You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Intake manifold won't seal - How do I check it ?

- Thread starter duster360

- Start date

-

was the top of your block decked ,could be something misaligned there?

Block was not decked. The heads on this engine are also the ones it came with from the factory.

Heres a question and its something Ive never read any talk about. When you replaced the heads how thick of a head gasket did you use ? If you went from a stock .028" to a .040" fell pro I would think that would cause the intake to need a gasket around .012" wider then stock also. Ive never heard of this being an issue before oddly enough.

The head gaskets are the .040" Felpro. I have never seen this problem before either. But my machinist says he has been through this several times. He was a second pair of eyes that varified it is leaking.

Woods74

Broke Senior

Damn it must be nice to have someone you trust touching your car. Doesn't happen to me. Good luck!

DId I miss this, is it a new or used intake?

Brand new intake.

Damn it must be nice to have someone you trust touching your car. Doesn't happen to me. Good luck!

I have known him most of my life and he is one of the few I trust to work on my engine.

EL5DEMON340

Well-Known Member

How does it fit, without the end gaskets on, just the head gaskets?

I don't use the end gaskets, just RTV.

70Duster440

Well-Known Member

Original intake bolts - fully threaded?

Simple procedure. Here's how you do it. You will need two tools. A short bullet level and a dial type angle finder. Harbor Freight has both on the cheap. First, whether the engine is on a stand or in the car does not matter. Level the engine up from front to back. You need to cut a straight section of 2x4 long enough to span the intake valley front to back. Lay the 2x4 sideways on the block parallel with the crankshaft. Get your level and put it on the 2x4 and level the engine up front to back.

Next, put the level on the front block face where the intake meets where you would normally run a bead of RTV to seal it. Level the engine upside to side. Double check the front to back measurement and make any necessary corrections. Might want to double check the side to side if you make corrections. After it is good and level both ways, take your angle finder and measure the angle of the intake face and write that number down.

Now that you have the cylinder head intake face angle, time to move onto the intake. Flip it upside down on some good level concrete. Get it level front to back and side to side just like you did the engine and find the intake face angle. Write that number down.

The angles may not be different. All that maybe wrong is the heads and or block may have been milled at some point in the past. You can find that out, too. Take the intake and place it on the engine with gaskets in place. Line up the intake bolt holes. If they do not line up in the center of the intake bolt holes of the intake, the heads and or block have likely been milled. Remove the gaskets and try it again. If the holes are good and close to or on center, there's your answer. Mic the intake gaskets and have the intake milled however thick the gaskets are to whatever angle your first angle was for the engine and your problem is solved.

Next, put the level on the front block face where the intake meets where you would normally run a bead of RTV to seal it. Level the engine upside to side. Double check the front to back measurement and make any necessary corrections. Might want to double check the side to side if you make corrections. After it is good and level both ways, take your angle finder and measure the angle of the intake face and write that number down.

Now that you have the cylinder head intake face angle, time to move onto the intake. Flip it upside down on some good level concrete. Get it level front to back and side to side just like you did the engine and find the intake face angle. Write that number down.

The angles may not be different. All that maybe wrong is the heads and or block may have been milled at some point in the past. You can find that out, too. Take the intake and place it on the engine with gaskets in place. Line up the intake bolt holes. If they do not line up in the center of the intake bolt holes of the intake, the heads and or block have likely been milled. Remove the gaskets and try it again. If the holes are good and close to or on center, there's your answer. Mic the intake gaskets and have the intake milled however thick the gaskets are to whatever angle your first angle was for the engine and your problem is solved.

skrews

Well-Known Member

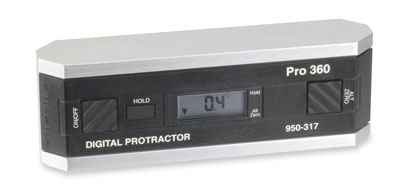

Use one of these to find the angle difference. Then have intake milled to correct angle.

Just going to throw this out there............

Every one seams to thing it is a intake leak, and the leak is from the lifter bore, side Right!?

I have not heard any thing about all the BLUE smoke that should be pouring out the tail pipe(s) or the oil soaked spark plugs

Every one seams to thing it is a intake leak, and the leak is from the lifter bore, side Right!?

I have not heard any thing about all the BLUE smoke that should be pouring out the tail pipe(s) or the oil soaked spark plugs

70Duster440

Well-Known Member

I have not heard any thing about all the BLUE smoke that should be pouring out the tail pipe(s) or the oil soaked spark plugs

That relates to my question about the intake bolts. Had a 340 Challenger in which the fully threaded intake bolts were "replaced" with bolts that had a short shoulder on them. Bolts were tight, all seemed well when, in fact, the shoulder was stopping the bolt from threading into the head further - reduced clamping of the gasket. Car ran and idled okay. But on the highway when you let off the gas it produced a pretty impressive James Bond style smoke screen as engine vacuum sucked oil past the gasket at the bottom of the ports.

EL5DEMON340

Well-Known Member

It may not smoke bad until it's revved up high. He didn't state if it was or wasn't smoking

I think there is a machining defect with the intake. You can get a cheap angle finder from Home Depot. Once you get the angle call the "tech dept" for whomever made the intake. Let them tell you the correct angle 1st before telling them your angle.

Good luck, I keep checking in hoping you finger out the solution!

Good luck, I keep checking in hoping you finger out the solution!

skrews

Well-Known Member

These are not accurate enough,

EL5DEMON340

Well-Known Member

measured the angle on my mopar 6 pack its 48 degrees, also checked it to a known good torker II and it was the same. you can also see the sloppy port. I would assume if you lay the protractor on the end rail and measure the head intake face it should be just about 48 degrees also.

Attachments

I have an update. I took the measurement that EL5demon got for me. I measured my intake and came up with 48* on all 4 corners just like he measured. So that means the intake will milled to the correct angle.

I noticed a dark outline around the heat crossover port on the intake, but it was off centered a some. I sat the gasket on the intake and matched it up with the heat crossover outline. I noticed how the gasket sat very low on the intake. So I got in some better lighting and looked a lot harder at the gaskets. I can see the outlines very well toward the top of the intake and I looked toward the bottom of the gasket and that is when I saw what I think was the problem.

I noticed a dark outline around the heat crossover port on the intake, but it was off centered a some. I sat the gasket on the intake and matched it up with the heat crossover outline. I noticed how the gasket sat very low on the intake. So I got in some better lighting and looked a lot harder at the gaskets. I can see the outlines very well toward the top of the intake and I looked toward the bottom of the gasket and that is when I saw what I think was the problem.

66dartgt

Well-Known Member

I had a similar issue with the 360 I put in my 73 sport. Top of intake gasket crushed down nicely - bottom did not and leaked oil into the intake ports. Tried using sealants on new gaskets, thicker gaskets etc - no good. I knew I had machined the head for compression .030", but figured it was not enough to need a correction on the intake face of the head. WRONG. I never was able to get the intake to seal properly until I had the intake machined (.095 per .010) and it fixed it. Sealed up perfectly.

On my manifold (dual plane Weiand) I was able to site down a couple of the intake runners and see the misalignment from the carb plenum. If you port matched the intake and head to the gasket, you'll see it.

On my manifold (dual plane Weiand) I was able to site down a couple of the intake runners and see the misalignment from the carb plenum. If you port matched the intake and head to the gasket, you'll see it.

I still have to check the head angle to positive. I noticed that the intake gaskets on the bottom side that there was a crimp line running right through the area where the sealing ring goes around the gasket port. The gaskets are sitting way low on the head when I put the intake on. The roof of the ports on the intake manifold were partially covered with gasket and the lower part of the gasket is hanging down past the bottom of the manifold. I have ordered some gasgacinch to help keep the gaslkets in place next time the manifold goes on. I am also going to do a little more checking before installation.

-