Earlie A

Well-Known Member

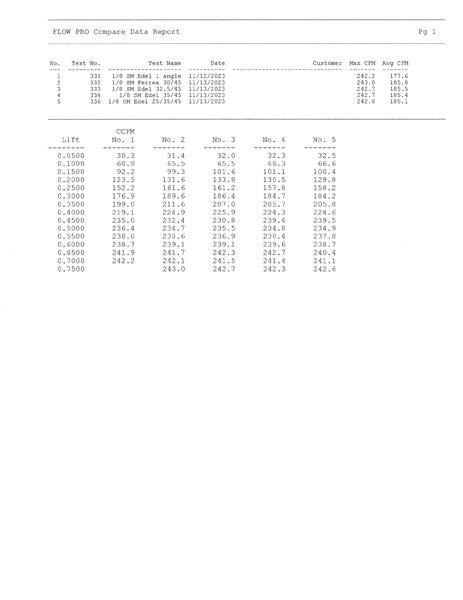

Here's a little flow bench data that may be of interest. I was curious about the effect of changing the back cut angle on intake valves, so here's the test:

Out of the box Speedmaster small block mopar head (cylinder position 1 or 8)

2.02 intake valve

Test pressure: 28 in Hg

Test 1: Stock Edelbrock valve, 45 degree seat 0.100" wide

Test 2: Ferrea valve, 45 degree seat 0.060" wide, 30 degree back cut

Test 3: Edelbrock valve, 45 degree seat 0.060" wide, 32.5 degree back cut

Test 4: Edelbrock valve, 45 degree seat 0.060" wide, 35 degree back cut

Test 5: Edelbrock valve, 45 degree seat 0.050" wide, back cuts of 25 and 35 degrees @ 0.040" each

Darin Morgan says a back cut on the intake valve is the easiest 10-15 hp you will ever make. It sure increased the low and mid lift flow numbers. In this situation the actual measure of the back cut angle doesn't seem to matter much.

Out of the box Speedmaster small block mopar head (cylinder position 1 or 8)

2.02 intake valve

Test pressure: 28 in Hg

Test 1: Stock Edelbrock valve, 45 degree seat 0.100" wide

Test 2: Ferrea valve, 45 degree seat 0.060" wide, 30 degree back cut

Test 3: Edelbrock valve, 45 degree seat 0.060" wide, 32.5 degree back cut

Test 4: Edelbrock valve, 45 degree seat 0.060" wide, 35 degree back cut

Test 5: Edelbrock valve, 45 degree seat 0.050" wide, back cuts of 25 and 35 degrees @ 0.040" each

Darin Morgan says a back cut on the intake valve is the easiest 10-15 hp you will ever make. It sure increased the low and mid lift flow numbers. In this situation the actual measure of the back cut angle doesn't seem to matter much.

Attachments

Last edited: