Is there one that really works and doesn't cost like it's off the Snap On truck?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drill Bit Sharpener

- Thread starter RustyRatRod

- Start date

-

I sold a lot of Drill Doctors but they are temperamental and everyone can't get them to work right. 1/4" and bigger bits is what I always recommended.

Drill Doctor DD750X $139 Amazon too much?

I sometimes use a "Drill Doctor" but i haven't a clew anymore what i paid for it.

Seems to be the most popular one, that's out there on the marketplace.

Seems to be the most popular one, that's out there on the marketplace.

The drill doctor works good. Its hard to get small bits indexed but it will sharpen them. Anything smaller than 1/8" doesnt work well.

Also, it wont do split point or other multi angle bits.

Also, it wont do split point or other multi angle bits.

C130 Chief

Mechanical Genius

I have a Drill Doctor, and it works pretty well, but I generally just freehand grind, it's way faster. Besides taking a fair amount of time to set up, Drill Doctors only handle relatively smallish bits which are more economically just replaced.

Lisle makes, or made a really nice sharpener, and I'd let one follow me home for the right price. mrpete222 did a series on refurbishing one of these a while back

Lisle makes, or made a really nice sharpener, and I'd let one follow me home for the right price. mrpete222 did a series on refurbishing one of these a while back

I've tried all my life and never had any luck free handing drill bits. Our auto shop instructor in high school could do it almost without even lookin at the grinder. lol I may have gotten three sharpened all my life. lol

grimreaper

Cross Member

Get an old large bit, 1/2" or larger and a new one you can look at for comparison. Make sure your stone is dressed to a flat face. Try to maintain the same angle that the bit had to begin with and keep the heel just very slightly deeper than the cutting edge. Do your sharpening above the centerline on the grinding wheel. (Which is usually above the tool rest as thy are approximately on center.) Make multiple light passes rather than a heavy grind and make the same number of passes on both cutting edges. Then keep trying until you get a grind that cuts well. It's difficult to get the correct angle on small bits until you are used to doing it on larger ones.

I've got a Drill Doctor but don't like it. I can do a better job faster with just my bench grinder. If the bit isn't indexed exactly in the Drill Doctor the bit won't cut.

I've got a Drill Doctor but don't like it. I can do a better job faster with just my bench grinder. If the bit isn't indexed exactly in the Drill Doctor the bit won't cut.

Retired tool and die maker here. Free hand sharpening is mostly understanding the angles and clearances involved in tipping a drill. But after that its all about doing it alot. If someone is paying you $40 an hour, you get paid to pound holes and not sharpen drills so you get after it right quick so motivation is a real big factor.

But honestly I’ve revisited the grinder with a drill I just sharpened cause it would not cut the way I wanted it to before I even got one hole done Many times.

but if you don’t understand the angles no drill sharpener is going to do you much good.

But honestly I’ve revisited the grinder with a drill I just sharpened cause it would not cut the way I wanted it to before I even got one hole done Many times.

but if you don’t understand the angles no drill sharpener is going to do you much good.

dodgedifferent2

Well-Known Member

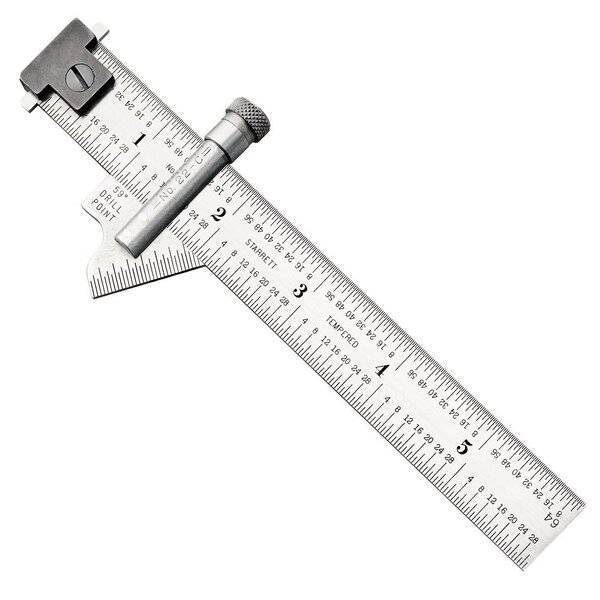

General machinist here. Drill point gauge is your friend.

Take that drill dr and throw it in the trash. The one my father bought a few years back, he could not replace the wheel. So the bits never sharpened correctly.

I bought a table grinder and a drill point gauge and dropped it off to him. Now he has sharp drill bits.

Yes, there are days my touch is off and i have to visit the grinder again.

Take that drill dr and throw it in the trash. The one my father bought a few years back, he could not replace the wheel. So the bits never sharpened correctly.

I bought a table grinder and a drill point gauge and dropped it off to him. Now he has sharp drill bits.

Yes, there are days my touch is off and i have to visit the grinder again.

Last time harbor freight drill sets went on sale for $10, I bought three sets. Now I use them till too many are dull or broke & throw the box in the trash & pull out a new box.

Rob I have been using one made by Foley belsaw for years. Mount it next to your bench grinder or belt sander it does them all. Cheap also around 30 on e bay.

Dam HD has the same thing 21!

General Tools Drill Bit Sharpener & Grinding Tool Attachment 825 (homedepot.com)

General Tools Drill Bit Sharpener & Grinding Tool Attachment 825 (homedepot.com)

Jeremiah (jd)

Well-Known Member

Go for the attachment as ahown above. Drill Dr. Is too flimsey imo.

Last edited:

They are great. up to 3/4" I believe that one is.

Yote

Well-Known Member

I have used the one Mattax suggested, a Sears electric sharpener (I gave to my son) and currently have a Drill Doctor 750. They will all work fine, but as mentioned above understanding the angles is important. When you get one don’t get in a hurry as there is a learning curve involved.

My Drill Doctor ‘will’ do a split point up to 3/4”and care needs to be taken to not destroy the sharpening wheels.

Also as mentioned, the under 1/8” bits are better to just replace. Too difficult to index correctly.

Yote

My Drill Doctor ‘will’ do a split point up to 3/4”and care needs to be taken to not destroy the sharpening wheels.

Also as mentioned, the under 1/8” bits are better to just replace. Too difficult to index correctly.

Yote

Last edited:

bcschief

Well-Known Member

I have an old school Drill Doctor 750 it does a great job on bits 3/16 and larger the smaller bits I just buy new ones.

I have a Drill Doctor, and it works pretty well, but I generally just freehand grind, it's way faster. Besides taking a fair amount of time to set up, Drill Doctors only handle relatively smallish bits which are more economically just replaced.

Lisle makes, or made a really nice sharpener, and I'd let one follow me home for the right price. mrpete222 did a series on refurbishing one of these a while back

I have a lisle one, I need to get it off the shelf and set up, I have a drill doctor that I used for a while til the novelty wore off, have tried to sell it at a few garage sales and nobody even asks about it. I even have the VHS tape that came with it to tell about it, that has never been played

I have something big leaving my attached garage, (what is leaving, isn't automotive in nature) I am getting 2 things in its place that won't quite take up all the space it has occupied for the last several years, so maybe I'll have room to actually set it up.

Both things I'm getting will be easier to move around than what's leaving.

Gonna have to find some goodies to make me a stand to mount the Lisle drill bit machine onto at that point.

unless I can find a bench grinder stand with a dead grinder attached, somehow.

Mopar44134

Well-Known Member

never in my life have i wore out a drill bit smaller than an 1/8th. I usually break them before they wear out. lol

They get dull, you push too hard, pop!never in my life have i wore out a drill bit smaller than an 1/8th. I usually break them before they wear out. lol

-