"Flare". Except for metric "stuff" here's what you have

AN or also called JIC in the tractor / hydraulic / industrial crowd. This uses male adapters, with female flare nuts, but the FLARE ANGLE is 37 degrees, so requires a different tool.

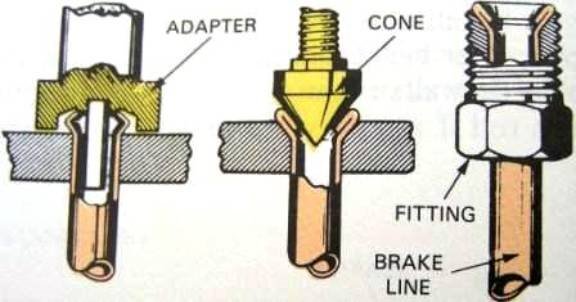

JIC flare:

SAE flare. This also uses male adapter fittings and female nuts. This is most commonly found as the brass stuff you find in parts stores and hardware stores.

Inverted flare. This is what brake systems commonly use. It's called inverted because the adapters are female and the nuts on the lines are male.

The Last two systems, SAE and inverted flare BOTH use the same line flare tool. This is a 45 degree flare angle

DOUBLE flare has nothing to do with the types of fittings or inverted or SAE. Double flare means you make a "double fold" with the tool. This folds the raw edge of the line in like a cuff on your pants to prevent it from splitting.

One type of double flare tool procedure:

Below, the left line is a SINGLE flare. You just stick it in the tool, use the cone as in the diagram above, without the "double flare" adapter first, and you get a simple bell shaped flare. Raw outer edge, prone to splitting

The middle line is the start of a formation of a double flare

The right line, below, is a finished double flare