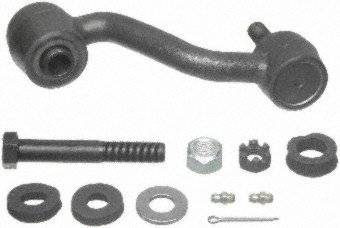

can anyone tell me how this idler arm works as far as in the bracket end? (shown here on the left). When installed, the metal 'tube' in there seems to just be fitted up against the bracket and rotates, metal on metal, in the bracket (the bottom end calls for a washer but still would be metal to metal there as well as top). I put the old one in a vise held by the tube part and tried to rotate it - the tube did not seem to rotate inside the fitting. Is that correct, and if that is the case, does grease get to the contact point? Is grease just for any side to side/up-down movement inside the fitting? appreciate any insight to this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

how does this idler arm work

- Thread starter Dave NEO

- Start date

-

What year car? As I work foggy memory, that looks to be for 68 and up vehicles. The one end is pinched between upper and lower brackets on "K" member by the bolt shown, the other end ( the taper ) goes into the center link, torque the nut to spec and insert cotter pin. The end pinched in the "K" member is a non greaesable joint, not to worry. Tighten the draw bolt when the steering wheel is centered, wheels pointing straight ahead

sorry yes, it's a '68 Barracuda- moog 7042 _ OK, I don't recall if I was careful aligning wheels before I torqued it. Maybe that is why steering wheel is off. there's a grease fitting on that bracket end so I wondered why/how it lubed anything. thnks for your comments.

Last edited:

dodge71demon

Well-Known Member

"Tighten the draw bolt when the steering wheel is centered, wheels pointing straight ahead" -- makes no difference how things are pointed it pivots at the K member has nothing to do with alignment just holds your center link in place in ratio to the pitman armWhat year car? As I work foggy memory, that looks to be for 68 and up vehicles. The one end is pinched between upper and lower brackets on "K" member by the bolt shown, the other end ( the taper ) goes into the center link, torque the nut to spec and insert cotter pin. The end pinched in the "K" member is a non greaesable joint, not to worry. Tighten the draw bolt when the steering wheel is centered, wheels pointing straight ahead

so sounds like I really can't loosen and adjust anything at ider if I understand correctly? maybe just drifting/pulling that side a little now cuz it needs alignment after new idler. Alignment seemed OK before replacing idler. thanks for any comments

Last edited:

Tighten it up tight, it has a spring loaded double tapered bushing to keep it tight and I doesn't mater where it is when you tighten it, it's not a rubber bushing that will spring back.

tighter steering wheel - slop gone - I think wheels each point outward a bit, and it feels a bit like that driving, so whatever that adjustment is....probably was last aligned with the worn out idler arm..

dodge71demon

Well-Known Member

I would venture to say your in need of a complete steering rebuild -- pretty easy the hardest parts would be the upper ball joints

rustycowll69

Well-Known Member

If I understand you correctly, the steering wheel centering, and the tires not pointing straight ahead (called toe (in/out))is controlled and adjusted by the tie rod adjusters. generally you want a slight amount of toe in, like just a 1/16" or so, statically measured. In actual operation, the tires/wheels will tend to pull away from each other, and theoretically you'll end up with zero toe dynamically. You can get close with a tape measure, some yardsticks, and some wrenches. If you Google "aligning wheels" , you'll probably see a lot of ideas how to do it. With a keen eye, a level surface, and some care, you can get fairly close at home. Certainly, close enough to drive it to the alignment shop without scrubbing all the tread off your tires.

-