Agent_Orange

Well-Known Member

I've worn out the search bar to the point where I'm seeing the same posts over and over, not finding much chatter about this issue, so it's safe to say I messed up somewhere.

318 w/ vac advance, eddy 1406, mild cam with original springs, headers, 2.5" exhaust w/ mufflers, 727, 3.73 rear.

Timing done with an Innova 3568 dial back light.

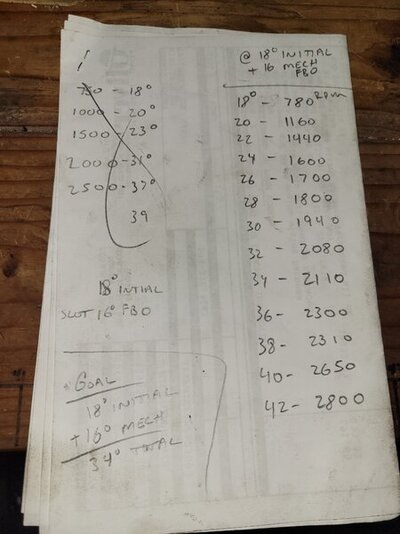

After timing test, the engine wants 18* initial, and 34* mechanical. Bought a FBO plate and spring kit, assembled the distributor with both light springs from kit and the plate set on the 16* tabs.

dropped the dizzy in, warmed the engine up and locked initial in at 18*. Next, with vac advanced disconnected, I mapped my curve by setting my dial back at 20* jot down rpm, then 22*, 24* all the way until I ran out of advance. I hit my target of 34* total (initial+mech) @ 2110 rpm, yet the advance kept going. The engine quit advancing 42* @ 2800 rpm. 8 degrees more than the fbo plate should have allowed.

I read one thread on here from a while ago with a similar issue of over advancing with a fbo plate, and the verdict was to replace the ignition module, but I didn't have this issue a few days ago when I tested the stock distributor with that same ignition.

318 w/ vac advance, eddy 1406, mild cam with original springs, headers, 2.5" exhaust w/ mufflers, 727, 3.73 rear.

Timing done with an Innova 3568 dial back light.

After timing test, the engine wants 18* initial, and 34* mechanical. Bought a FBO plate and spring kit, assembled the distributor with both light springs from kit and the plate set on the 16* tabs.

dropped the dizzy in, warmed the engine up and locked initial in at 18*. Next, with vac advanced disconnected, I mapped my curve by setting my dial back at 20* jot down rpm, then 22*, 24* all the way until I ran out of advance. I hit my target of 34* total (initial+mech) @ 2110 rpm, yet the advance kept going. The engine quit advancing 42* @ 2800 rpm. 8 degrees more than the fbo plate should have allowed.

I read one thread on here from a while ago with a similar issue of over advancing with a fbo plate, and the verdict was to replace the ignition module, but I didn't have this issue a few days ago when I tested the stock distributor with that same ignition.

learning

learning