Hi All,

Been a while since I sold my Duster due to good old life changes, but recently picked up a '82 W150 with what I was told was a LA based 408 in it. I got a ton of help from this group when I had my Duster, so figured it was a good place to start.

What I know about the motor:

Cam: Comp Cams 20-225-4 https://www.summitracing.com/parts/cca-20-225-4

Heads: Performer RPM 8077

Intake: RPM AirGap

Was told it had a forged crank, but still need to identify exactly whats in it.

Cool rig, pretty good shape, its swapped to a 5spd out of an early magnum. It seemed to be running strong when I parked it for the winter.

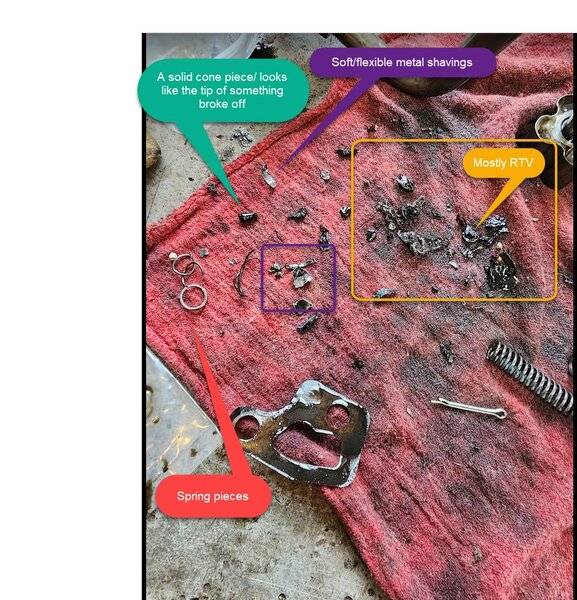

rear main had a pretty good leak so I tore the oil pan off and the fun begins. Quite a bit of RTV in the pan/pickup and some lovely remnants of a spring that I'm trying to identify and some other bits of some very soft metal along with small metal cone shaped piece. At this point I'm going to pull it for the ease of working on it and take a deeper look at things. Pressure relief spring/valve/cap all seemed intact. Any ideas of what I'm looking at here?

Been a while since I sold my Duster due to good old life changes, but recently picked up a '82 W150 with what I was told was a LA based 408 in it. I got a ton of help from this group when I had my Duster, so figured it was a good place to start.

What I know about the motor:

Cam: Comp Cams 20-225-4 https://www.summitracing.com/parts/cca-20-225-4

Heads: Performer RPM 8077

Intake: RPM AirGap

Was told it had a forged crank, but still need to identify exactly whats in it.

Cool rig, pretty good shape, its swapped to a 5spd out of an early magnum. It seemed to be running strong when I parked it for the winter.

rear main had a pretty good leak so I tore the oil pan off and the fun begins. Quite a bit of RTV in the pan/pickup and some lovely remnants of a spring that I'm trying to identify and some other bits of some very soft metal along with small metal cone shaped piece. At this point I'm going to pull it for the ease of working on it and take a deeper look at things. Pressure relief spring/valve/cap all seemed intact. Any ideas of what I'm looking at here?