I've viewed the sticky video and the '65 FSM on adjusting the shift linkage rods. The video and the FSM only show the B body linkage (not the A which is different), but both require the use of a special tool to hold the Hurst shift levers at neutral. Later shifters use the alignment hole to insert a rod or screwdriver to hold them in neutral, and then the rods are adjusted in or out until they fit the neutral position shift levers on the trans. How do you hold the Hurst shifter levers in dead neutral on the early shifters without the special tool?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Early A833 4 speed linkage adjustment help

- Thread starter Bob Jasinski

- Start date

-

Does your early shifter have a hole in it for the alignment pin. If it does use a bolt the right diameter.I've viewed the sticky video and the '65 FSM on adjusting the shift linkage rods. The video and the FSM only show the B body linkage (not the A which is different), but both require the use of a special tool to hold the Hurst shift levers at neutral. Later shifters use the alignment hole to insert a rod or screwdriver to hold them in neutral, and then the rods are adjusted in or out until they fit the neutral position shift levers on the trans. How do you hold the Hurst shifter levers in dead neutral on the early shifters without the special tool?

and How Early? Mines a '65 with the Ball and Trunnion Shaft and it has the Hole thru the Hurst Shifter.

The "special tool" is a 1/4" drill bit out of your tool box.

I've viewed the sticky video and the '65 FSM on adjusting the shift linkage rods. The video and the FSM only show the B body linkage (not the A which is different), but both require the use of a special tool to hold the Hurst shift levers at neutral. Later shifters use the alignment hole to insert a rod or screwdriver to hold them in neutral, and then the rods are adjusted in or out until they fit the neutral position shift levers on the trans. How do you hold the Hurst shifter levers in dead neutral on the early shifters without the special tool?

A lot of the OEM Hurst A-Body shifters do not have the Reverse lever drilled, up to 1971. There is a metal rectangle sticking down on the housing, front and rear that will also "index" the neutral position for the shifter. It will usually be within one turn of the neutral position in either case. In other words, check neutral position and be prepared to add or subtract a turn on the rod adjuster to hit the sweet spot.

I tried putting through Allen wrenches through the small hole at the bottom, they go in part way, but looks like the reverse lever is blocked. All FSM says is special tool, but basically what the tool does is align the levers together, except reverse, doesn't make sense to me.

![IMG_9511[1].JPG IMG_9511[1].JPG](https://www.forabodiesonly.com/mopar/attachments/img_9511-1-jpg.1716111800/)

![IMG_9510[1].JPG IMG_9510[1].JPG](https://www.forabodiesonly.com/mopar/attachments/img_9510-1-jpg.1716111801/)

This ^^^A lot of the OEM Hurst A-Body shifters do not have the Reverse lever drilled, up to 1971. There is a metal rectangle sticking down on the housing, front and rear that will also "index" the neutral position for the shifter. It will usually be within one turn of the neutral position in either case. In other words, check neutral position and be prepared to add or subtract a turn on the rod adjuster to hit the sweet spot.

I tried Rusty's suggestion (thanks Rusty) with the 1/4" bit and it lines up and locks in 1-2, 3-4, but not reverse. There's no hole in reverse, and it is narrower than the other two. How do you index reverse?

Sho nuff. Read post #5.I tried Rusty's suggestion (thanks Rusty) with the 1/4" bit and it lines up and locks in 1-2, 3-4, but not reverse. There's no hole in reverse, and it is narrower than the other two. How do you index reverse?

So, for these early shifters, there really is no way to hard index reverse without the special tool. It's trial and error, I get it.Sho nuff. Read post #5.

Irving Santiago

Member

A 1/4" short allen hex key will suffice also...The "special tool" is a 1/4" drill bit out of your tool box.

I would stick in a drill bit or hex key and align 1-4 and then go to Reverse. Unhook the reverse linkage and shift the transmission into reverse. Shift the shifter into reverse and adjust the linkage. That should be damn close.

Toolman, I did as you suggested. Worked pretty well, went into reverse fine, but when fast shifting into 2nd and 4th it would bang against the reverse lever, so I backed it off two turns and the banging went away. Reverse adjustment doesn't seem as finicky as 1-4.I would stick in a drill bit or hex key and align 1-4 and then go to Reverse. Unhook the reverse linkage and shift the transmission into reverse. Shift the shifter into reverse and adjust the linkage. That should be damn close.

No way to index reverse WITH the tool I think you meant. Which would be correct, since there's no hole for the tool to engage.So, for these early shifters, there really is no way to hard index reverse without the special tool. It's trial and error, I get it.

Rusty,No way to index reverse WITH the tool I think you meant. Which would be correct, since there's no hole for the tool to engage.

Have a look at this page (21-19), (Fig 38) from the FSM, and step (3) "Slide tool C-3951 over the levers, Inserting center pin through the first two levers (Fig 38). Tighten set screw securely. (this aligns the 3 levers in the gear shift control assembly, and holds them in neutral position)".

So, the book says 3 levers, but I find it confusing as to how it actually works. Notice the special tool slid under the shifter. What makes it even more confusing is that this is a B body illustration, no A body illustration shown. A body has the taller shift stub and a hole at the bottom of the shifter this one does not have.

The shifters are basically the same, A-Body and B-Body. The B-Bodies came with the shift stop bolts and the shorter handle stub/tower. There are indexing flats on all three levers that match the flats on the shifter housing. You can use a crows foot open end wrench or anything to run along the edges of the housing and the matching flats of the three shifter levers. It is a hard index.

694spd

Well-Known Member

Here is a picture that I took a few years ago showing the factory Hurst installed shifter from my 69 GTS on the left, next to a Hurst aftermarket Comp Plus shifter on the right. The picture shows an alignment pin that I installed through all three levers on the Comp Plus shifter, but hitting the undrilled reverse lever on the factory Hurst shifter. See "blue arrow"

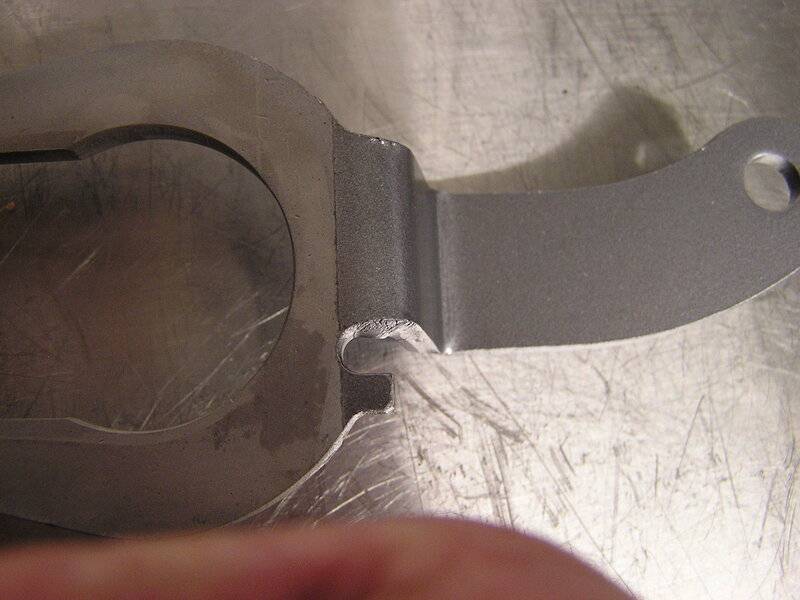

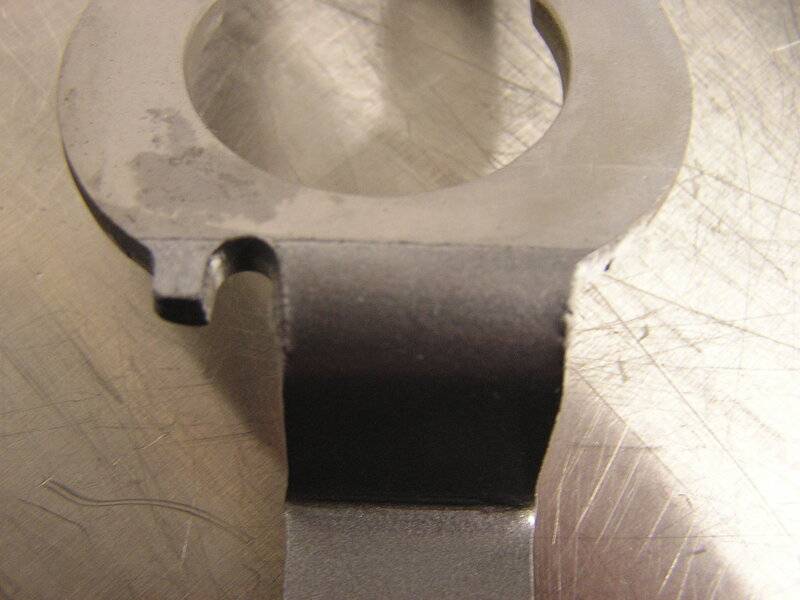

First off, I have it adjusted and working fine, so there's that, but I've come to understand that while the shifters are all "basically the same", many variations have been made over the years that do have significant differences when it comes to adjusting them. As several have mentioned the reverse lever had no hole to index to from '64 to '69 or so, but the very early shifter, like I have in my '65 project, the reverse lever is not the same width as the other two levers. My 1-2 and 3-4 levers measure about 1.25" wide, while the reverse measures about .884" wide. So, what do you index the reverse lever to? The front of the other two or the rear? Middle? Setting 1-4 levers using the 1/4" drill in the hole, and using Toolman's suggestion to engage the R lever on the transmission and then move the shifter to reverse then setting the rod, worked. This picture shows the R lever with the other two behind it, you can see the width difference. It appears that the R lever aligns with the rear of the other two, at least that's how it ended up on mine. Matching flats of the three shifter levers front and back not possible due to width differences. No hard index without special tool, or knowing to line up the rears of all three.

The hard index is about .19 thick and about 1.255 wide x 2.300 deep. That is what the factory tool holds. Notice the raised part at the bottom of the housing and the "extra" material on the reverse lever that makes the width come out to the 1.255 inches to match the rest of the levers. Both the shifters are early 64-65 Hurst A-Body 4 speed shifters.

The hard index is about .19 thick and about 1.255 wide x 2.300 deep. That is what the factory tool holds. Notice the raised part at the bottom of the housing and the "extra" material on the reverse lever that makes the width come out to the 1.255 inches to match the rest of the levers. Both the shifters are early 64-65 Hurst A-Body 4 speed shifters.

View attachment 1716117182

View attachment 1716117183

View attachment 1716117184

View attachment 1716117185

View attachment 1716117186

View attachment 1716117187

View attachment 1716117188

View attachment 1716117189

View attachment 1716117190

View attachment 1716117191

66FS, Thanks for the post. I currently have my transmission shifting properly, by using the 1/4" drill bit for 1-4, adjusting and installing the 1-4 rods into the neutral position 1-4 trans levers. To adjust the R rod, I removed the drill bit, put the shifter and trans lever in R, adjusted the R rod until it fit and reclipped. It worked that way without jams but noticed the 1 and 3 shifts banged a bit on the R trans lever so backed off the R rod one or two turns and it works fine.

I looked at my shifter and do see the R notch in the R shifter lever (as shown in your pictures) so decided to remove the R rod, and with the shifter in neutral and the R rod disconnected, I was able to install the 1/4 " bit into all 3 notches by moving the R lever forward. With the R trans lever in neutral, I found I had to lengthen the R rod quite a bit to get the R rod to fit the R lever, but I went ahead with the adjustment with the bit in place and refit and clipped the R rod to the trans lever. Removed the 1/4" bit and tried the shifter and it was jammed. Could not get it into any gear.

I put it back the way it was. I suppose it's possible that I have the wrong R rod, but I don't think so, does this R rod look wrong? It is a bit close to the crossmember, but there is no weight on the crossmember, so the crossmember hangs down here farther than it will be in the car.

Last edited:

You should be good. Your reverse rod looks OK. On those shifters, you use the lower tabs on the housing inside and outside and the outside of the tabs on the 3 levers to index neutral. The 1/4 in holes in the 1st and 2nd lever and the 3rd and 4th lever are not the index features. They can not align with the rear 1/4 in hole in the housing. That is why the factory tool indexes the outside 1.255 step on all three levers with the 1.255 tabs on the housing. See the first four pictures in post #19 above.

66fs: you wrote "The 1/4 in holes in the 1st and 2nd lever and the 3rd and 4th lever are not the index features. They can not align with the rear 1/4 in hole in the housing" I don't quite understand why you state that. When the 1/4" drill is inserted into the 1-2,3-4 shifter levers, to the hole in back, (R lever pulled back out of the way) the levers DO align properly with the reference tabs, I just did this on mine to confirm. Why do you say that the hole is not a valid index reference?You should be good. Your reverse rod looks OK. On those shifters, you use the lower tabs on the housing inside and outside and the outside of the tabs on the 3 levers to index neutral. The 1/4 in holes in the 1st and 2nd lever and the 3rd and 4th lever are not the index features. They can not align with the rear 1/4 in hole in the housing. That is why the factory tool indexes the outside 1.255 step on all three levers with the 1.255 tabs on the housing. See the first four pictures in post #19 above.

So, the Comp Plus is Not a Factory Shifter but an AfterMrkt?Here is a picture that I took a few years ago showing the factory Hurst installed shifter from my 69 GTS on the left, next to a Hurst aftermarket Comp Plus shifter on the right. The picture shows an alignment pin that I installed through all three levers on the Comp Plus shifter, but hitting the undrilled reverse lever on the factory Hurst shifter. See "blue arrow"

View attachment 1716112308

66fs: you wrote "The 1/4 in holes in the 1st and 2nd lever and the 3rd and 4th lever are not the index features. They can not align with the rear 1/4 in hole in the housing" I don't quite understand why you state that. When the 1/4" drill is inserted into the 1-2,3-4 shifter levers, to the hole in back, (R lever pulled back out of the way) the levers DO align properly with the reference tabs, I just did this on mine to confirm. Why do you say that the hole is not a valid index reference?

How do you get the reverse lever with no hole?

I think we're going in circles here. With the R rod disconnected and the R shifter lever pulled back, the path is clear for the bit to pass through the 1-2, 3-4 lever holes to the rear hole, so the holes ARE an index feature for 1-2, 3-4, NOT Reverse. You get reverse rod adjustment by either 1. placing the shifter and trans lever in reverse, and adjust the R rod to fit. Or 2. In neutral, line up the top part of the R shift lever with the same tabs extending down that index the to 1-2, 3-4 levers (which are also indexed by way of inserting the 1/4" drill bit See post #22). Just a side note, I have used both methods for adjusting the R rod, and in both cases, I had to shorten the R rod by one or two turns to eliminate a banging against the R trans lever when going into 2nd or 4th. It's possible my R rod is off a little causing this.How do you get the reverse lever with no hole?

-