Well I was driving on the freeway today when all of a sudden the duster started handling wonky and wandering erratically, like if its alignment was off somehow.

After driving back home. I tore into the front suspension.

Yep upper ball joints are gone and the lower balljoints are not looking to good either. (these ball joints are only a year old)

Bushings are ok.

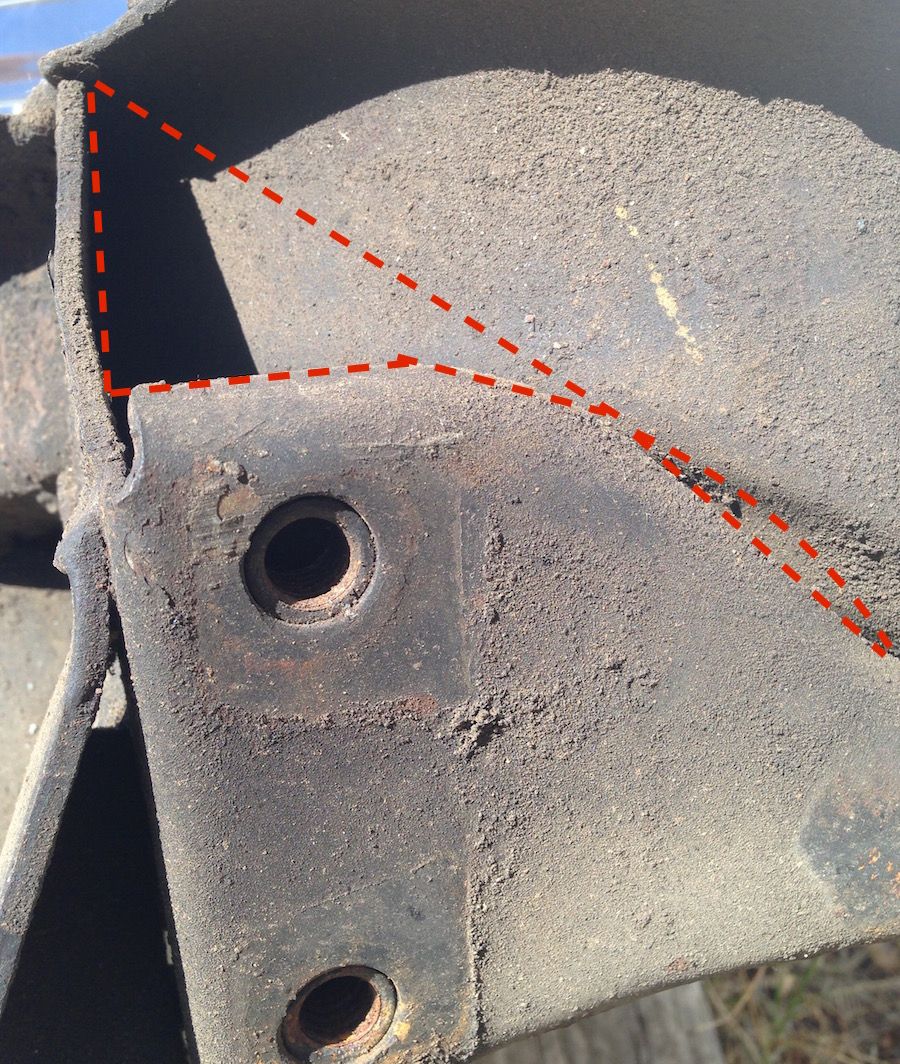

Then I found this gem on the drivers side. This is where the lower control arm spindle goes in to.

View attachment 20160402_181907[1].jpg

View attachment 20160402_181918[1].jpg

View attachment 20160402_181955[1].jpg

SO...

Is it even fixable? Like maybe welding around it or is it even recommended?

Or am I better off getting another K-member?

I know QA1 sells a tubular K-Member for like $600... *ouch*

After driving back home. I tore into the front suspension.

Yep upper ball joints are gone and the lower balljoints are not looking to good either. (these ball joints are only a year old)

Bushings are ok.

Then I found this gem on the drivers side. This is where the lower control arm spindle goes in to.

View attachment 20160402_181907[1].jpg

View attachment 20160402_181918[1].jpg

View attachment 20160402_181955[1].jpg

SO...

Is it even fixable? Like maybe welding around it or is it even recommended?

Or am I better off getting another K-member?

I know QA1 sells a tubular K-Member for like $600... *ouch*