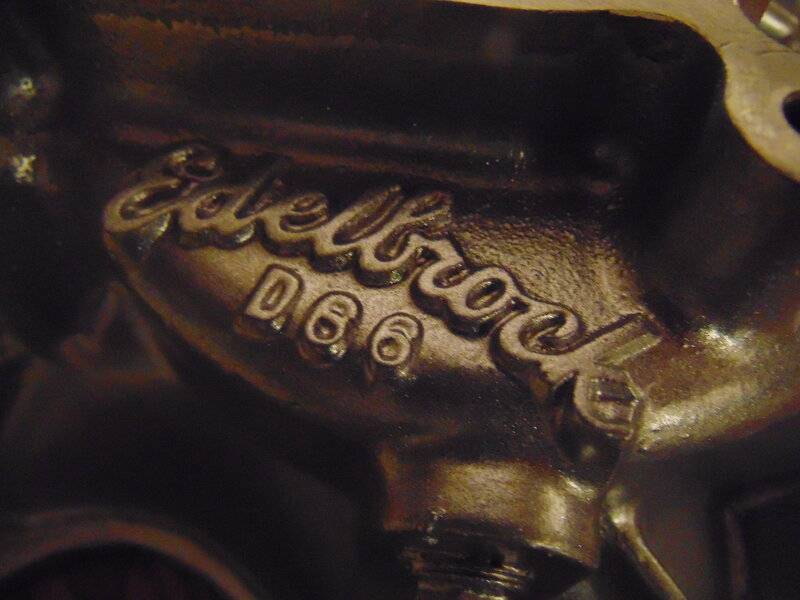

I've been looking for an Edelbrock D-66, dual plane dual quad manifold for small port (273-318) heads for a long time. I finally found one and it arrived yesterday. Here is what puzzles me: It's clearly a D-66, It has the larger bolt holes and they are straight (not ovaled out). The manifold is in great shape and was recently powdercoated. But the landing for the intake bolts is obviously canted (not perpendicular to the intake mating surface) like for a 64-5 273. The reason I sought this manifold out for my 318 build was that it was supposed to be a direct bolt on for 66 and up LA motors. What's going on????

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

D-66 questions

- Thread starter str12-340

- Start date

-

THat looks like a D64 for the 64 and 65 heads.

Yea it does though clearly marked D-66.

Thread sealer generously coating the bolt threads with a washer under them will do the trick.

Thread sealer generously coating the bolt threads with a washer under them will do the trick.

5/16" or 3/8" bolt holes?

I was not aware the bolt holes for the later model LA engines was perpendicular to the intake face. I do not think they are. I believe that intake is correct for its intended application. The earlier ones do have a different angle, but neither is perpendicular to the intake face as far as I remember.

Here's a LD4B. I think the bolt holes are perpendicular to the intake surface.

Here's a LD4B. I think the bolt holes are perpendicular to the intake surface.

View attachment 1715597453

View attachment 1715597456

They may be. I just remember something funny about them.....even the later ones. Maybe I'm rememberin the wrong memory. lol

They are holes for 3/8 bolts and they don't show up "ovaled" like when someone opens up the early LA holes for 3/8 bolts.

So I did some further investigation (inspired by Rusty's post). I headed to the parts shed and pulled out a D-64, a Wieand Stealth. an LD340, a Holley Streetmaster, and of course, I've got the D-66. I miced the bolt holes and the thickness of the manifold at the Valve cover and engine center sides of the bolt holes for 3 holes. The result is that, like Rusty remembered none of these manifolds are made with the bolt holes perpendicuar to the mating surface, but the "normal" LA manifolds have bolts that are half the amount out of perpendicular, as the 64-5 manifold. Here's the numbers (all measured in hundredths of an inch) :

D-66 bolt hole - .42

All other bolt holes - .46

Manifold/ Short side of bolt hole/ Tall side of bolt hole/ Difference

D-64 .56 .69 .13

.52 .66 .14

.89 1.05 .16

D-66 .46 .53 .07

.46 .52 .06

.46 .53 .07

Stealth .50 .56 .06

.50 .57 .07

.59 .65 .06

LD340 .52 .59 .07

.47 .53 .06

.72 .80 .08

Holley .51 .59 .08

.54 .60 .06

.44 .53 .07

Now all I need is an actual engineer! Since you have to reach just beyond the bolt hole to measure the fat side, let's say the distance for a regular LA is actually .48 inches. The average difference in thickness is .07 inches. On the 64-5 manifold the distance is .44 inches and the difference is .14. Given all that, an engineer could tell you the angle of taper on a washer needed to correct the bolt head mating angle to use a 64-5 manifold on a 66 and up engine. I think you could then flip the washer and use any 66 and up LA manifold on an early LA. (you might have to correct the bolt hole angle in some cases, but not by much.)

OK so you guys know better than I who the whiz is that can give us the angle of taper for the washer and bring them in to this thread. I've found a few different sources for round tapered washers and they all seem to sell them by taper angle.

D-66 bolt hole - .42

All other bolt holes - .46

Manifold/ Short side of bolt hole/ Tall side of bolt hole/ Difference

D-64 .56 .69 .13

.52 .66 .14

.89 1.05 .16

D-66 .46 .53 .07

.46 .52 .06

.46 .53 .07

Stealth .50 .56 .06

.50 .57 .07

.59 .65 .06

LD340 .52 .59 .07

.47 .53 .06

.72 .80 .08

Holley .51 .59 .08

.54 .60 .06

.44 .53 .07

Now all I need is an actual engineer! Since you have to reach just beyond the bolt hole to measure the fat side, let's say the distance for a regular LA is actually .48 inches. The average difference in thickness is .07 inches. On the 64-5 manifold the distance is .44 inches and the difference is .14. Given all that, an engineer could tell you the angle of taper on a washer needed to correct the bolt head mating angle to use a 64-5 manifold on a 66 and up engine. I think you could then flip the washer and use any 66 and up LA manifold on an early LA. (you might have to correct the bolt hole angle in some cases, but not by much.)

OK so you guys know better than I who the whiz is that can give us the angle of taper for the washer and bring them in to this thread. I've found a few different sources for round tapered washers and they all seem to sell them by taper angle.

Last edited:

Do you have a drive shaft angle finder?

nope... if I could borrow one would it fit down in between the intake runners?

Enough to do the job, yea I think so.

So I did some further investigation (inspired by Rusty's post). I headed to the parts shed and pulled out a D-64, a Wieand Stealth. an LD340, a Holley Streetmaster, and of course, I've got the D-66. I miced the bolt holes and the thickness of the manifold at the Valve cover and engine center sides of the bolt holes for 3 holes. The result is that, like Rusty remembered none of these manifolds are made with the bolt holes perpendicuar to the mating surface, but the "normal" LA manifolds have bolts that are half the amount out of perpendicular, as the 64-5 manifold. Here's the numbers (all measured in hundredths of an inch) :

D-66 bolt hole - .42

All other bolt holes - .46

Manifold/ Short side of bolt hole/ Tall side of bolt hole/ Difference

D-64 .56 .69 .13

.52 .66 .14

.89 1.05 .16

D-66 .46 .53 .07

.46 .52 .06

.46 .53 .07

Stealth .50 .56 .06

.50 .57 .07

.59 .65 .06

LD340 .52 .59 .07

.47 .53 .06

.72 .80 .08

Holley .51 .59 .08

.54 .60 .06

.44 .53 .07

Now all I need is an actual engineer! Since you have to reach just beyond the bolt hole to measure the fat side, let's say the distance for a regular LA is actually .48 inches. The average difference in thickness is .07 inches. On the 64-5 manifold the distance is .44 inches and the difference is .14. Given all that, an engineer could tell you the angle of taper on a washer needed to correct the bolt head mating angle to use a 64-5 manifold on a 66 and up engine. I think you could then flip the washer and use any 66 and up LA manifold on an early LA. (you might have to correct the bolt hole angle in some cases, but not by much.)

OK so you guys know better than I who the whiz is that can give us the angle of taper for the washer and bring them in to this thread. I've found a few different sources for round tapered washers and they all seem to sell them by taper angle.

SO I was right. I thought I remembered that right.

gregcon

Well-Known Member

- Joined

- Dec 20, 2009

- Messages

- 735

- Reaction score

- 820

You don't need an engineer, just draw a triangle using the 3 dimensions you want the angle washer to look like. Then, use those dimensions to calculate the angle using the cosine divided by the tangent of the arc multiplied by the quadrilateral corollary of the late afternoon sun.

Actually, go to a search engine and type in 'triangle calculator' and it'll tell you the angle.

The hard part, of course, will be finding someone to produce said washers for you....cutting a washer on a slight angle, accurately, is tougher than it sounds.

If it was me...I'd forsake that fancy aluminum paint job in the interest of machining the proper angle into the intake boss so a normal bolt and washer would be used.

Actually, go to a search engine and type in 'triangle calculator' and it'll tell you the angle.

The hard part, of course, will be finding someone to produce said washers for you....cutting a washer on a slight angle, accurately, is tougher than it sounds.

If it was me...I'd forsake that fancy aluminum paint job in the interest of machining the proper angle into the intake boss so a normal bolt and washer would be used.

Probably the easiest way to measure the angle of the intake bolts is to screw a long bolt into a cylinder head and measure the angle with a protractor.

There was a thread about this a week ago on one of these sites. McMaster-Carr has angled washers available.

Someone even measured the angle here.

Intake differance 273, 340, 360

Someone even measured the angle here.

Intake differance 273, 340, 360

And the head bolt holes are also canted, It is correct.the landing for the intake bolts is obviously canted (not perpendicular to the intake mating surface)(/QUOTE]

And the head bolt holes are also canted, It is correct.

That's crazy.And the head bolt holes are also canted, It is correct.

View attachment 1715597659

You don't need an engineer, just draw a triangle using the 3 dimensions you want the angle washer to look like. Then, use those dimensions to calculate the angle using the cosine divided by the tangent of the arc multiplied by the quadrilateral corollary of the late afternoon sun.

Like I said, where are the engineers?????

The hard part, of course, will be finding someone to produce said washers for you....cutting a washer on a slight angle, accurately, is tougher than it sounds.

Actually there are a few producers of both the square and round taper cut washers in various angles, so if I can calculate the angle, I'm hoping I an luch into something within a degree of perfect.

The aluminum paint job is the powdercoat the former owner had done (I was sceptical but its growing on me in terms of both looks and durability)- that D-66 I can actually use as is now that I know that the angle is correct for all 66 and up LA motors. Now I'm trying to figure out how to make my D-64 more useful by using the right washers - IMHO getting the angle right through machining (or even worse - grinding) seems to be a fools errand given each of these surfaces are down in odd shaped recesses in the manifold...

You may want to look into something like this.

https://www.amazon.com/gp/product/B00GDWH25U/?tag=fabo03-20

I'll go out to the shed and pull a block, heads, and a manifold and stick them together and snap some pictures today.

No head gaskets here, just sticking it all together like legos.

These are 302 heads and 340/360 gaskets, Felpro 1213's, just using them to get the spacing right.

I was only able to find one of the intake manifold bolts, you can see the spherical washers doing their job here so the pressure is distributed more evenly on the bolt head and the manifold.

The above picture is the D-64 manifold. The following pic is of an Offenhauser 5488 at the same bolt hole. Both of these intakes are drilled for the 64/65 angle, but with a little work will mate right up with the regular LA manifold bolt angle.

Gratuitous car **** shot.

https://www.amazon.com/gp/product/B00GDWH25U/?tag=fabo03-20

I'll go out to the shed and pull a block, heads, and a manifold and stick them together and snap some pictures today.

No head gaskets here, just sticking it all together like legos.

These are 302 heads and 340/360 gaskets, Felpro 1213's, just using them to get the spacing right.

I was only able to find one of the intake manifold bolts, you can see the spherical washers doing their job here so the pressure is distributed more evenly on the bolt head and the manifold.

The above picture is the D-64 manifold. The following pic is of an Offenhauser 5488 at the same bolt hole. Both of these intakes are drilled for the 64/65 angle, but with a little work will mate right up with the regular LA manifold bolt angle.

Gratuitous car **** shot.

Last edited:

67Dart273

Well-Known Member

You don't need an engineer, just draw a triangle using the 3 dimensions you want the angle washer to look like. Then, use those dimensions to calculate the angle using the cosine divided by the tangent of the arc multiplied by the quadrilateral corollary of the late afternoon sun.

Actually, go to a search engine and type in 'triangle calculator' and it'll tell you the angle.

The hard part, of course, will be finding someone to produce said washers for you....cutting a washer on a slight angle, accurately, is tougher than it sounds.

If it was me...I'd forsake that fancy aluminum paint job in the interest of machining the proper angle into the intake boss so a normal bolt and washer would be used.

Actually THIS IS the definition of engineering LOL

But damn I had no idea late LA were not perpendicular!! They can't be off much??

kowalski440

Well-Known Member

I recall there being an app for your phone that can do that, also.Do you have a drive shaft angle finder?

Actually THIS IS the definition of engineering LOL

But damn I had no idea late LA were not perpendicular!! They can't be off much??

It's a pretty good bit. Look at post #17. LOL

-