pishta

I know I'm right....

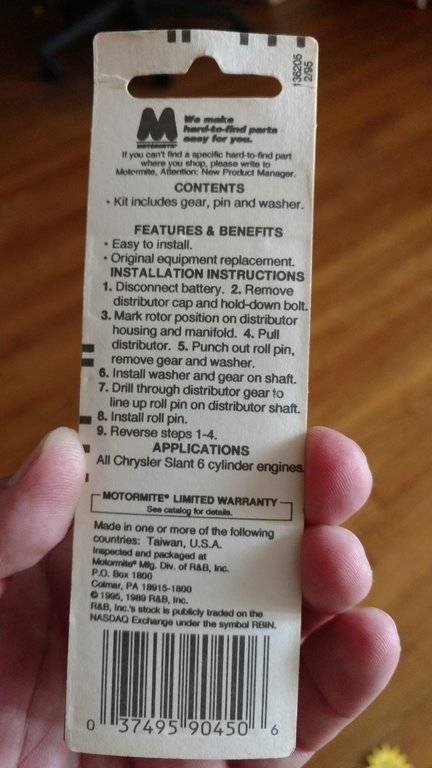

I got this blast from the past in the mail today

But the gear pin hole is too high, does it matter or is there a proper clearance for the end play of the shaft? There is like 3mm of difference in the spring-pin holes. Do I cross drill the gear to match the old hole level and retain the old endplay or does it matter? Im using it as a CPS for sequential EFI using only 1 reluctor vane, and I can put it anywhere in the cam rotation.

But the gear pin hole is too high, does it matter or is there a proper clearance for the end play of the shaft? There is like 3mm of difference in the spring-pin holes. Do I cross drill the gear to match the old hole level and retain the old endplay or does it matter? Im using it as a CPS for sequential EFI using only 1 reluctor vane, and I can put it anywhere in the cam rotation.