probably this post will get moved but oh well. is it feasible to bolt a dual pattern carb magnum intake to the magnum heads and THEN drill the la holes for an la intake? please point out what might be wrong in my thought process other than just saying no, won't work. thought on this is that la intakes are cheaper than the mag carb ones and more choices.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

drilling magnum heads

- Thread starter rbkt65

- Start date

-

pishta

I know I'm right....

Sure, as using it as a guide? No problem. Have a sharp bit and make sure you got the meat for it. The "Magnum jig" was just a series of drill guides on a bolt on fixture.

Professor Fate

Push the button, Max...

As far as using the manifold as a guide, I have no idea how you'd ever be able to do the LA center four holes...

Bobzilla

Well-Known Member

You would not use the intake as a drill guide. You can use it to locate and mark the LA holes, then you would drill the holes using a drill press or very careful hand drilling.

The holes in the dual pattern intake are too large to use as a drill guide.

I am considering doing this myself but I just laid the LA gasket over the intake and coolant ports, center marked each LA bolt hole with a fine tip marker, and then laid the intake in place with gaskets and verified the holes line up with my marks. I have not actually drilled it yet.

Edited to add:

The jig shown in post 2 is the best idea for doing multiple sets of heads. But for just one set, mark it and drill it carefully.

The holes in the dual pattern intake are too large to use as a drill guide.

I am considering doing this myself but I just laid the LA gasket over the intake and coolant ports, center marked each LA bolt hole with a fine tip marker, and then laid the intake in place with gaskets and verified the holes line up with my marks. I have not actually drilled it yet.

Edited to add:

The jig shown in post 2 is the best idea for doing multiple sets of heads. But for just one set, mark it and drill it carefully.

Bobzilla

Well-Known Member

A short pen, pencil, or even a nail or scribe will still mark these holes accurately enough for drilling. You cannot use the intake itself as a drill guide anyways.As far as using the manifold as a guide, I have no idea how you'd ever be able to do the LA center four holes...

View attachment 1715728950

Professor Fate

Push the button, Max...

Yeah, that's kinda what I was getting at...A short pen, pencil, or even a nail or scribe will still mark these holes accurately enough for drilling. You cannot use the intake itself as a drill guide anyways.

JDMopar

Well-Known Member

@Stephen Hotz made a jig, and is kind enough to let it float around for other members to drill LA pattern into their Magnum heads!

macdrew77

Well-Known Member

Do you have a spare LA head and a welder? Jig is fairly simple to make. I drilled my mag head for 5/16-18 and both bolt patterns are useable actually.

Not sure currently where the plates are but should still be out there.

67Dart273

Well-Known Member

YOU sir are a TRUSTING soul!!!Not sure currently where the plates are but should still be out there.

YOU sir are a TRUSTING soul!!!

Yup. He and his family are FINE people. They give hope for the future.

Ive got them, and they are wrapped in original packaging+, and ready to go..Not sure currently where the plates are but should still be out there.

Just need a name and address...

naji408

Well-Known Member

Ive got them, and they are wrapped in original packaging+, and ready to go..

Just need a name and address...

Is there a list to get on? I would love to get them.

I would also like to use it, I would gladly pay to rent it. Thanks ...Shane

Barracuda2015

Member

I would also like to get on the list for the jig. Be glad to pay shipping. Thanks.

In the meantime, Naji408 requested the Jig. Was stuck at work till after the P.O? Closed and didnt get them mail out fast enough. He found a machine shop local to his location and had them complete the machine work. So had them for a bit longer.. next person requested the use of them, so I delivered them personally, and got to meet another ForAbody member!

The Jig was delivered to 540 Valiant just recently. Maybe a quick note from next in line, (with address) so when he's done, he can send the package out.

Maybe if someone has a little extra time after using, they could make anotther setup, with a few upgrades/tweaks that they thought of. That way, there could be a couple sets out there that could be borrowed/making the rounds!

(Kinda the same like loan a tool at AutoZone)

The Jig was delivered to 540 Valiant just recently. Maybe a quick note from next in line, (with address) so when he's done, he can send the package out.

Maybe if someone has a little extra time after using, they could make anotther setup, with a few upgrades/tweaks that they thought of. That way, there could be a couple sets out there that could be borrowed/making the rounds!

(Kinda the same like loan a tool at AutoZone)

Last edited:

Keystone

Well-Known Member

Bumping this thread as it's apparently the current one for tracking the whereabouts of the drilling fixture. I contacted 540Valiant and he's about ready to send it to someone after him (I'm guessing Barracuda2015) and I'm requesting it after that. I'll post back when it's ready to send on to the next member.

On a lil different note, it was nice to look at the packaging and see where the package had been before. That setup is getting a lot of miles on it!

Cornernfool

Well-Known Member

So who do I talk to about renting or using the drill fixture? Thanks!

Keystone

Well-Known Member

I have it currently. Should be able to get to it in a couple weeks, then I'll send it to you. PM me your shipping address and I'll let you know when it's on its way.So who do I talk to about renting or using the drill fixture? Thanks!

Btw, there was a local pickup prior to me receiving it, and it came to me without me paying shipping, so I'm going to pay the shipping to the next member. Hopefully we can keep it going like that.

Cornernfool

Well-Known Member

Does the head need to be off the block to drill or will the fixture work with the head bolted to the block? Here's what I have to bolt on to my Magnum.

Keystone

Well-Known Member

I wanted to post some additional information about this, because maybe that can be of use to someone. So first of all, there are two fixtures. One is for drilling the center 4 holes, and the other is for the holes on either end of the head. There are 4, 1/8" NPT pipe nipples that thread into tapped holes in the fixtures to act as drill bushings to guide your bit. Here's the fixture on the head:

On the fixture for the center holes, the 2 end holes are drilled at the angle of the Magnum bolts to locate and secure the fixture to the head. The problem I had though is that there was a slight misalignment and I couldn't get them to thread in. If I pulled it away they'd start but there wasn't enough clearance to slide it back flush with the head:

It was very close and probably just need a slight bit of material removed with a round file, but these pieces aren't mine and I didn't want to modify anything. I reached out to Stephen and he said clamping it to the head instead of bolting it should work just fine, so that's what I did:

I'm not sure if it was just my heads, but in the end it worked just out. One more tip, when tapping the holes, you can re-insert the drill bit to visually help you keep the tap aligned while getting started:

And the 4 in the center portion of the head are thru-holes, so you don't have to worry about going too deep (don't know why it's rotating this picture, sorry):

In the end, this is what you want. The view from the camera is the newly drilled and tapped hole, and at the bottom is the factory 5/16" hole:

Hope that makes things a little clearer for anyone going forward. And thanks again to Stephen for not only making this tools, but allowing everyone here to use it.

Oh, and to Cornernfool, I'm almost positive you'll have to have the heads off the block to make this work.

On the fixture for the center holes, the 2 end holes are drilled at the angle of the Magnum bolts to locate and secure the fixture to the head. The problem I had though is that there was a slight misalignment and I couldn't get them to thread in. If I pulled it away they'd start but there wasn't enough clearance to slide it back flush with the head:

It was very close and probably just need a slight bit of material removed with a round file, but these pieces aren't mine and I didn't want to modify anything. I reached out to Stephen and he said clamping it to the head instead of bolting it should work just fine, so that's what I did:

I'm not sure if it was just my heads, but in the end it worked just out. One more tip, when tapping the holes, you can re-insert the drill bit to visually help you keep the tap aligned while getting started:

And the 4 in the center portion of the head are thru-holes, so you don't have to worry about going too deep (don't know why it's rotating this picture, sorry):

In the end, this is what you want. The view from the camera is the newly drilled and tapped hole, and at the bottom is the factory 5/16" hole:

Hope that makes things a little clearer for anyone going forward. And thanks again to Stephen for not only making this tools, but allowing everyone here to use it.

Oh, and to Cornernfool, I'm almost positive you'll have to have the heads off the block to make this work.

Keystone

Well-Known Member

One other thought here... I think there is a way to do this like some earlier posted suggested, by using an intake manifold as a guide. But you would need a few specific things.

1) a 2-barrel intake manifold. The section under the carb is much smaller and allows access to all the holes. I laid this on my block/heads while waiting for the drilling rig to arrive, using some paper board to approximate the thickness of the gaskets, just wondering about possibilities. This should work:

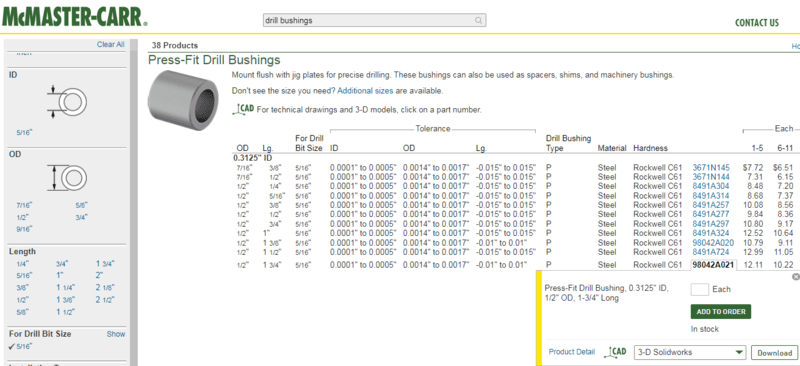

2) A drill bushing for a 5/16" bit, 5/16 being the tap drill for the 3/8" sized LA manifold bolts. $12 from McMaster:

The only catch with that is, while you can get the right ID, they don't come in the required OD. I recall the holes in the 2-barrel manifold were 29/64", but don't quote me on that. You'd have to get someone to turn a portion of one of the ends down to fit the holes in the manifold. Shouldn't be hard for a machinist.

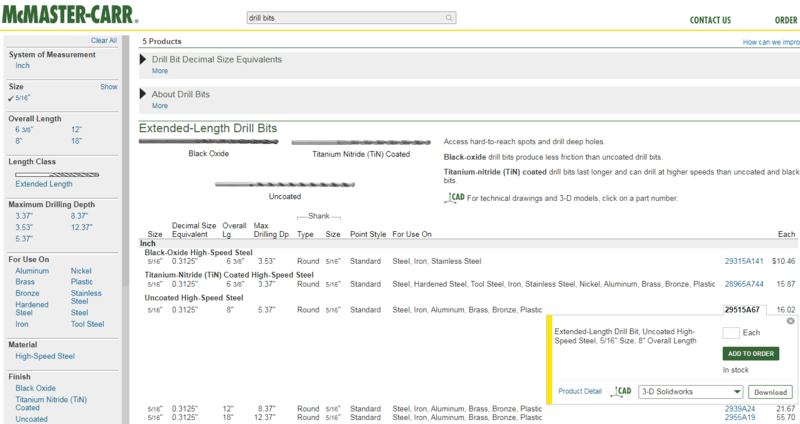

3) A longer than standard drill bit. Based on some rough measurements I took from the required depth of the holes, the thickness of the manifold, and the height of the runners, you'd need about 6", plus a little more for the chuck to hold. So something like this, again from McMaster is $16:

Again, just thinking out loud here, but this may be a viable option for someone who can't wait for the fixture, or who doesn't want to remove the heads.

1) a 2-barrel intake manifold. The section under the carb is much smaller and allows access to all the holes. I laid this on my block/heads while waiting for the drilling rig to arrive, using some paper board to approximate the thickness of the gaskets, just wondering about possibilities. This should work:

2) A drill bushing for a 5/16" bit, 5/16 being the tap drill for the 3/8" sized LA manifold bolts. $12 from McMaster:

The only catch with that is, while you can get the right ID, they don't come in the required OD. I recall the holes in the 2-barrel manifold were 29/64", but don't quote me on that. You'd have to get someone to turn a portion of one of the ends down to fit the holes in the manifold. Shouldn't be hard for a machinist.

3) A longer than standard drill bit. Based on some rough measurements I took from the required depth of the holes, the thickness of the manifold, and the height of the runners, you'd need about 6", plus a little more for the chuck to hold. So something like this, again from McMaster is $16:

Again, just thinking out loud here, but this may be a viable option for someone who can't wait for the fixture, or who doesn't want to remove the heads.

Keystone

Well-Known Member

And one last thing... You can't use the manifold as a template to spot the holes with a transfer punch because you're not drilling into virgin metal. You have to go through the same location as the Magnum bolt holes, just at a different angle. Like this:

-