 trigger wheel with a Hall effect sensor. Control box is a Holley HP EFI system. I went with the complete Holley HP universal EFI kit with the 4500 flange throttle body. You can get the kit from Summit. I had to make my own trigger wheel though since nobody makes them for Mopar engines. Here is a picture:

Andy i see you are doing all this cool stuff with newer efi tech. Have you tested Edelbrock's Proflo intake on a RB? Ive wondered if it would be a good intake on an engine like the one you are working on.

Intake Manifolds - Chrysler - Big-Block - Pro-Flo XT Series - Edelbrock, LLC.

I've owned a couple of the ProFlo intakes but I've never used one on an engine. Whenever I buy them and test fit them I decide against using them. They are big and clunky with small ports and a bunch of odd fittings. I bet they work just fine but I can't bring myself to use one! I had Wilson port a Super Victor and then add the bungs. It cam out super nice and it flows a ton of air.

Holley HP kit 550-501 is what I used with 66 lb/hour injectors. Makes 900 hp @ 7000 rpm on race gas. I originally tried to use the Holley dual sync distributor but it didn't fit with my Indy heads so I made my own cam sync unit. Here is a picture:Very cool. Should give you much better control... Please more about your set up msd? fast?

383Duster

Well-Known Member

Very nice work and it is shown in the results.

mopar65

Well-Known Member

Andy that is a cool looking set up you made. Do you plan on making a set up like that for small blocks? I am going with CNP on my magnum 360 build. What you made would save me from having to drill a bunch of holes in my valve covers. Lol

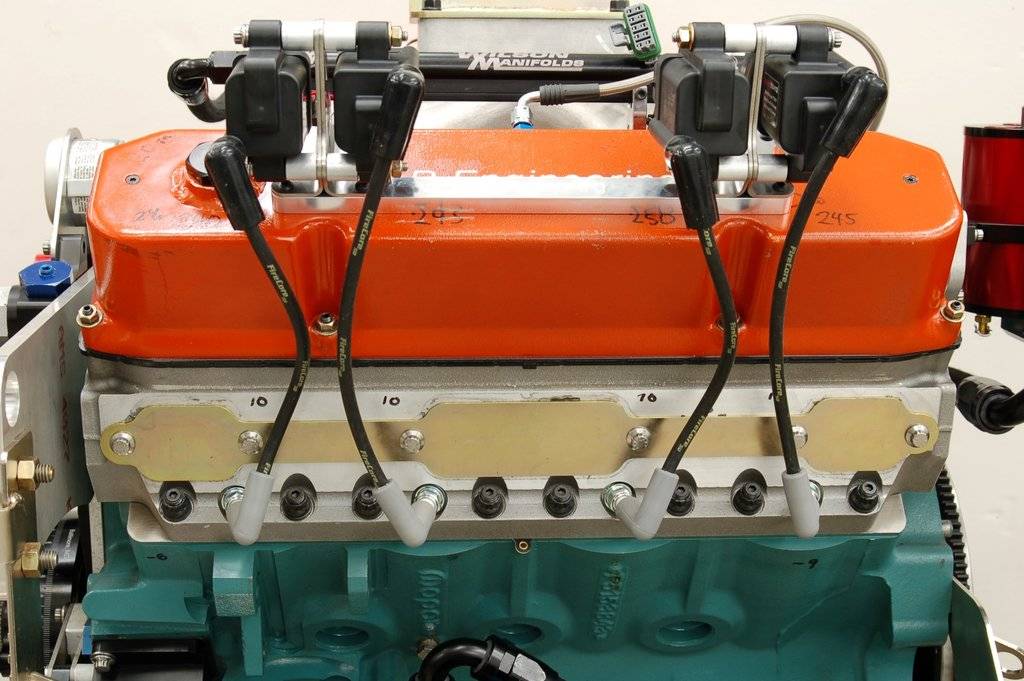

The coil brackets will work fine on a SB since a SB head is roughly the same size as a BB head. The coil pairs on this bracket are mounted about 9.5 inches apart. On a SB the perfect center to center distance would be 9.0 inches so that is not much difference. The coil pairs will only be 1/4 inch off center of the plugs which you probably won't even notice. You will need a set of valve covers with a flat top on them. I'm not sure if anyone makes a cast Magnum cover with a flat top so you might want to research that first.

I designed the brackets so the coils can be mounted at the valve cover angle (requires a 45 degree boot on the coil end of the spark plug wire) or the coils can be swung out and mounted so they are horizontal. When the coils are horizontal you can use a 90 degree boot on the coil end. The 90 degree boot is less expensive and easier to work with but the coils take up a little more room when mounted horizontal. Here are a couple of pictures showing the coils in the horizontal position. The bracket comes with both mounting positions so if a person gets this kit they can try both to see which they like the best. I think I'm going to run with the coils horizontal since I think it looks better but either will work.

mopar65

Well-Known Member

Looks killer Andy. I found a few places on eBay that sell them for a small block magnum. But I am not sure how good they are made. I was going to have a bunch of mounting stands welded to the valve covers for the coils. But your set up would be easer to set up I think. Here is a few picks I found if how I wanted to do mine

mopar65

Well-Known Member

Yep. I will smack my own hands 50 timesWell you did post pictures of a SB engine in the BB forum so I'm sure there is some sort of penalty to pay for that..........

BigBlockMopar

BigBlockMember

Do they play nice with the power brake booster in A-bodies?

inkjunkie

Well-Known Member

@AndyF....Found all the crank trigger/cam sync parts on your site. Bunch of questions. Didn't write anything down so if I ask something you covered on your site I apologize.

Motor plate necessary? Which water pump housing? Is your kit complete or will I need any other parts? Will only work with the one dampner? Any problems with mounting a pulley to spin an alternator/water pump?

Motor plate necessary? Which water pump housing? Is your kit complete or will I need any other parts? Will only work with the one dampner? Any problems with mounting a pulley to spin an alternator/water pump?

@AndyF....Found all the crank trigger/cam sync parts on your site. Bunch of questions. Didn't write anything down so if I ask something you covered on your site I apologize.

Motor plate necessary? Which water pump housing? Is your kit complete or will I need any other parts? Will only work with the one dampner? Any problems with mounting a pulley to spin an alternator/water pump?

If you are asking about the crank trigger wheels then you need to run an electric water pump or a remote pump to clear the larger diameter wheel. The trigger wheel is designed to fit on an ATI damper but it should fit on any damper that has a flat face. There is no problem adding a pulley to the front of the trigger wheel for an alternator or vacuum pump but the spacing won't be stock so you have to sort it out.

Holley HP kit 550-501 is what I used with 66 lb/hour injectors. Makes 900 hp @ 7000 rpm on race gas. I originally tried to use the Holley dual sync distributor but it didn't fit with my Indy heads so I made my own cam sync unit. Here is a picture:

View attachment 1715060538

Andy,

What are you running for your cam sync? I have read about the 68 charger that ran the Jeep 4.0 L cam sync with an adapter (Mopar Action had an article but didn't give him credit). But this looks like something different? Trying to do research for a low deck.

I started to make cam sync units since nobody else had one. I have them both for low deck and RB engines. You can buy them from Fast Man EFI. My cam sync housing is designed for the Ford Explorer sensor but you can also use the Jeep sensor if you want. They work the same, just have a different connector.

-