Here’s something to chew on.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

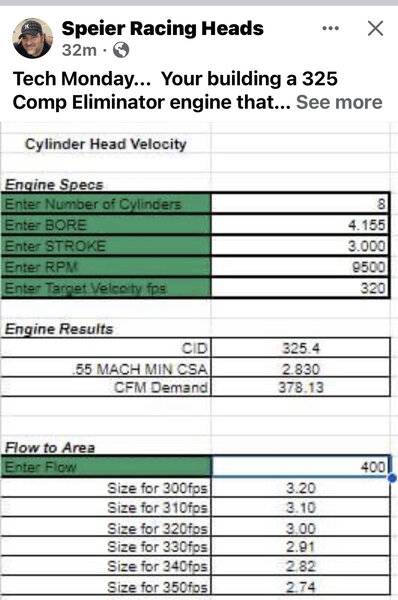

For the guys that like to play with numbers.

- Thread starter pittsburghracer

- Start date

-

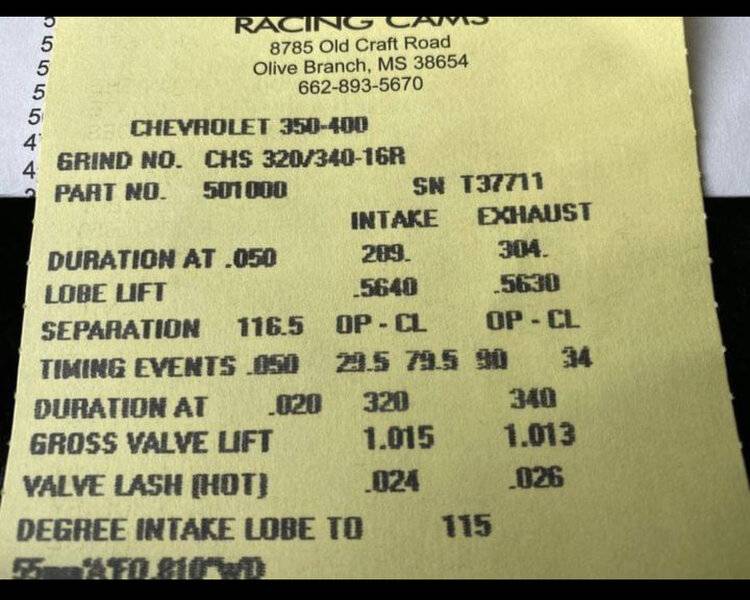

289@050?!?!

Enter the Rick Flare “WHOOOOOOOOO!!!!!!!”

Enter the Rick Flare “WHOOOOOOOOO!!!!!!!”

289@050?!?!

Enter the Rick Flare “WHOOOOOOOOO!!!!!!!”

As it says. Comp Eliminator. Lol

289@050?!?!

Enter the Rick Flare “WHOOOOOOOOO!!!!!!!”

How do you like the lift. I guess that’s a FuLL race cam.

Play with numbers? I like playin with boobs.

3/4 race cam. lolHow do you like the lift. I guess that’s a FuLL race cam.

Numbers won't get you slapped!

How do you like the lift. I guess that’s a FuLL race cam.

This is how I see it. And you already know this…. If your not lifting the valve up as much as the head flows your giving up HP. While it may not be a lot or needed to run the time or speed, it’ll be up to the end user to take full advantage of the cylinder heads available flow or not.

If the cylinder head only flows well to .550 and use a .410 lift cam, what are you leaving behind. Same on any lift cam and head. So what does his head flow? I don’t know. Let’s pretend it flows awesome all the way up to a massive 1.00 mile inch lift and doesn’t nose over. It flows 250cfm @.570 & [email protected], [email protected], [email protected].

Untapped power…..

His rules may dictate something?

Low lift isn’t taxing the valve train, so, IMO, that’s a plus for longevity.

Whatever works for him, you, me, the next guy on line, it’s all good.

What I think that cam will do is rocket the valve up and let it t there for a while and then slam shut. That ought to gobble down a bunch of air and fuel to get that thing whippin down the track.

From Bullet's Lobe List:

Adv. .050 .200 Lobe Lash Lobe Type

Intake : R320/564 320 289 213 0.5640 0.0093 CRS

Exhaust : R340/563 340 304 224 0.5630 0.0140 CRA

Lobe Type explanation:

(I don't think the lash to rocker ratio equation applies with this one!)

Adv. .050 .200 Lobe Lash Lobe Type

Intake : R320/564 320 289 213 0.5640 0.0093 CRS

Exhaust : R340/563 340 304 224 0.5630 0.0140 CRA

Lobe Type explanation:

- The first letter is either "C" for a conventional shaped nose on the lobe, or "D" for a dwell nose. Dwell lobes are often used when there is a lift rule, such as NHRA stock classes. Dwell lobes are usually not well suited for higher RPM applications.

- The second letter is either "R" (RPM) for lobes suited for higher RPM applications or motors with numerically high rocker ratios, or "T" (Torque)for lobes suited for lower RPM or motors with numerically low rocker ratios.

- The third letter is either "S" for symmetrical lobes (opening and closing ramps the same), or "A" for asymmetrical lobes (opening and closing ramps different). Asymmetrical lobes usually have a slower closing rate to help prevent valve bounce.

(I don't think the lash to rocker ratio equation applies with this one!)

OldmanRick

Well-Known Member

Probably has a 245 head on it. Love to see the piston dome. Gotta love those willing to put that money into a Sportsman build these days.

Newbomb Turk

Well-Known Member

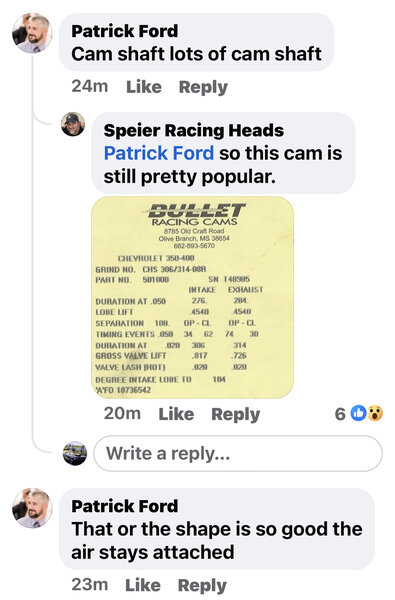

Speier really believes in those formulas, seen him battle other dudes over them, the others seem to see them as guidelines.

His stuff has set enough records that I can say his methods work.

dusterbing the peace

FABO pyrite member

I don’t have bookface, does he happen to post HP results? Would assume top secret stuff, but figured I’d ask. With approx 400 cfm targeted/port for 325ci, this thing is going to move whatever little comp car it’s bolted in! Dummy math is near 2.5hp/ci, which is only slightly more than your average bear can nab in a picanic basket.

I’ve not seen specs for these motors before…this is pretty fuggin cool. Thanks for sharing!

I don’t have bookface, does he happen to post HP results? Would assume top secret stuff, but figured I’d ask. With approx 400 cfm targeted/port for 325ci, this thing is going to move whatever little comp car it’s bolted in! Dummy math is near 2.5hp/ci, which is only slightly more than your average bear can nab in a picanic basket.

I’ve not seen specs for these motors before…this is pretty fuggin cool. Thanks for sharing!

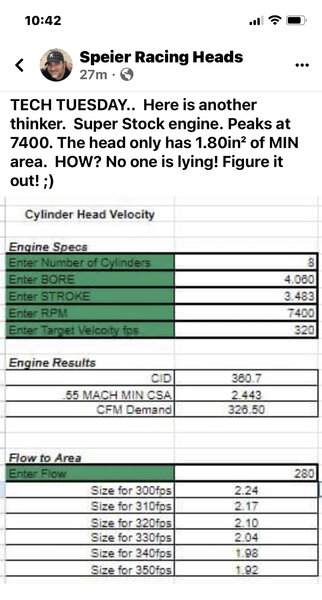

The discussions sometimes hit on horsepower numbers but he usually post pictures on techniques and formulas. You anti Facebook guys miss a lot of good info. I try to drag some over but it’s a small percentage of what’s out there. Here’s another formula he posted.

- Here,s some Speier's vids and formulas from his web site.

- Average_CSA = Port_Volume_CC / (Port_CenterLine_Length * 16.387)

- MIN CSA = (Bore x Bore x Stroke x RPM x .00353) / 613.8 (.55 MACH)

- Port_Volume_CC = Average_CSA * Port_CenterLine_Length * 16.387

- Port_CenterLine_Length = Port_Volume_CC / ( Average_CSA *16.387 )

- FPS = ( Flow_CFM * 2.4 ) / Average_CSA

- Flow_CFM = Average_CSA * FPS * .4166667

- Average_CSA = ( Flow_CFM * 2.4) / FPS

- cfm demand = cid x rpm x .0009785 / # of cylinders

Here’s another one he just posted.

@pittsburghracer have you ran your car through these formulas just to see ?

@pittsburghracer have you ran your car through these formulas just to see ?

No I have zero interest in this.

-