What would you guys recommend for a valve job on a 440 that will never see more than .450 valve lift or 4500 rpms? Valves are tiny at 1.88 and 1.50. Using 413 industrial heads and fuel economy is primary concern.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Edelbrock 2.055 (30 degree back-cut) testing

- Thread starter pittsburghracer

- Start date

-

I ran into this video the other day and i learned quite a bit about reversion and how cam events and seat angles change things.. Of course it's youtube and he could be full of crap though

He has a good rep before the internet came around.

I had never heard of him.. just came up when i was researching things.. trying to learn so i make educated mistakesHe has a good rep before the internet came around.

Well that’s an excellent way of doing things IMO. Learn what you can, keep an open mind, try and listen more and talk less, keep the mental library open and fill it from as many sources as you can.

I’ve heard of this fella a good while back. He definitely has some odd things I never heard of before and picked up on.

I’ve heard of this fella a good while back. He definitely has some odd things I never heard of before and picked up on.

Charrlie_S

Well-Known Member

I'm referring to a standard old school basic stock valve job. The only way to get the correct seat width, is with a 3 angle (or more) cut.There are far better valve jobs out there than the standard 15 degree cut.

Rat Bastid

Dunamis Metron

I'm referring to a standard old school basic stock valve job. The only way to get the correct seat width, is with a 3 angle (or more) cut.

I agree, but you don’t have to use a 15 degree difference to correct the seat width. You can use 8 or 10 degrees.

But with a stone it’s a bit of a ***** to get all the cuts the same width.

That’s why I prefer do to my valve jobs with a forming tool.

A little bit here and a little bit there.This is only about what I gained with a 30 degree backcut on the valve.

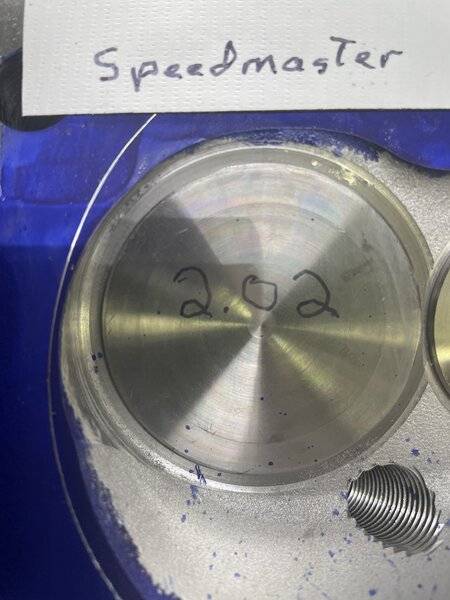

Last couple sets of used Edelbrock heads I’ve done I’ve been down 10-15 cfm at .300 not hitting my target 200cfm. My last set of Speedmaster heads I hit [email protected] so I opened up a new set of Speedmaster heads to do a quick comparison. The chamber is clearanced more on the intake valve so with the 2.055 valve it’s really tightening things up. Here’s a few quick pictures showing the difference. Both heads laid out with the same gasket.

Brian Hafliger

Well-Known Member

So why do cams with more overlap tend to make more power?Anything that increases reversion will inhibit cylinder fill.

Brian Hafliger

Well-Known Member

I ran into this video the other day and i learned quite a bit about reversion and how cam events and seat angles change things.. Of course it's youtube and he could be full of crap though

Ben knows a thing or 2....

Brian Hafliger

Well-Known Member

Curious, do you usually not use a back cut? Where are you at on the .300# and what do you think it should be?I’m struggling with my .300 flow number for the first time in years but that’s for another post. While searching for that lift issue I had a few extra minutes before I quit so I did back to back tests with two brand new 2.055 Ferrea intake valves. I’m sure I did this many many years ago but I keep better notes now so I will add this to them. I had always heard it help low to mid numbers and may hurt high lift numbers but this is the gain from .100-.600 lift.

.100——-+6

.200——-+7

.300——-+8

.350——-+7

.400——-+5

.450———+5

.500——-+3

.550———+4

.600——-+4

- Joined

- Dec 31, 2005

- Messages

- 8,691

- Reaction score

- 4,682

What if you need that to improve the vaporization of the mixture because the carb you use produces a droplet size that needs it?So why do cams with more overlap tend to make more power?

I would recommend using different heads.What would you guys recommend for a valve job on a 440 that will never see more than .450 valve lift or 4500 rpms? Valves are tiny at 1.88 and 1.50. Using 413 industrial heads and fuel economy is primary concern.

Curious, do you usually not use a back cut? Where are you at on the .300# and what do you think it should be?

I always have used a 30 degree backcut but just did some no backcut testing to pass on and for my records. I took a 4-5 year break from doing anything for customers because number one I was only charging 400.00-500.00 per job for mostly friends and burned myself out. Of course when you do your own stuff I do more testing and do my own thing. On the new set of 2.08

Valve heads I’m doing for myself I’m at [email protected] and pushing [email protected]. These heads are to hopefully replace an old set of open chamber heads I’m running that I did probably over 10 years ago. Well the set of Speedmaster heads I just did easily hit [email protected] this set I struggled to hit [email protected] on a set of used Edelbrock heads that had a little work done to them previously. I was ok with that because he’s running a .645 lift roller cam and they recovered nicely at .350 and ended up over 308 cfm with a 2.055 valve. Now another set of used Edelbrock heads with a little work done and I had to really work at getting him [email protected] and was trying my hardest to up the lower numbers as he’s only running a .565 cam with the heads again nicely over 300 with a 2.055 valve. That’s what made me look at the chamber of the two heads. The speedmaster chambers are definitely clearanced better than the Edelbrock heads which in turn produce better at .300

Lift.

Last edited:

Sounds like the Speedmasters are a better choice for low lift and lower rpm.I always have used a 30 degree backcut but just did so no backcut testing to pass on and for my records. I took a 45 year break from doing anything for customers because number one I was only charging 400.00-500.00 per job for mostly friends and burned myself out. Of course when you do your own stuff I do more testing and do my own thing. On the new set of 2.08

Valve heads I’m doing for myself I’m at [email protected] and pushing [email protected]. These heads are to hopefully replace an old set of open chamber heads I’m running that I did probably over 10 years ago. Well the set of Speedmaster heads I just did easily hit [email protected] the i struggled to hit [email protected] on a set of used Edelbrock heads that had a little work done to them previously. I was ok with that because he’s running a .645 lift roller cam and they recovered nicely at .350 and ended up over 308 cfm with a 2.055 valve. Now another set of used Edelbrock heads with a little work done and I had to really work at getting him [email protected] and was trying my hardest to up the lower numbers as he’s on running a .565 cam with the heads again nicely over 300 with a 2.055 valve. That’s what made me look at the chamber of the two heads. The speedmaster chambers are definitely clearanced better than the Edelbrock heads which in turn produce better at .300

Lift.

So why do cams with more overlap tend to make more power?

Gonna give it a shot and see how wrong i am

More overlap allows a better cyl fill which means more cyl pressure allowing more power, up to a point in which reversion would cause more issues and loss of power. Also depending on the combo/port design less overlap would make more power since the ports allow for better cylinder filling with less overlap needed, so having more overlap would cause those reversion issues sooner.

I think that might be correct.. most of it was in the video i posted above though.. There is soo much stuff to cam selection that it's turning into black magic for me.. for my 318 using vizards method i come out with a 109 LSA.. that's bout all i've come up with so far.

Sounds like the Speedmasters are a better choice for low lift and lower rpm.

Not saying the Edelbrock heads can’t be fixed but if you have a customer like I’m doing this set for right now he’s trying to keep his compression as high as he can because he’s borderline low to start with.

Rat Bastid

Dunamis Metron

Gonna give it a shot and see how wrong i am

More overlap allows a better cyl fill which means more cyl pressure allowing more power, up to a point in which reversion would cause more issues and loss of power. Also depending on the combo/port design less overlap would make more power since the ports allow for better cylinder filling with less overlap needed, so having more overlap would cause those reversion issues sooner.

I think that might be correct.. most of it was in the video i posted above though.. There is soo much stuff to cam selection that it's turning into black magic for me.. for my 318 using vizards method i come out with a 109 LSA.. that's bout all i've come up with so far.

109 LSA with what heads?

Trick flow 190's which are 2.02 intake109 LSA with what heads?

On a 318? Overbored?Trick flow 190's which are 2.02 intake

I come up with 110.

109.81 @ a 030 - 318.

On a 318? Overbored?

I come up with 110.

109.81 @ a 030 - 318.

Ah, i was just using vizards thing... he figures using 10.5:1 compression i am guesstimating mine will end up around 9.5:1 (don't have everything to figure it yet) and he said to lower the LSA if your compression is a little lower than his formula. Still trying to learn before i actually buy anything, i have a few months to go still. At the time i will probably be asking on here for recommendations anyway

Gotcha! Best wishes in your build.

Thanks and i'm not doubting you at all.. i trust your opinion, just figuring things out.. I have decided on manual disc/drum brakes so not too worried bout vacuum or idle quality too much at this point. Kind of funny how "just wanna build a cruiser to drive" changes pretty quickly..Gotcha! Best wishes in your build.

Lonewolf3165

Living the Dream!

The ram effect of the rushing air flow.So why do cams with more overlap tend to make more power?

-