NO LOW END POWER.

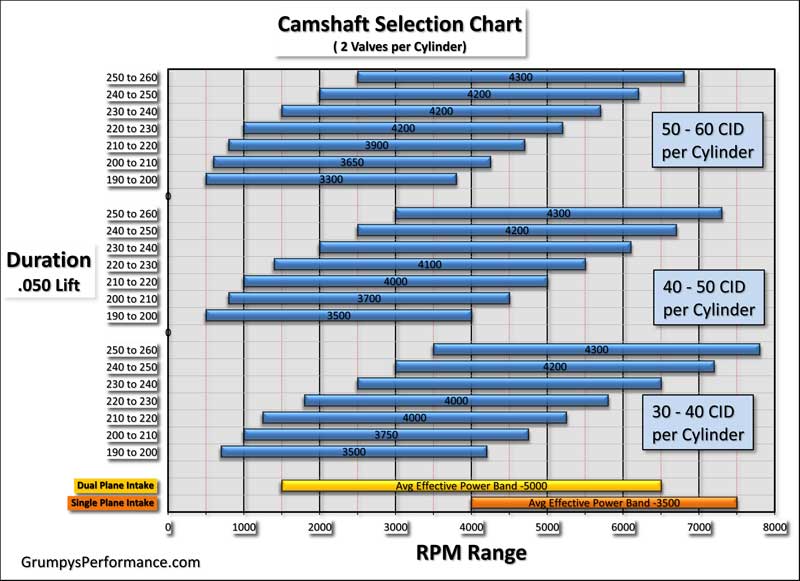

Got 318 1984 Police edition motor used, stored heated garage. Put in 69 Dart project. 727 trans rebuilt bought from member. Didnt touch lower end or heads. 120lbs psi all cylinders, added 468/ 268 approx. purple shaft cam. hooker 1 7/8 headers. Proform 4bbl/action + Weiand intake. Proform electronic ign. Stock TC, but had 2500 stall before i changed, same problem.

This engine runs great, shifts great. Can drive all day. But no real power until after 2200RPM.

I was told the cam could be retarded due to chain (new) stretch? Off a tooth?

Did all tests to prove wrong,Maybe. Deadstop TDC test was Accurate. Putting #6 cylinder TDC compression stroke and Measuring #1 cylinder spring tension difference of intake/exhaust

of .030 int.-.060 ex. was good. Ive put bigger cams in stock engines with no issue.

Tried points dist./different good carbs im lost for answers

Help before I put bigblock in...................

PS. 3.23 suregrip 8 3/4 rear

Thanks D

Got 318 1984 Police edition motor used, stored heated garage. Put in 69 Dart project. 727 trans rebuilt bought from member. Didnt touch lower end or heads. 120lbs psi all cylinders, added 468/ 268 approx. purple shaft cam. hooker 1 7/8 headers. Proform 4bbl/action + Weiand intake. Proform electronic ign. Stock TC, but had 2500 stall before i changed, same problem.

This engine runs great, shifts great. Can drive all day. But no real power until after 2200RPM.

I was told the cam could be retarded due to chain (new) stretch? Off a tooth?

Did all tests to prove wrong,Maybe. Deadstop TDC test was Accurate. Putting #6 cylinder TDC compression stroke and Measuring #1 cylinder spring tension difference of intake/exhaust

of .030 int.-.060 ex. was good. Ive put bigger cams in stock engines with no issue.

Tried points dist./different good carbs im lost for answers

Help before I put bigblock in...................

PS. 3.23 suregrip 8 3/4 rear

Thanks D