I am new to the website. Working on a 67 valiant. I have magnum forces 2 inch drop spindles. Wondering if anybody has put these on and what backpacking they have used. Was thinking of doing 15x6 steel wheels. Sounds like 4.5 to 5 has been the standard for backspacing with the drop spindles.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

drop spindles

- Thread starter chodge

- Start date

-

dodgedartgt

Well-Known Member

- Joined

- Dec 2, 2006

- Messages

- 215

- Reaction score

- 19

I'll push this back to the top, because I'm interested as well.

Thnx, Mike in FL

Thnx, Mike in FL

vntned

Well-Known Member

I'm running 2" drop spindles with a disk brake conversion on the front of my '64. The wheels up front are currently 17x7s with 4.2" of back spacing, however I previously had 15x7 cop car wheels which have 4.5" of back spacing, I believe. They cleared fine!

Drop spindles are 100% unnecessary on a torsion bar suspension. By far one of the greatest advantages of the torsion bar design is the ability to raise and lower the ride height.

I used to run the 2" drop spindles on my Challenger. It was the one of the first things I did to the car, and before I had a good handle on how the torsion bar suspension works. I removed them, put the stock spindles back in, and lowered my car to the EXACT same ride height using just the torsion bar adjusters. There are two things you do have to take into account when you lower using the torsion bars though. First, you lose suspension travel. That's a problem only if you don't increase the size of your torsion bars. If you do increase the size of your torsion bars, you don't need, and won't use, all of that travel. Second, as you lower the car with the torsion bars the negative camber on the car will increase, which is good, but you lose caster. The best way to get that back is with a set of Moog offset UCA bushings, #7103, or a set of tubular UCA's with additional caster already built in.

My Challenger sits with the wheel arches 25" off the pavement. I swapped out the stock LCA bumpstops for more clearance. The stock bump stops were designed to be "used" as part of the suspension, that's why they're tall and progressive, they actually add spring rate as the bumpstops hit the frame and compress. That's fine if you want to run a really soft spring rate like the factory did, but if you increase the size of your torsion bar to have the spring rate that you want, you don't want or need to use the bumpstops. So they can be swapped out for poly "button" style bumpstops, which allow for more clearance. I have about 15/16" from my bumpstops to my frame on my Challenger, and I almost never hit them with the 1.12" torsion bars I have.

My Duster has even less clearance. I've lowered it down to 24 7/8" from the wheel arch to the pavement. The bumpstops I use are 3/8" tall, (http://www.summitracing.com/parts/ens-9-9132g/overview/) and even using those I only have about 7/8" travel from the LCA to the bumpstop. I've never hit them. Again, that's with a 1.12" torsion bar, which is a 300 lb/in wheel rate. So probably stiffer than most folks want to go. But, even with a 1.03" bar, you need less than half the amount of travel as a stock torsion bar. Keep in mind the stock wheel rate was 90-110 lb/in on these cars. A 1.03" bar has a wheel rate in the 220 lb/in range, more than DOUBLE the stock wheel rate. Which means, less than half the suspension travel as the stock bars.

The drop spindles also increase bump steer, and raise your roll center for a given ride height compared to lowering with the torsion bars. Compared to lowering with the torsion bars, when you lower the car 2" with the drop spindles your UCA's and LCA's remain at the same angle, and your steering point is moved away from your wheel center. When you lower with the torsion bars, the angle of the UCA's and LCA's change. When the UCA's are parallel to the ground, your camber curve is entirely favorable. And upward deflection of the UCA adds negative camber to the wheel, which improves handling. The roll center is also quite low at that point.

So, instead of spending $500 on drop spindles, buy a set of torsion bars and offset bushings and do it right for less.

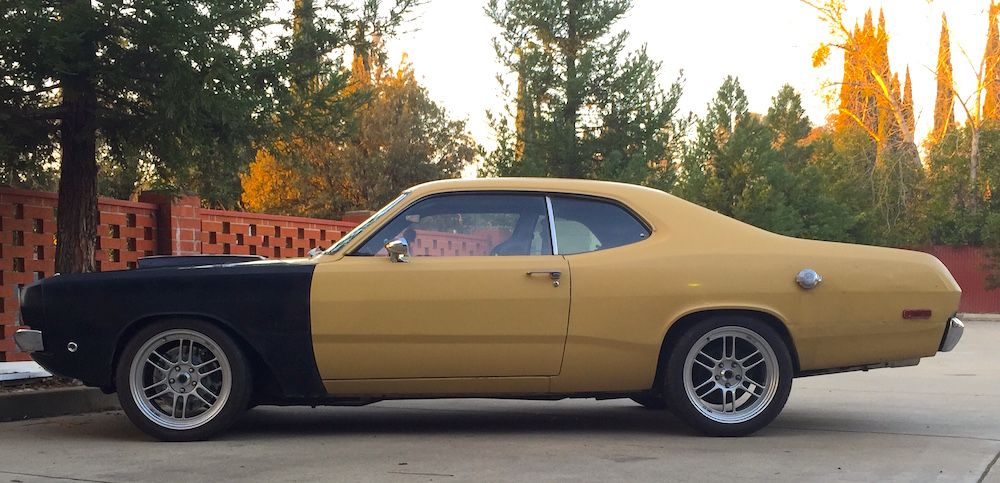

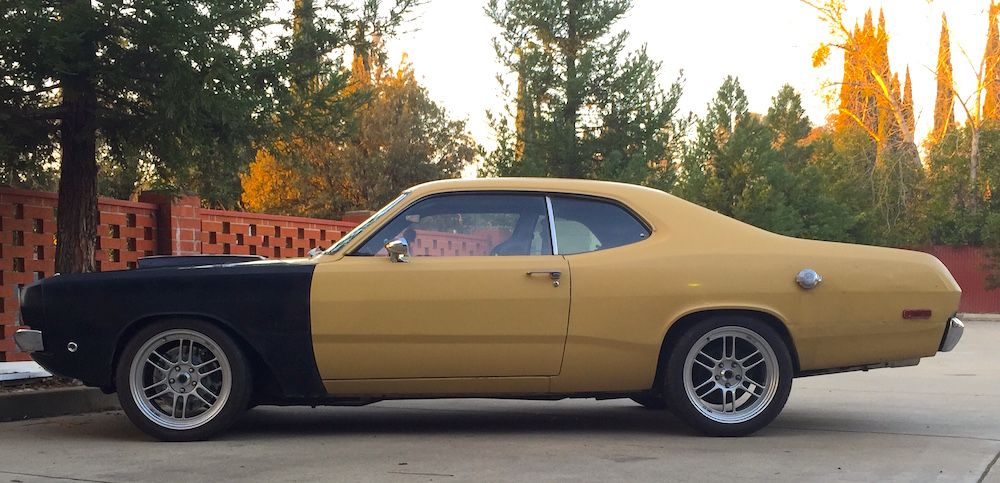

This is how my Duster was sitting when the wheel arch was at 25 1/8". I've lowered it another 1/4" since then, and may go a little lower before I'm done. Stock spindles, stock LCA's, and the 3/8" bumpstop I linked earlier. I do have tubular UCA's to clear my 18x9" rims in the front. My ride height will end up being dictated by the 275/35/18's I have up front, I won't be able to lower it as much as vntnd to tuck the wheels because the tires are too close the fenders. I'd also probably run out of clearance to the top of the inner fender, with 25.7" tall tires I don't have much vertical clearance.

I used to run the 2" drop spindles on my Challenger. It was the one of the first things I did to the car, and before I had a good handle on how the torsion bar suspension works. I removed them, put the stock spindles back in, and lowered my car to the EXACT same ride height using just the torsion bar adjusters. There are two things you do have to take into account when you lower using the torsion bars though. First, you lose suspension travel. That's a problem only if you don't increase the size of your torsion bars. If you do increase the size of your torsion bars, you don't need, and won't use, all of that travel. Second, as you lower the car with the torsion bars the negative camber on the car will increase, which is good, but you lose caster. The best way to get that back is with a set of Moog offset UCA bushings, #7103, or a set of tubular UCA's with additional caster already built in.

My Challenger sits with the wheel arches 25" off the pavement. I swapped out the stock LCA bumpstops for more clearance. The stock bump stops were designed to be "used" as part of the suspension, that's why they're tall and progressive, they actually add spring rate as the bumpstops hit the frame and compress. That's fine if you want to run a really soft spring rate like the factory did, but if you increase the size of your torsion bar to have the spring rate that you want, you don't want or need to use the bumpstops. So they can be swapped out for poly "button" style bumpstops, which allow for more clearance. I have about 15/16" from my bumpstops to my frame on my Challenger, and I almost never hit them with the 1.12" torsion bars I have.

My Duster has even less clearance. I've lowered it down to 24 7/8" from the wheel arch to the pavement. The bumpstops I use are 3/8" tall, (http://www.summitracing.com/parts/ens-9-9132g/overview/) and even using those I only have about 7/8" travel from the LCA to the bumpstop. I've never hit them. Again, that's with a 1.12" torsion bar, which is a 300 lb/in wheel rate. So probably stiffer than most folks want to go. But, even with a 1.03" bar, you need less than half the amount of travel as a stock torsion bar. Keep in mind the stock wheel rate was 90-110 lb/in on these cars. A 1.03" bar has a wheel rate in the 220 lb/in range, more than DOUBLE the stock wheel rate. Which means, less than half the suspension travel as the stock bars.

The drop spindles also increase bump steer, and raise your roll center for a given ride height compared to lowering with the torsion bars. Compared to lowering with the torsion bars, when you lower the car 2" with the drop spindles your UCA's and LCA's remain at the same angle, and your steering point is moved away from your wheel center. When you lower with the torsion bars, the angle of the UCA's and LCA's change. When the UCA's are parallel to the ground, your camber curve is entirely favorable. And upward deflection of the UCA adds negative camber to the wheel, which improves handling. The roll center is also quite low at that point.

So, instead of spending $500 on drop spindles, buy a set of torsion bars and offset bushings and do it right for less.

This is how my Duster was sitting when the wheel arch was at 25 1/8". I've lowered it another 1/4" since then, and may go a little lower before I'm done. Stock spindles, stock LCA's, and the 3/8" bumpstop I linked earlier. I do have tubular UCA's to clear my 18x9" rims in the front. My ride height will end up being dictated by the 275/35/18's I have up front, I won't be able to lower it as much as vntnd to tuck the wheels because the tires are too close the fenders. I'd also probably run out of clearance to the top of the inner fender, with 25.7" tall tires I don't have much vertical clearance.

Thank you for the good info. Nice work on the cars!

What's the BS and spacing on the Duster (picture looks like there might be a spacer)?

What rotors/calipers are you running on the Duster?

Thanks,

Ron in Long Beach, CA

What's the BS and spacing on the Duster (picture looks like there might be a spacer)?

What rotors/calipers are you running on the Duster?

Thanks,

Ron in Long Beach, CA

Thank you for the good info. Nice work on the cars!

What's the BS and spacing on the Duster (picture looks like there might be a spacer)?

What rotors/calipers are you running on the Duster?

Thanks,

Ron in Long Beach, CA

Thanks!

There's a 5mm spacer on the Duster, what I think you're actually seeing is the aluminum hub. The brakes are Dr. Diff's 13" cobra-style kit. The offset on the rims is 35mm, but compared to a regular 73+ rotor the effective spacing is about 25mm (+5mm spacer, +3/16" offset on the rotor kit). So backspace on the 18x9's is effectively 6". The bottom front corner of the fender is pushed out a bit, I extended the bumper-to-fender brace to clear the tires. Its a lot tire up front.

1970Duster

Well-Known Member

- Joined

- May 30, 2010

- Messages

- 6,644

- Reaction score

- 215

Interesting

So, I should probably clarify and say the drop spindles aren't 100% unnecessary. I get a little carried away sometimes. ;)

If you want to lower the car more than you want to stiffen the torsion bars to compensate, you would need to use drop spindles to lower the car without constantly hitting the bump stops.

BUT, that has other problems. You do lower the car while maintaining the amount of available suspension travel with the drop spindles. That's assuming you lower the car a full 2", otherwise you're actually increasing the amount of available travel. But that travel is added everywhere. So, the suspension can travel an additional 2" up relative to the body. On my car, that would absolutely mean that my tires would hit the inner fenders if they used all of that travel. That would likely go for all of the 67-76 A-bodies, I know 72BBSwinger actually has scrubbed the tops his tires on lowest section of inner fender well on his car (without drop spindles). The only way to avoid that would be to run stiffer torsion bars and therefore reduce the amount of travel.

But, if you're going to run stiffer torsion bars, you might as well correlate the amount of drop with the amount of suspension travel you need. Sure, you might not be able to get as super low as you want without using stiffer bars than you'd like, but you might not be able to do that anyway. The amount of drop on my car isn't limited by the amount of suspension travel from the LCA to the frame, its limited by the amount of travel the tires have to the body, and that is a problem actually made worse by the drop spindles and softer bars. The only way around that would be to raise the "lowered" section of the inner fender up to where the tops of the fenders mount.

Another way to get around the suspension travel issue from the LCA to the frame is to use QA1's tubular LCA's. I had the CAP versions on my Challenger before the crappy CAP welds broke. The QA1's are much better pieces. Going to the tubular LCA allows almost 1" of additional travel because of their design, they have a much lower vertical profile. But, that STILL doesn't solve the problem of the tires hitting the body.

If you want to lower the car more than you want to stiffen the torsion bars to compensate, you would need to use drop spindles to lower the car without constantly hitting the bump stops.

BUT, that has other problems. You do lower the car while maintaining the amount of available suspension travel with the drop spindles. That's assuming you lower the car a full 2", otherwise you're actually increasing the amount of available travel. But that travel is added everywhere. So, the suspension can travel an additional 2" up relative to the body. On my car, that would absolutely mean that my tires would hit the inner fenders if they used all of that travel. That would likely go for all of the 67-76 A-bodies, I know 72BBSwinger actually has scrubbed the tops his tires on lowest section of inner fender well on his car (without drop spindles). The only way to avoid that would be to run stiffer torsion bars and therefore reduce the amount of travel.

But, if you're going to run stiffer torsion bars, you might as well correlate the amount of drop with the amount of suspension travel you need. Sure, you might not be able to get as super low as you want without using stiffer bars than you'd like, but you might not be able to do that anyway. The amount of drop on my car isn't limited by the amount of suspension travel from the LCA to the frame, its limited by the amount of travel the tires have to the body, and that is a problem actually made worse by the drop spindles and softer bars. The only way around that would be to raise the "lowered" section of the inner fender up to where the tops of the fenders mount.

Another way to get around the suspension travel issue from the LCA to the frame is to use QA1's tubular LCA's. I had the CAP versions on my Challenger before the crappy CAP welds broke. The QA1's are much better pieces. Going to the tubular LCA allows almost 1" of additional travel because of their design, they have a much lower vertical profile. But, that STILL doesn't solve the problem of the tires hitting the body.

momoparman

MOISMYHOME

BEWARE of the change in track width. If your using aftermarket brakes with big ball joint A arms your track width will increase by around 3/4" on each side. This makes the wheels sit out towards the lips and causes all kinds of issues with finding the correct back spacing for wheels.

If you go that route better do some measuring before you order anything and be prepared to find that many manufacturers will not be able to supply what you need.

Steel rims may be different but alloys will be a beech.

Notice 72nblus wheels and how far they stick out on the sides. He cannot lower his car any more or the tire will rub. I am using his set up as an example so you see how close they can come to the lip. No dis to 72's set up.

Go see my nightmare.

http://www.forabodiesonly.com/mopar/showthread.php?t=122153&page=11

Post #254 shows the car before I had custom hubs made. The wheels are 17x7 with 4.5" bs. That was the most back space I could find in an aluminum wheel both custom and off the shelf. That's why I had to do the hub. Unless I wanted tuner style wheels which I did not. The tuner styles have more aggressive back space typical of what would be needed on a fwd car.

Notice starting at post #263 what transpires and pics of the finished and working model.

Measure twice and spend $ once.

Good luck.

If you go that route better do some measuring before you order anything and be prepared to find that many manufacturers will not be able to supply what you need.

Steel rims may be different but alloys will be a beech.

Notice 72nblus wheels and how far they stick out on the sides. He cannot lower his car any more or the tire will rub. I am using his set up as an example so you see how close they can come to the lip. No dis to 72's set up.

Go see my nightmare.

http://www.forabodiesonly.com/mopar/showthread.php?t=122153&page=11

Post #254 shows the car before I had custom hubs made. The wheels are 17x7 with 4.5" bs. That was the most back space I could find in an aluminum wheel both custom and off the shelf. That's why I had to do the hub. Unless I wanted tuner style wheels which I did not. The tuner styles have more aggressive back space typical of what would be needed on a fwd car.

Notice starting at post #263 what transpires and pics of the finished and working model.

Measure twice and spend $ once.

Good luck.

BEWARE of the change in track width. If your using aftermarket with big ball joint A arms your track width will increase by around 3/4" on each side. This makes the wheels sit out towards the lips and causes all kinds of issues with finding the correct back spacing for wheels.

If you go that route better do some measuring before you order anything and be prepared to find that many manufacturers will not be able to supply what you need.

Steel rims may be different but alloys will be a beech.

Notice 72nblus wheels and how far they stick out on the sides. He cannot lower his car any more or the tire will rub.

The track width does change going from SBP brakes to LBP brakes, that is absolutely true.

But I want to correct something you said which is completely incorrect. My wheels stick out that far because that's where I put them, it's not because of the additional track width of the LBP brakes. That's where they HAVE to be in order to clear the frame at full lock. My front tires are 275/35/18's, and they sit on 9" rims. In fact, I had to add 5mm spacer on top of the added track width in order to keep my tires off of my frame. And my 13" rotors add an additional 3/16" to the track width, even compared to the 73+ LBP rotors. But I knew that when I bought my rims, which is why they're 18x9's with a 35mm offset. If I'd needed the wheels further in, I would have bought rims with more offset. As far as lowering, yes, I may be as low as I can go because of the fender clearance. But, if I roll the fender lips (like I'm planning), the next thing I hit will be the inner fenders. I would guess that will be in less than a 1/2" in ride height from where I am right now, at the absolute most. Honestly, that will probably become an issue at about the same ride height where I start hitting the fenders.

All you have to do is know what your track width change will be for the brakes that you choose, and properly compensate for that with the offset of your wheels. Custom hubs are unnecessary unless you want to run rims that have less offset than what you need for your car.

vntned

Well-Known Member

All good points! The key here is to come up with a plan on what your goals are for the car. If you want low and soft, low and super firm, is killer handling your goal or are you just going for looks, what brakes you want, what width/height wheel and tire you wanna run, etc.!

My car is purely a driver, so drop spindles and a less aggressive spring rate works great for what my goal is for the car. I wanted the car to be in the weeds and still offer a more comfortable ride. I didn't build it as a badass G machine, just a cool looking daily driver.

The badass Duster above is obviously built for ultimate performance! Giant brakes, killer suspension, aggressive wheel and tire combo, etc.! That car serves a different purpose than mine was intended too. Therefore the choice in components is completely different than what works for my car.

Figure out what you want from the car, then pick your parts appropriately!

My car is purely a driver, so drop spindles and a less aggressive spring rate works great for what my goal is for the car. I wanted the car to be in the weeds and still offer a more comfortable ride. I didn't build it as a badass G machine, just a cool looking daily driver.

The badass Duster above is obviously built for ultimate performance! Giant brakes, killer suspension, aggressive wheel and tire combo, etc.! That car serves a different purpose than mine was intended too. Therefore the choice in components is completely different than what works for my car.

Figure out what you want from the car, then pick your parts appropriately!

Looking at it you would never know that this 63 has 2'' drop spindles(FatMan Fab).

Steel wheels, You should be ok with 15x6. These were 14x5.5 with 195/70/14 front,73 up factory disc brakes and 15x7 rears 205/75/15.Big Bolt all around. Just a driver. Why ? they were free hand me downs from a friend that went a different direction with his project.

Steel wheels, You should be ok with 15x6. These were 14x5.5 with 195/70/14 front,73 up factory disc brakes and 15x7 rears 205/75/15.Big Bolt all around. Just a driver. Why ? they were free hand me downs from a friend that went a different direction with his project.

Attachments

momoparman

MOISMYHOME

"My wheels stick out that far because that's where I put them"

I know what your set up is and that's why I mentioned that I was using the pic as an example of how it would look. Meaning how it would look if you set it up not considering the change in track width. Your pic shows clearly that there is no room to lower the car without the tire hitting the fender. No dis as I mentioned above. If you recall you and I both learned a lesson on my wife's car. I still have those unused brackets you said would work....

He wants 2" drop so he can presumably lower his car so the tire is under the fender and he can still turn the wheels to full lock. If you don't plan or cant find the right rim your f'd. if you go to 73 up a-arms you will have to plan for that increase in track width and find something more like a 17x7 with 5.25" bs. I couldn't find anything in a 5 spoke old school style with that bs.

I know what your set up is and that's why I mentioned that I was using the pic as an example of how it would look. Meaning how it would look if you set it up not considering the change in track width. Your pic shows clearly that there is no room to lower the car without the tire hitting the fender. No dis as I mentioned above. If you recall you and I both learned a lesson on my wife's car. I still have those unused brackets you said would work....

He wants 2" drop so he can presumably lower his car so the tire is under the fender and he can still turn the wheels to full lock. If you don't plan or cant find the right rim your f'd. if you go to 73 up a-arms you will have to plan for that increase in track width and find something more like a 17x7 with 5.25" bs. I couldn't find anything in a 5 spoke old school style with that bs.

-