You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Icon IC 743 piston weight incorrect

- Thread starter 72DMag

- Start date

-

yellow rose

Overnight Sensation

@nm9stheham Sorry didn't get back to you sooner been away from computer. I see what you mean now. When you said pad of the rod I thought of the small end since alot of guys grind those when doing a stroker.

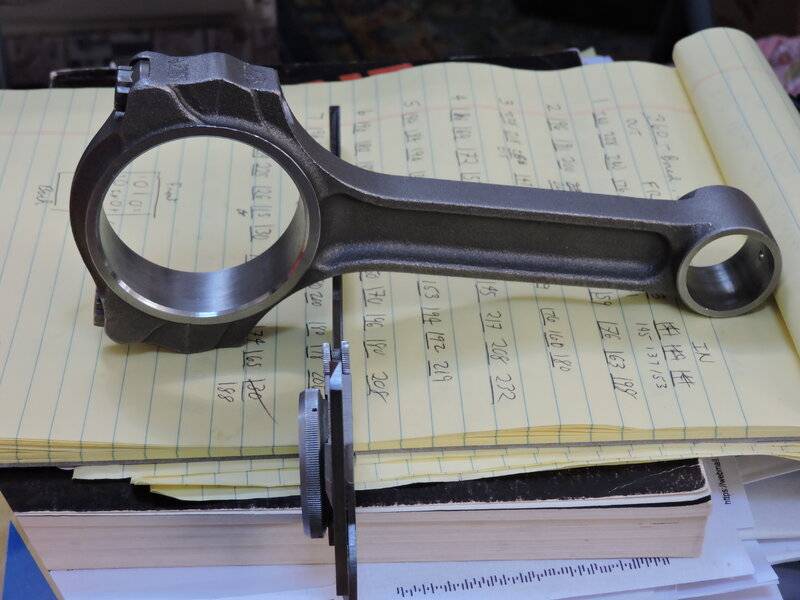

Actually you have me thinking that I could possibly make the ic743 dome pistons work. I have them boxed but didn't return yet. I think I would need to grind both the top and bottom end though. I would grind the top as pictured above and might get like 20 grams off of it If I had to guess. Then I will grind the big end of the rod to a round shape like pictured. I bet I can get 10 grams off of it which would be 20 total bobweight. Again these are just numbers I am tossing out but that takes off 40 grams and only puts me 31 grams heavier than stock. So it will be close.

I could also use the 18 grams lighter wrist pin but with high compression sounds like a bad idea to me and not going to consider it.

I will be at the shop tmrow and I have some scrap magnum rods I can use for testing. Will measure cap weight by itself too and see what my final weights turn out to be. Thanks!

View attachment 1715537348

Funny thing about the wrist pin being too light and/or flexing...I ran across a thread on Yellow Bullet a few days after I posted about the light pin deal.

Anyhoo...this guy buys a I believe a complete car or truck or something and made one or two hits on it and then it broke a rod right above the big end. He was calling it a rod failure, which it was, but it didn’t fail because the rod was junk.

The upshot of all this is the rods were Molnar pieces which are great parts and the owner the guts to send the parts to Molnar to be inspected, even though the nattering nabobs said Molnar would just blow him off and lie to him.

The results were on the inspection the pin had seized in the rod and literally ripped the rod in two. I personally never seen that happen, but on several occasions I’ve been working on engines that have ripped the pin eye out of the rod, and also ripped the top off the piston.

So lighter isn’t always better. It has a dark side that if you dare go there, what happens is usually expensive.

nm9stheham

Well-Known Member

I personally would do the lighter pin if you are not leaning on the engine hard. The failure mode described is right, but it takes some loading to get there..... But maybe save that for last.@nm9stheham Sorry didn't get back to you sooner been away from computer. I see what you mean now. When you said pad of the rod I thought of the small end since alot of guys grind those when doing a stroker.

Actually you have me thinking that I could possibly make the ic743 dome pistons work. I have them boxed but didn't return yet. I think I would need to grind both the top and bottom end though. I would grind the top as pictured above and might get like 20 grams off of it If I had to guess. Then I will grind the big end of the rod to a round shape like pictured. I bet I can get 10 grams off of it which would be 20 total bobweight. Again these are just numbers I am tossing out but that takes off 40 grams and only puts me 31 grams heavier than stock. So it will be close.

I could also use the 18 grams lighter wrist pin but with high compression sounds like a bad idea to me and not going to consider it.

I will be at the shop tmrow and I have some scrap magnum rods I can use for testing. Will measure cap weight by itself too and see what my final weights turn out to be. Thanks!

View attachment 1715537348

Glad you have the parts to try. It'll be very interesting to see what you can do. BTW, be aware that almost all of the beam is small end weight. Take a rod and lay it flatwise (like your photo above) and then place it on a thin edge perpendicular to the long axis of the rod. Where the rod balances on the edge will be just above the big end, and when you find that point, everything above that is small end weight, and everything below that (all around the big end) is big end weight. So find that balance point and take careful note of where you are taking the weight off, so you can determine how much bobweight you are actually saving. Remember, you get 1 gram per gram from the small end, and 2 grams per gram from the big end.

If you have an old piston, see how much you can get out by drilling the pin bosses with a few holes. It will not be a lot but that is another spot. There may be some more spots on the pistons. Yeah, I know... you have to be brave to hack into a new set of pistons; just don't put a hole saw through the top LOL, Somehting esle to save for last....

BTW, that rod you show above is a SCAT or Eagle and the material is stronger. So I'd not go that far in material removal.

nm9stheham

Well-Known Member

BTW, here is a SCAT rod showing the approximate separation point between the big and small end weight parts. It would be more accurate if I had put it flat on the edge.

pishta

I know I'm right....

The guy at an import race shop takes the marked rods apart, balances all the tops to the lowest weight off the tip pad, and then balances all the bottoms to the lowest weight off the bottom pad. Said he did this forever and it always worked. It sure is easier than rigging up our jigs and trying to get repeatable weights using a fixed or swinging pivot, consumer grade scales, etc.

Notice the last line of the post #19 that states the magnum rod is thinner at the little end so if you buy Magnum pistons for LA rods youll have to closely check side clearance of rods to block. I took weight out of the end of the pin (actually making them 2mm shorter as it was the free end of the pin and it was a press fit pin on the rod so it didnt move once it was installed on the journal. My MP pistons and pins were up to 12g variance from each other!

Notice the last line of the post #19 that states the magnum rod is thinner at the little end so if you buy Magnum pistons for LA rods youll have to closely check side clearance of rods to block. I took weight out of the end of the pin (actually making them 2mm shorter as it was the free end of the pin and it was a press fit pin on the rod so it didnt move once it was installed on the journal. My MP pistons and pins were up to 12g variance from each other!

nm9stheham

Well-Known Member

And keep in mind that the ring pack for those ICON's weighs a few grams less than the stock Magnum ring pack. The top 2 ring are thinner. So there is a few more grams. If you have the rings, weigh them.

nm9stheham

Well-Known Member

Hey Pishta... interesting info on the import rod work. However, for 4 cylinder inlines (or any inline), the reciprocating and rotating weight parts are not separated out; the whole piston-rod assemblies are weight matched against each other. So unless he is working on imports like V6 Z engines, etc. his technique does nothing of benefit (that I am aware of).The guy at an import race shop takes the marked rods apart, balances all the tops to the lowest weight off the tip pad, and then balances all the bottoms to the lowest weight off the bottom pad. Said he did this forever and it always worked. It sure is easier than rigging up our jigs and trying to get repeatable weights using a fixed or swinging pivot, consumer grade scales, etc.

Notice the last line of the post #19 that states the magnum rod is thinner at the little end so if you buy Magnum pistons for LA rods youll have to closely check side clearance of rods to block. I took weight out of the end of the pin (actually making them 2mm shorter as it was the free end of the pin and it was a press fit pin on the rod so it didnt move once it was installed on the journal. My MP pistons and pins were up to 12g variance from each other!

Yes, that is plenty of piston/pin variance! The performance brands usually come very closely matched.

And interesting on the pin mods.... as long as you keep the weight bearing length of the pin in the pin bore adequate and keep the pin centered (and not floating too much back an forth) then that can work. The older pistons seemed to keep around 0.7" of weight bearing length between pin and pin bore, but I've seen just under 0.5" in modern engines. It would be interesting to survey a whole lot of pistons at different power levels to see what is used.

pishta

I know I'm right....

I asked him in a comment about it and he replied the same way, on a 180 crank in a 4 banger, they self balance if the piston packs are neutral (1+4=2+3). a 120 crank (straight 6) and a 90 crank (V8) do require a little more math. Ill put this out to anyone trying to do rods at home: nm9stheham and I found repeatablilty the hardest part in building rod jigs. both of us had failures and successes but I for one never found a rock solid platform (or maybe more so a digital scale) that would give me 3 for 3 +- .1 or even .2g resolution. I accepted .3 at that and moved on. We all know Mopar didnt go this far at the factory so meh.....made me feel better trying and its a heck of a lot closer than factory specs.Hey Pishta... interesting info on the import rod work. However, for 4 cylinder inlines (or any inline), the reciprocating and rotating weight parts are not separated out; the whole piston-rod assemblies are weight matched against each other. So unless he is working on imports like V6 Z engines, etc. his technique does nothing of benefit (that I am aware of).

s.And keep in mind that the ring pack for those ICON's weighs a few grams less than the stock Magnum ring pack. The top 2 ring are thinner. So there is a few more grams. If you have the rings, weigh them.

OEM magnum pistons use metric rings,,,they will be lighter then the 1/16 rings used by ICON 741 pistons.

nm9stheham

Well-Known Member

Thanks AAR... made me re-look at this.

5.2's are listed at 5/64, which is what I was looking at before. I assumed 5.9 and 5.2 were the same; that is my mistake.

I see that the 5.9's are 1.5 mm.... so .059" vs .0625" thick.. What I don't know is the width. Do you have some weight numbers be chance?

5.2's are listed at 5/64, which is what I was looking at before. I assumed 5.9 and 5.2 were the same; that is my mistake.

I see that the 5.9's are 1.5 mm.... so .059" vs .0625" thick.. What I don't know is the width. Do you have some weight numbers be chance?

nm9stheham

Well-Known Member

As I understand it (per my local machinist of 40+ years), an inline 6 is like an inline 4.... no reciprocating weight is needed. A V6 is like a V8 where you have to separate out the reciprocating weight and use a factor of 35% for the V6 versus 50% for a V8.I asked him in a comment about it and he replied the same way, on a 180 crank in a 4 banger, they self balance if the piston packs are neutral (1+4=2+3). a 120 crank (straight 6) and a 90 crank (V8) do require a little more math. Ill put this out to anyone trying to do rods at home: nm9stheham and I found repeatablilty the hardest part in building rod jigs. both of us had failures and successes but I for one never found a rock solid platform (or maybe more so a digital scale) that would give me 3 for 3 +- .1 or even .2g resolution. I accepted .3 at that and moved on. We all know Mopar didnt go this far at the factory so meh.....made me feel better trying and its a heck of a lot closer than factory specs.

Yes, separating the reciprocating from rotation weight in the rods is the challenge. It took a while to get my jig set up to where I have high confidence in it.... so the total rod weight was consistently within 2 grams of the reciprocating + rotating weights. Even Smokey Y. says that is hard...

But, the way the OP is planning (I think) is to take the same weight off one end, then the same weight off the other end. So he won't be distorting the weight difference between the 2 ends.

pishta

I know I'm right....

Might as well seperated the rods and just weight the tops and equalize and then weight the caps and equalize if its all straight forward weight as your guy (who knows more than me on straight 6 engines for sure) says its the same as a 4. No jig necessasary? Its a forging, there is probably little difference in the beam if they have not been polished and stress relieved. all the varience is taken up in the balance pads.But, the way the OP is planning (I think) is to take the same weight off one end, then the same weight off the other end. So he won't be distorting the weight difference between the 2 ends.

Shaker223

Boost Rules

Any build updates? I've been working on an E85 360LA engine.

Don't know about 743 but the 741 is advertised at 530grams and 118gram pin, according to /CNC Motorsports.com....sincerly JesseBuilding up the 360 and purchased the icon ic743 pistons to significantly up the compression to run e85.

According to icon pistons catalog the piston should weigh 492 grams and the wrist pin should be 118 grams. After getting the pistons in and weighing them they are much much heavier than advertised!! On average the piston alone weighs 563 grams and the wrist pins average out to 125 grams.

Does anyone have experience with these pistons?? I am going to call icon on Tuesday but 71 grams heavier than advertised is crazy and can't be used with my stock balanced magnum 360.

Before any responses yes the scale is correct and zeroed out. I place some connecting rods on it to verify. Thanks

I can't see ICON being off on the weight. I probably sell 30 set of ICON piston a year and I've never had any issue with weight off that much. I am going to say your scale is off.

Order yourself a 500 gram calibration weight from Amazon for $11.99

Bonvoisin 500g Calibration Weight for Digital Scale, Class M1, Carbon Steel, Chrome Finish (500g)

I purchased one when a friend told me my scale was off and I told him I know your's is off. I checked mine and I was dead on 500 grams. When we checked his it was off 55 grams.

Using a claibration weight is the only true way to know if your scale is reading correctly. I am going to say it's off.

Tom

-