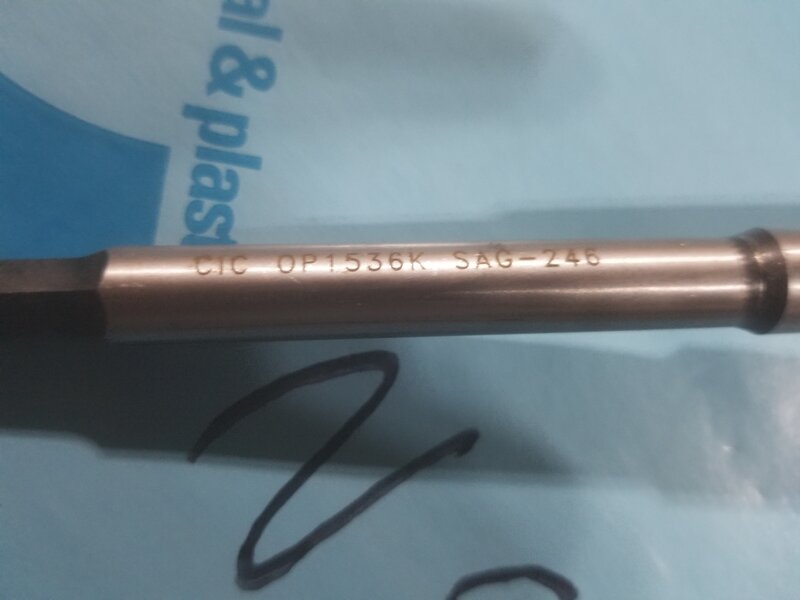

I am in the process of building a known to me good running 340. Upon disassembly, the engine reveled a high volume oil pump. I defaulted to a new hardened oil pump shaft because I do not know if the existing oil pump shaft is hardened as is required for a high volume oil pump. I am having second thoughts as to which of these 2 shafts may be better. I got a lead off of this site to a supposedly US built hardened shaft but I am having second thoughts as to if this a quality piece, Ya, the oil pump bushing is bragging about being made in the USA but the shaft has me perplexed.

The packaging has vague writing but the bushing is in a proud "made in USA" container. The new shaft has a heavier feel to it. I'll get some pics up with my phone.

The packaging has vague writing but the bushing is in a proud "made in USA" container. The new shaft has a heavier feel to it. I'll get some pics up with my phone.

Last edited: