You will need the metal plate for the brim of your bezel. It attaches to the plastic bezel as heat shield/reinforcement only. It has no bearing on chassis ground path.

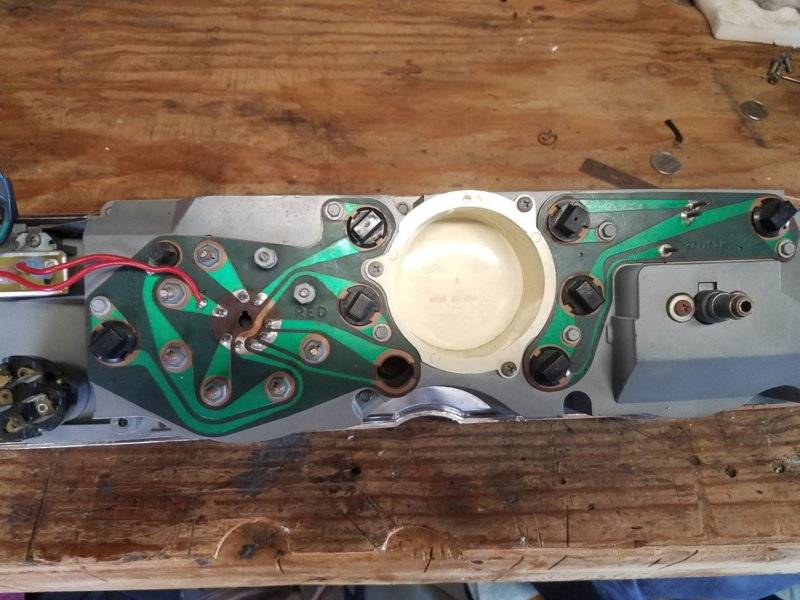

For bench testing you can alligator clip a ground wire anywhere on the pot metal housing. In the car... The best place to add a ground wire is at the bottom of the center pod. These are larger screws. Other screws are barely enough to hold the circuit board and we can over tighten to strip the threads in the pot metal. a ring terminal and toothed washer at one of those screws is a bad plan. So...About 4 inches of wire with a ring terminal and toothed washer under that screw at bottom of center pod. Male spade terminal other end. Another longer length of wire with female spade terminal attached provides disconnect, plug unplug like anything else ( less the amp gauge ). Route the other end of this wire to behind the left kick panel. Another ring terminal, toothed washer and a screw there.... Done. Pretty much the same way your heater case is grounded behind the right kick panel. everyone has their own way of doing things. some attach the ground wire to column support. Lowering the column detaches the ground just like pulling the panel out does.

Your oil and temp are common 2 post thermal range indicators. Ohms meter should so 20 ohms post to post. A 3 volt battery attached across should move the needle to about 1/2 the range.

Your 3 post fuel gauge is quite different. Ohms meter would have shown 20 ohms, 50 ohms, and 70 ohms from post to post but, Since someone has added the outboard limiter, I'll assume they followed the info found online, opened the gauge and bent the OEM/inboard limiters contact beam. If the insulation on that resistor wire is shorted to the beam and they didn't isolate the slither of metal on the back of the fuel gauge that grounds it to the housing, a short circuit may exist. (5 volts out of regulator follows that path as if it was another gauge).

If you shipped your circuit board, outboard regulator, and all 4 gauges to me, I could correct all of it and convert the amp gauge to volt gauge too. Ground for volt gauge incorporated to chassis ground wire described above. 12 volts on blue with white tracer would go to outboard regulator and volt gauge via wire leads. 12 volts would no longer enter the fuel gauge. Again, different ways of doing things. I could send that heat shield piece with its attaching hardware too. Your total cost depends on the condition of your gauges.

With a little luck you may find the oil and temp gauges good. Do they need screens cleaned and needles painted? What about the speedometer? That's why so many rally panel owners opted to just ship their entire inst' panel to me. So... do some testing if you want. Pm me if I can help.