100VALIANT

Active Member

My engine is going to be around 500-525 hp with 11.0:1 compression and Aluminum heads. A bit too much for California 91.

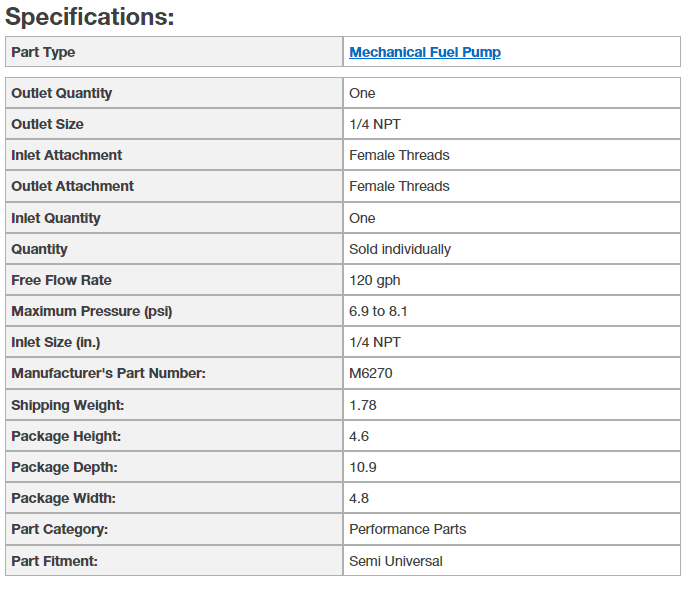

It'll be 90% street driven so I am thinking about going to e85 but it would be nice to use a mechanical pump like the Carter M6270 to avoid wiring and a battery disconnect when I do make some passes in it.

The Carter is a 120GPH pump. Taking out the 30% loss it'll be closer to 80 gph. I am using a RobbMc fuel pick up with -08 pick up, a -08 PTFE hose and would thread an AN in to the Pump. I know it's only a 1/4 NPT inlet. Has anyone seen this or done similar?

It'll be 90% street driven so I am thinking about going to e85 but it would be nice to use a mechanical pump like the Carter M6270 to avoid wiring and a battery disconnect when I do make some passes in it.

The Carter is a 120GPH pump. Taking out the 30% loss it'll be closer to 80 gph. I am using a RobbMc fuel pick up with -08 pick up, a -08 PTFE hose and would thread an AN in to the Pump. I know it's only a 1/4 NPT inlet. Has anyone seen this or done similar?